Hydraulic cylinder of carbon fiber composite material

A technology of composite materials and composite material layers, applied in the field of carbon fiber composite hydraulic cylinders, can solve the problems of unsatisfactory strength, stiffness, fatigue resistance and safety, and heavy weight of all-metal hydraulic cylinders, so as to solve the problem of light weight and save Power and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

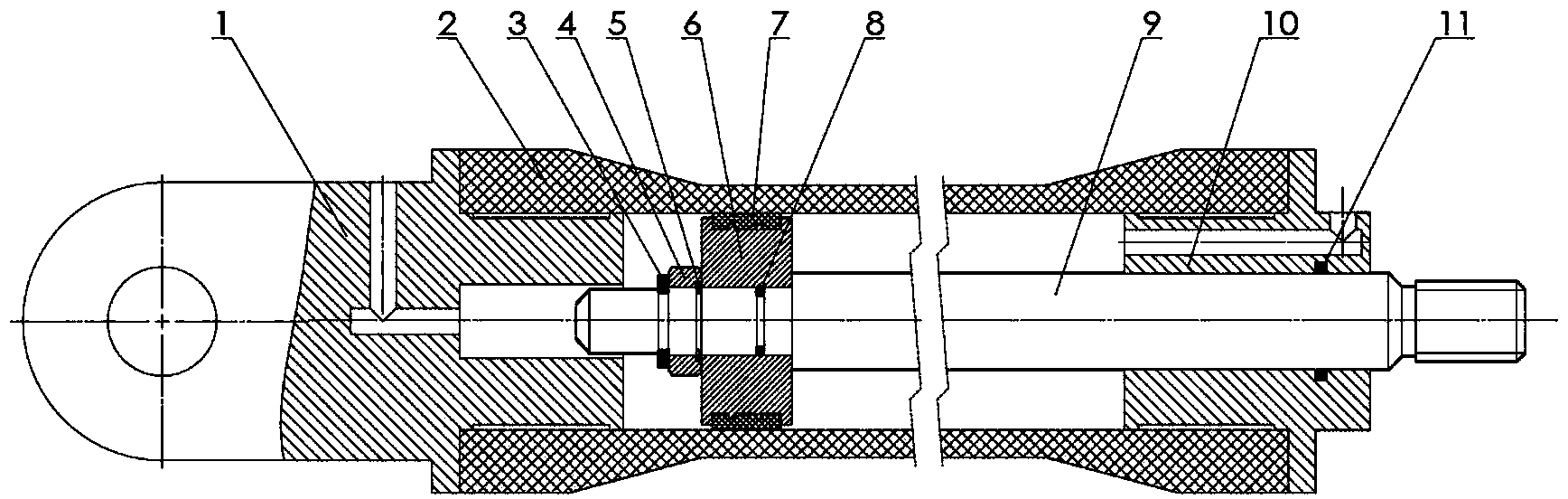

[0025] Carbon fiber composite material hydraulic cylinder provided by the present invention, its structure is basically the same as the prior art, see figure 1 , mainly composed of cylinder bottom 1, cylinder body 2, spring retaining ring 3, collar 4, snap ring 5, piston 6, sealing ring 7, O-shaped sealing ring 8, piston rod 9, cylinder head 10, dustproof ring 11 , wherein: the cylinder block 2 is made of high-strength carbon fiber precursor with a strength ≥ 3500MPa as a reinforcing material, a thermosetting resin as a matrix, and is made of a carbon fiber composite material layer by winding carbon fiber. The materials of cylinder bottom 1, piston 6 and cylinder head 10 are all made of high-strength aluminum alloy with strength ≥ 500 MPa, and the material of piston rod 9 is high-strength metal material.

[0026] The carbon fiber winding molding proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com