Manufacturing process for dual-calcium-fortified low-fluorine brick tea

A production process and calcium strengthening technology, applied in the field of brick tea production process, to achieve the effect of increasing calcium content, reducing fluorine content, and pure taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Selection of origin of tea raw materials: Screen out teas produced in non-coal-producing areas and non-coal-burning fluorosis areas, which have relatively low fluorine content and are suitable for making low-fluorine brick tea.

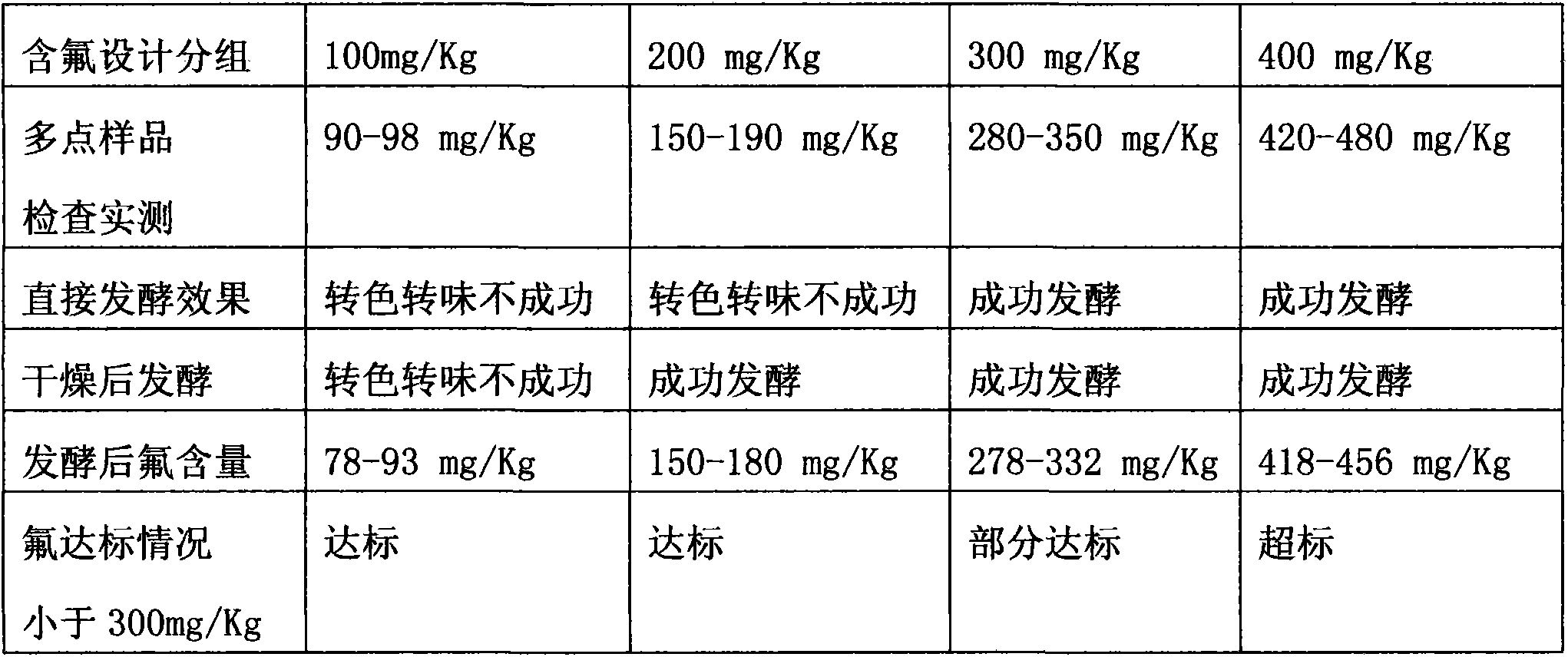

[0029] Selection ratio of tenderness: Use tea leaves with fluorine content of 100, 200, 300, 400, 500mg / Kg to conduct flowering test to determine the main raw materials. The results show that Sichuan local summer tea with 4-5 leaves per tooth as the main raw material can be fermented effectively after pretreatment.

[0030] 1. Tea picking: From June to July every year, Sichuan local summer tea with 1 bud and 4 to 5 leaves is picked by a tea picking machine; after picking, the tea leaves are dried into a loose state and temporarily stacked.

[0031] The drying method can be carried out by exposing to the sun. In the summer temperature of Sichuan, usually one day of sun exposure can meet the drying requirements. Drying with a dryer is also possi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com