Process for preparing ortho-aminophenol by virtue of continuous catalytic hydrogenation

An o-aminophenol, catalytic hydrogenation technology, applied in the preparation of organic compounds, preparation of aminohydroxy compounds, catalysts for physical/chemical processes, etc., can solve the problems of harsh reaction conditions, poor product quality, large labor, etc. The effect of less investment, higher production costs, and less labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

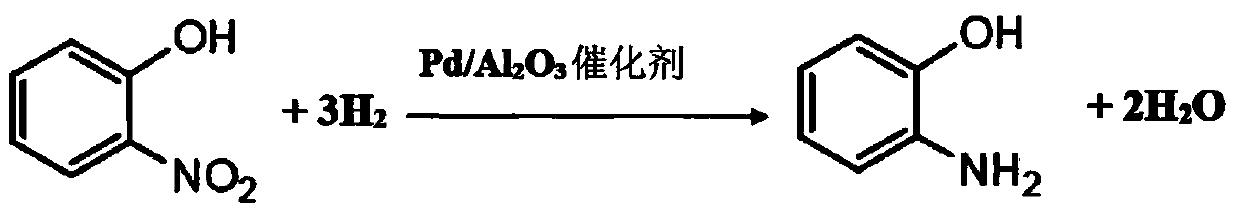

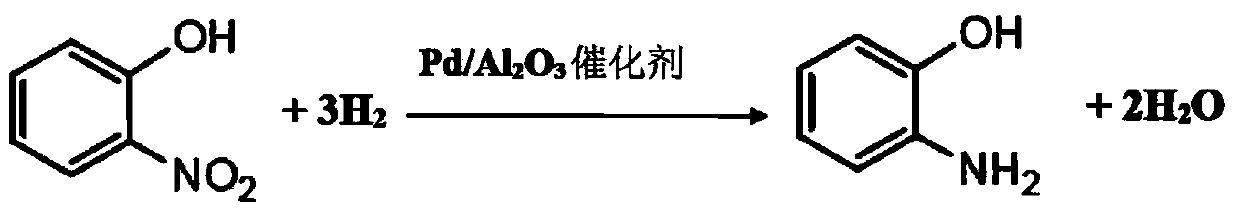

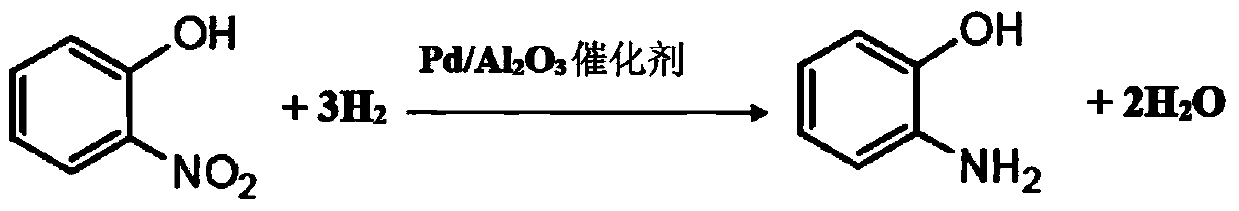

[0027] A process for preparing o-aminophenol by continuous catalytic hydrogenation, using o-nitrophenol as raw material, using Pd / Al 2 o 3 The catalyst is used for continuous catalytic hydrogenation in a fixed-bed reactor, and the target product o-aminophenol is obtained after separation and purification. Its reaction equation is:

[0028]

[0029] Specific steps include:

[0030] (1) Dissolve 1.0Kg of o-nitrophenol in 3L of ethanol-water solution with a volume fraction of 50%, preheat to 70°C, and feed continuously with a metering pump. 3 / h flow rate into the Pd / Al 2 o 3 In the fixed bed reactor of the catalyst, hydrogen gas is introduced at the same time to carry out continuous catalytic hydrogenation reduction reaction. The reaction temperature is 120°C and the reaction pressure is 1.0MPa. The reaction feed liquid enters the cooling tank and is cooled to 35°C by circulating water;

[0031] The Pd / Al 2 o 3 The mass fraction that Pd accounts for catalyst is 15% in ...

Embodiment 2

[0035] A process for preparing o-aminophenol by continuous catalytic hydrogenation, using o-nitrophenol as raw material, using Pd / Al 2 o 3 The catalyst is used for continuous catalytic hydrogenation in a fixed-bed reactor, and the target product o-aminophenol is obtained after separation and purification. Its reaction equation is:

[0036]

[0037] Specific steps include:

[0038] (1) Dissolve 1.0Kg of o-nitrophenol in 4.5L of ethanol-water solution with a volume fraction of 70%, preheat to 75°C, and feed continuously with a metering pump to 0.23m 3 / h flow rate into the Pd / Al 2 o 3 In the fixed bed reactor of the catalyst, hydrogen gas is fed at the same time to carry out continuous catalytic hydrogenation reduction reaction. The reaction temperature is 95°C and the reaction pressure is 1.5MPa. The reaction feed liquid enters the cooling tank and is cooled to 45°C by circulating water;

[0039] The Pd / Al 2 o 3 In the catalyst, the mass fraction of Pd in the cataly...

Embodiment 3

[0043] A process for preparing o-aminophenol by continuous catalytic hydrogenation, using o-nitrophenol as raw material, using Pd / Al 2 o 3 The catalyst is used for continuous catalytic hydrogenation in a fixed-bed reactor, and the target product o-aminophenol is obtained after separation and purification. Its reaction equation is:

[0044]

[0045] Specific steps include:

[0046] (1) Dissolve 1Kg of o-nitrophenol in 4.5L of ethanol-water solution with a volume fraction of 85%, preheat to 80°C, and feed continuously with a metering pump. 3 / h flow rate into the Pd / Al 2 o 3 In the fixed bed reactor of the catalyst, hydrogen gas is introduced at the same time to carry out continuous catalytic hydrogenation reduction reaction. The reaction temperature is 70°C and the reaction pressure is 2.0MPa. The reaction feed liquid enters the cooling tank and is cooled to 38°C by circulating water;

[0047] The Pd / Al 2 o 3 The mass fraction that Pd accounts for catalyst is 20% in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com