Integrated micro heat exchanger component with drying filtering and throttling functions

A heat exchanger and filter element technology, applied in the field of integrated heat exchanger components, can solve problems such as difficult pipeline layout and welding, mismatched heat transfer, poor adaptability, etc., to achieve easy assembly, simple layout, and reliability good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

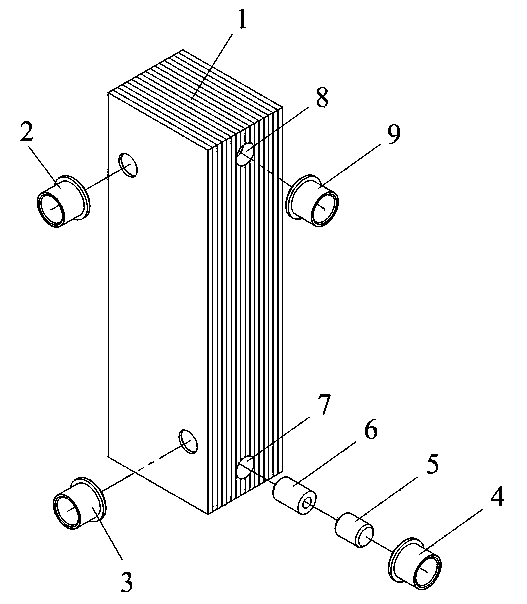

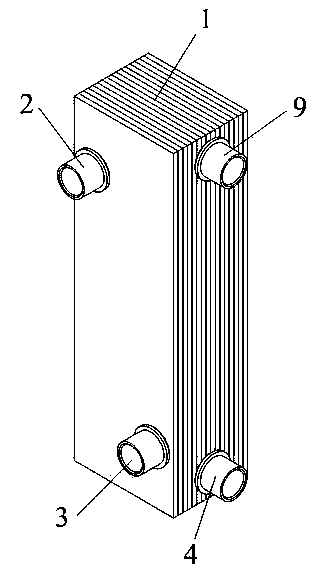

[0031] Such as figure 1 Shown, according to a specific embodiment of the present invention comprises:

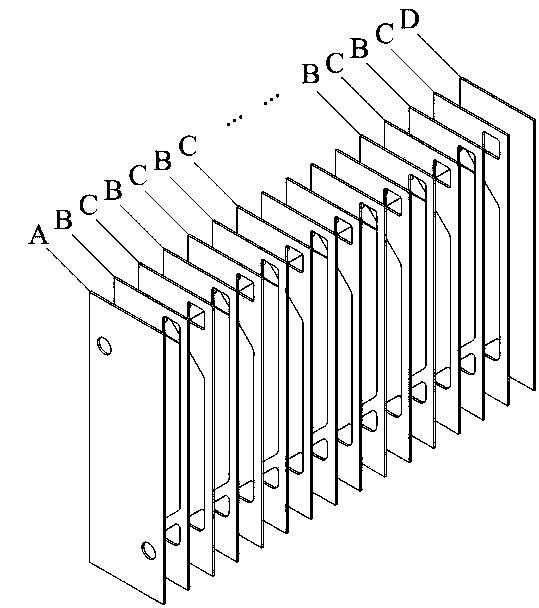

[0032] Micro-plate heat exchanger 1, fluid joint 2, fluid joint 3, refrigerant joint 4, dry filter element 5, micro-throttling element 6, refrigerant circulation hole 7 opened in the direction perpendicular to the side of the multi-layer metal sheet, in The refrigerant circulation holes 8 and the refrigerant joints 9 are opened perpendicular to the side surfaces of the multi-layer metal sheets. Among them, the micro-plate heat exchanger 1 is an entity formed by multi-layer metal thin plates (typically stainless steel thin plates with a thickness less than 1 mm) through vacuum diffusion welding, and forms interlaced refrigerant flow channels and exchange channels inside it. Hot fluid runner. The plates of the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com