Efficiently sheared, homogenized and emulsified oil powder

A technology of homogeneous emulsification and oil powder, which is applied in the fields of application, animal feed, animal feed, etc. It can solve the problems of not being able to achieve the expected effect, poor starch utilization, and milk fat rate decline, and achieve considerable social and economic benefits and fat utilization. The effect of strong ability and improved feed conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A shear homogeneous emulsified oil powder. Its formula (parts by mass) is as follows: soybean oil 39, soybean lecithin 9, 50% vitamin E 0.1, L-carnitine 0.1, bulk density below 300g / L puffed corn flour 51.8.

[0019] The preparation method is as follows: adding soybean lecithin to edible soybean oil, carrying out shear homogeneous emulsification with a homogenizer, adding vitamin E, carnitine and puffed corn flour, and fully mixing.

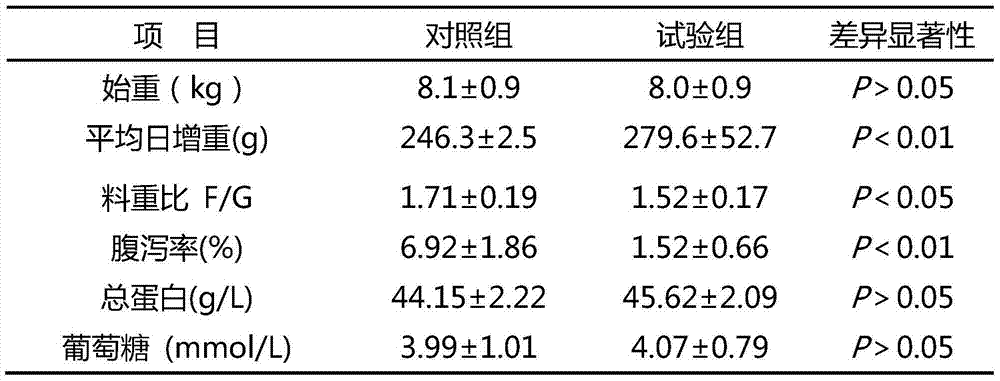

[0020] Table 1 Determination results of indicators such as piglet production performance and diarrhea rate

[0021]

[0022]

[0023] A certain number (120 heads) of weaned piglets with the same breed and small difference in body weight were selected and divided into two groups (60 heads in each group) and a control group and an experimental group. The pigs in the control group were fed with conventional diets; the pigs in the test group were fed with the shear homogeneous emulsified oil powder of the present invention (equivalent r...

Embodiment 2

[0025] The formula (parts by mass) of a shearing homogeneous emulsified oil powder is as follows: 40 soybean oil, 10 soybean lecithin, 0.1 50% vitamin E, 0.1 L-carnitine, 49.8 puffed corn flour with a bulk density below 300 g / L.

[0026] The preparation method is as follows: adding soybean lecithin to edible soybean oil, carrying out shear homogeneous emulsification with a homogenizer, adding vitamin E, carnitine and puffed corn flour, and fully mixing.

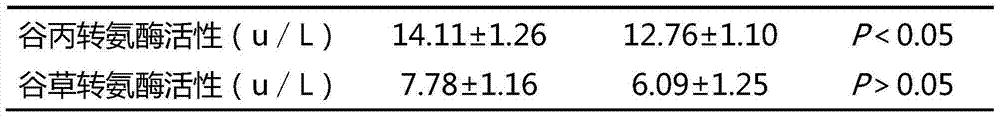

[0027] A certain number (100 heads) of weaned piglets with the same breed and small difference in body weight were selected and divided into two groups (50 heads in each group) and a control group and an experimental group. The pigs in the control group were fed with conventional diets; the pigs in the test group were fed with the shear homogeneous emulsified oil powder of the present invention (equivalent replacement of 4%-5% corn in conventional diets). The feeding period was 5 weeks, and the weight gain, feed-to-weight rat...

Embodiment 3

[0031] The formula (parts by mass) of a shearing homogeneous emulsified oil powder is as follows: 39 soybean oil, 10 soybean lecithin, 0.1 50% vitamin E, 0.1 L-carnitine, 50.8 puffed corn flour with a bulk density below 300 g / L.

[0032] The preparation method is as follows: adding soybean lecithin to edible soybean oil, carrying out shear homogeneous emulsification with a homogenizer, adding vitamin E, carnitine and puffed corn flour, and fully mixing.

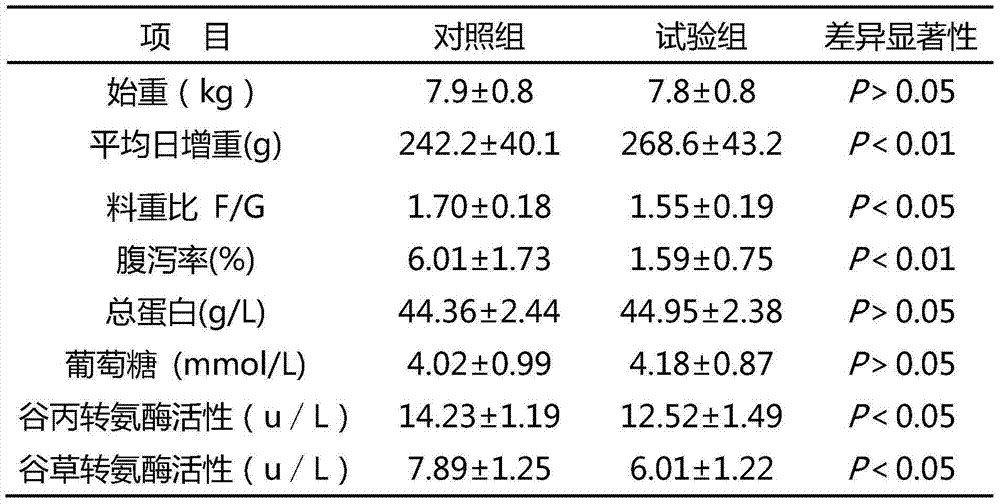

[0033] A certain number (90 heads) of weaned piglets with the same breed and small weight difference were selected and divided into two groups (45 heads in each group) and a control group and an experimental group. The pigs in the control group were fed with conventional diets; the pigs in the test group were fed with the shear homogeneous emulsified oil powder of the present invention (equivalent replacement of 4%-5% corn in conventional diets). The feeding period is 5 weeks, and the weight gain, feed-to-weight ratio (feed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com