Keratin hair conditioner and preparation method thereof

A hair conditioner and keratin technology, applied in the field of daily chemicals, can solve the problems of difficult combing, lack of luster, easy to get dirty, etc., and achieve the effect of accelerating penetration, spreading evenly, and improving softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

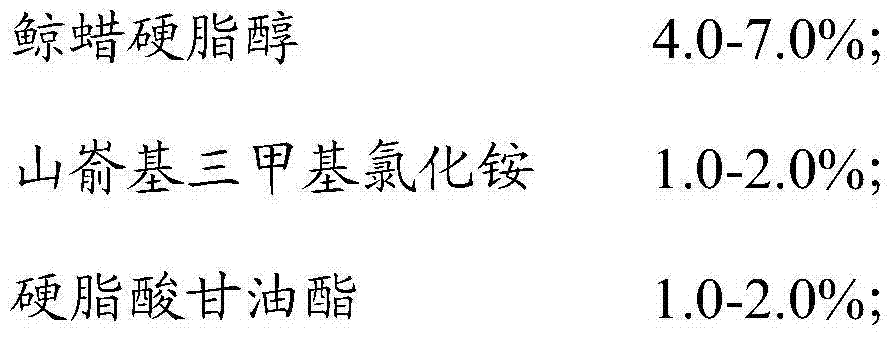

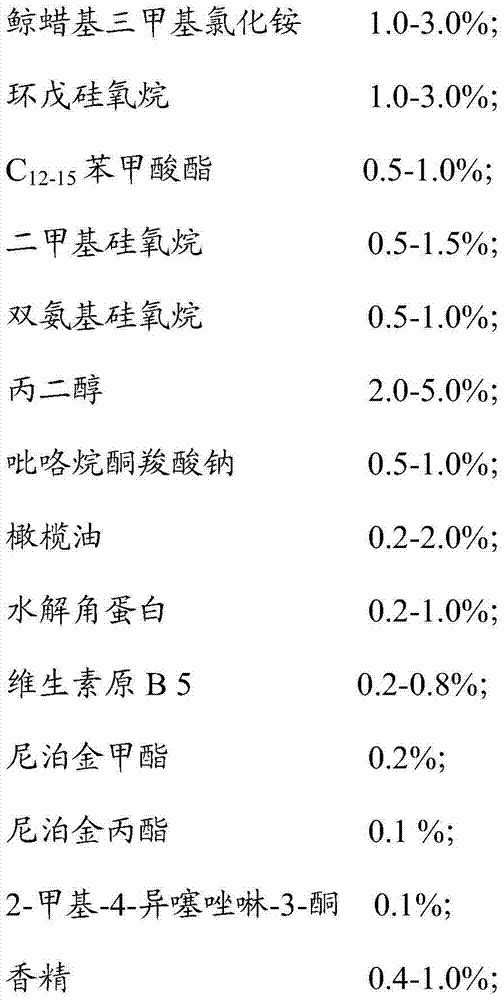

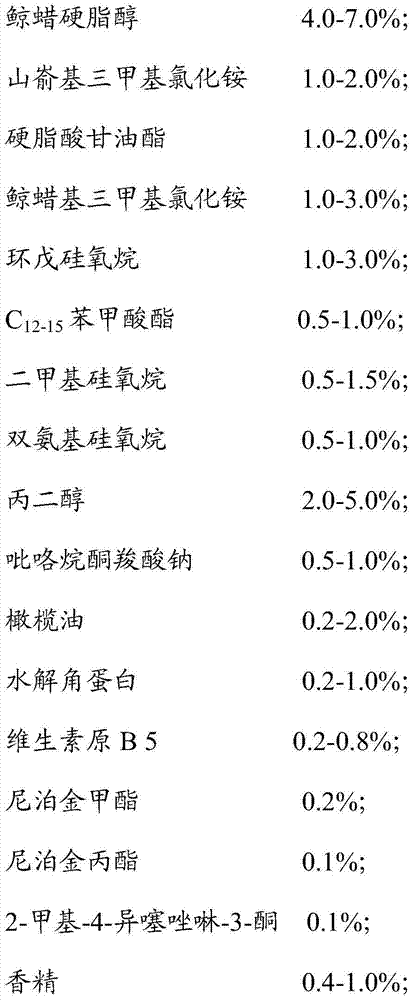

Method used

Image

Examples

Embodiment 1

[0023] Take the following raw materials by weight percentage respectively: 81.6% water, 3.0% propylene glycol, 5.0% cetearyl alcohol, 1.2% behenyl trimethyl ammonium chloride, 1.2% glyceryl stearate, 1.2% cetyl trimethyl ammonium chloride, 0.2% methylparaben, 0.1% propylparaben, 1.0% cyclopentasiloxane, 0.5% C 12-15 Parabens, 1.0% Dimethicone, 0.5% Dimethicone, 1.5% Olive Oil, 0.5% Sodium Pyrrolidone Carboxylate, 0.5% Hydrolyzed Keratin, 0.5% Provitamin B5, 0.1% 2- Methyl-4-isothiazolin-3-one and 0.4% fragrance.

[0024] Add the above-mentioned raw materials into the vacuum emulsification pot according to the following steps to prepare the keratin conditioner:

[0025] a. Add component A composed of water and propylene glycol into the water phase pot and raise the temperature to 85°C, then pump it into the emulsification pot;

[0026] b. A composition consisting of cetearyl alcohol, behenyltrimethylammonium chloride, glyceryl stearate, cetyltrimethylammonium chloride, methyl...

Embodiment 2

[0030] Take the following raw materials by weight percentage respectively: 70.5% water, 5.0% propylene glycol, 7.0% cetearyl alcohol, 2.0% behenyl trimethyl ammonium chloride, 2.0% glyceryl stearate, 2.0% cetyl trimethyl ammonium chloride, 0.2% methylparaben, 0.1% propylparaben, 2.0% cyclopentasiloxane, 1.0% C 12-15 Parabens, 1.5% Dimethicone, 1.0% Dimethicone, 2.0% Olive Oil, 1.0% Sodium Pyrrolidone Carboxylate, 1.0% Hydrolyzed Keratin, 0.8% Provitamin B5, 0.1% 2- Methyl-4-isothiazolin-3-one and 0.8% fragrance.

[0031] Add the above-mentioned raw materials into the vacuum emulsification pot according to the following steps to prepare the keratin conditioner:

[0032] a. Add component A composed of water and propylene glycol into the water phase pot and raise the temperature to 85°C, then pump it into the emulsification pot;

[0033] b. A composition consisting of cetearyl alcohol, behenyltrimethylammonium chloride, glyceryl stearate, cetyltrimethylammonium chloride, methyl...

Embodiment 3

[0037] Take the following raw materials by weight percentage respectively: 75.2% water, 4.0% propylene glycol, 6.0% cetearyl alcohol, 1.5% behenyl trimethyl ammonium chloride, 1.5% glyceryl stearate, 2.0% cetyl trimethyl ammonium chloride, 0.2% methylparaben, 0.1% propylparaben, 2.0% cyclopentasiloxane, 0.8% C 12-15 Parabens, 1.2% Dimethicone, 0.8% Diaminosiloxane, 1.8% Olive Oil, 0.8% Sodium Pyrrolidone Carboxylate, 0.6% Hydrolyzed Keratin, 0.6% Provitamin B5, 0.1% 2- Methyl-4-isothiazolin-3-one and 0.8% fragrance.

[0038] Add the above-mentioned raw materials into the vacuum emulsification pot according to the following steps to prepare the keratin conditioner:

[0039] a. Add component A composed of water and propylene glycol into the water phase pot and raise the temperature to 85°C, then pump it into the emulsification pot;

[0040] b. A composition consisting of cetearyl alcohol, behenyltrimethylammonium chloride, glyceryl stearate, cetyltrimethylammonium chloride, me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com