Medical sponge dressing and preparation method thereof

A technology of sponge and composite material, applied in the field of medical sponge dressing and its preparation, can solve the problems of lack of antibacterial efficacy, biocompatibility, and lack of antibacterial properties, achieve lasting and efficient antibacterial effect, promote healing, and sterilize good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

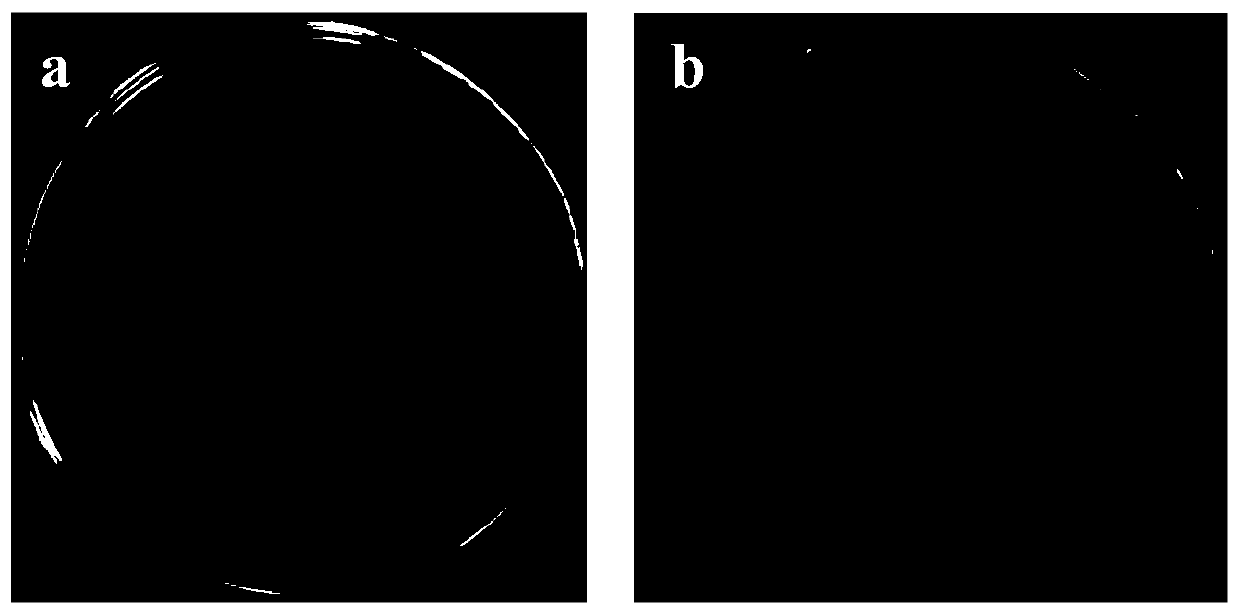

Image

Examples

Embodiment 1

[0057] (1) Dissolve the freeze-dried aloe powder in double-distilled water to obtain a 1% aloe aqueous solution, and store it in a 4°C refrigerator for later use;

[0058] (2) A polyvinyl alcohol material with a molecular weight of 60,000 and an alcoholysis degree of 99.9% was dissolved in distilled water at 90°C to obtain an aqueous solution of polyvinyl alcohol with a mass concentration of 10%;

[0059] (3) Mix the aloe aqueous solution obtained in step (1) with the polyvinyl alcohol aqueous solution obtained in step (2) to obtain the first mixed solution, add polyhexamethylene hydrochloric acid to the first mixed solution, and stir evenly to obtain the second mixed solution mixture;

[0060] (4) Inject the second mixed solution into the polytetrafluoroethylene mold, the thickness of the second mixed solution in the polytetrafluoroethylene mold is 50 μm, let stand at 4°C for 4h, then freeze at -80°C for 24h, and then freeze at 25°C Thaw at ℃ for 4 hours to obtain the gel, ...

Embodiment 2

[0065] (1) Dissolve the freeze-dried aloe powder in double-distilled water to obtain a 2% aloe aqueous solution, and store it in a 4°C refrigerator for later use;

[0066] (2) Dissolve polyvinyl alcohol material with a molecular weight of 200,000 and an alcoholysis degree of 88% in distilled water at 90°C to obtain an aqueous solution of polyvinyl alcohol with a mass concentration of 25%;

[0067] (3) Mix the aloe aqueous solution obtained in step (1) with the polyvinyl alcohol aqueous solution obtained in step (2) to obtain the first mixed solution, add polyhexamethylene hydrochloric acid to the first mixed solution, and stir evenly to obtain the second mixed solution mixture;

[0068] (4) Inject the second mixed solution into the polytetrafluoroethylene mold, the thickness of the second mixed solution in the polytetrafluoroethylene mold is 500 μm, let stand at 4°C for 4h, then freeze at -20°C for 4h, and then freeze at -20°C for 4h, and then freeze at 30°C Thaw at ℃ for 1 ...

Embodiment 3

[0070] (1) Dissolve the freeze-dried aloe powder in double-distilled water to obtain a 0.1% aloe aqueous solution, and store it in a 4°C refrigerator for later use;

[0071] (2) Dissolving polyvinyl alcohol with a molecular weight of 100,000 and an alcoholysis degree of 88% in distilled water at 90°C to obtain an aqueous solution of polyvinyl alcohol with a mass concentration of 15%;

[0072] (3) Mix the aloe aqueous solution obtained in step (1) with the polyvinyl alcohol aqueous solution obtained in step (2) to obtain the first mixed solution, add hydroxypropyltrimethylammonium chloride chitosan in the first mixed solution, Obtain the second mixed solution after stirring evenly;

[0073] (4) Inject the second mixed solution into the polytetrafluoroethylene mold, the thickness of the second mixed solution in the polytetrafluoroethylene mold is 200μm, let it stand at 4°C for 8h, then freeze it at -60°C for 12h, and then freeze it at 30°C Thaw at ℃ for 2 hours, repeat freezing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com