Molecular ferroelectric film and method of solution soaking growth thereof

A technology of molecular ferroelectricity and growth method, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as molecular ferroelectric thin films that have not been introduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

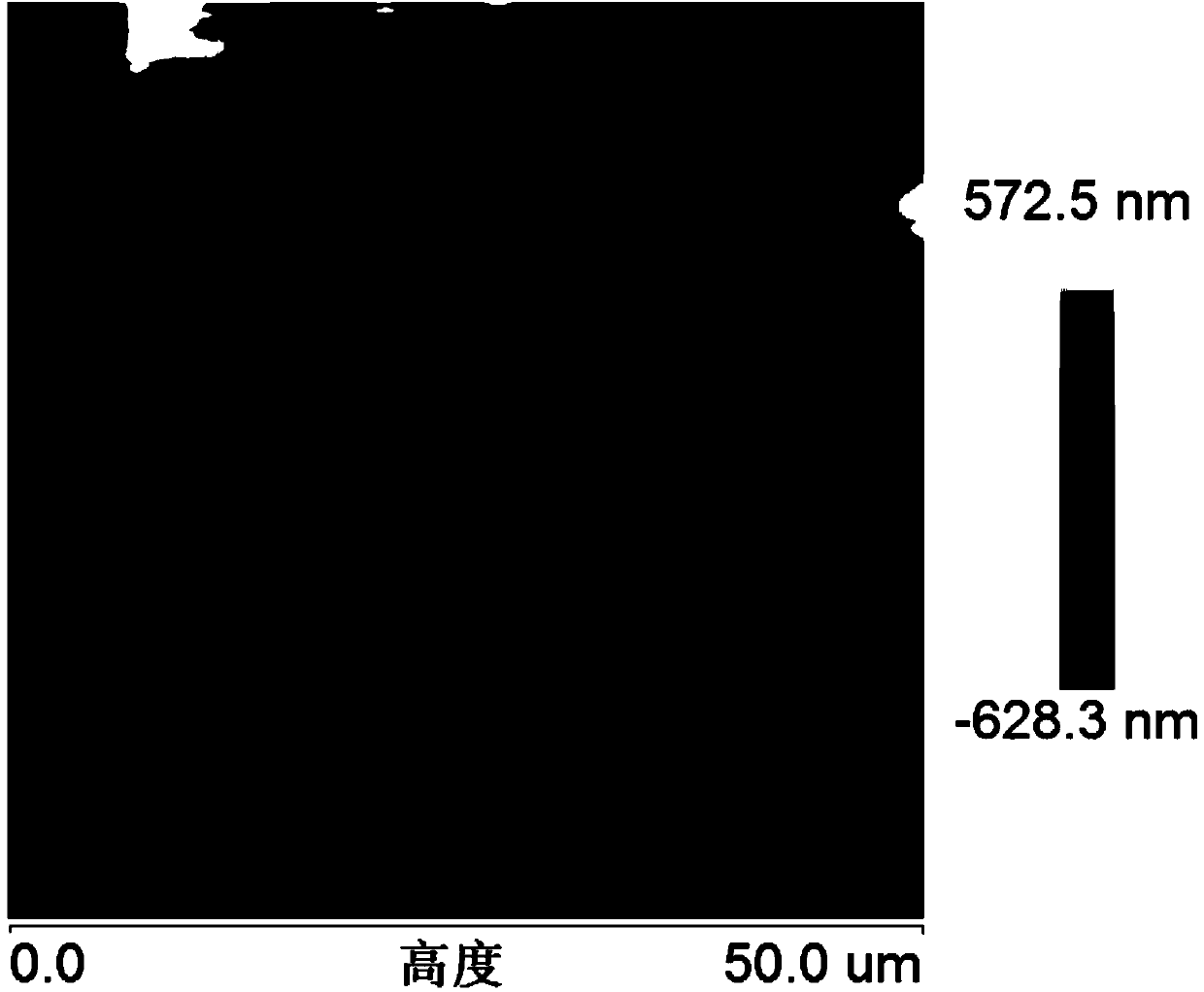

[0043] Preparation of (111)Pt / TiO 2 / SiO 2 Triglycine sulfate (hereinafter referred to as TGS) ferroelectric film with a thickness of 1.0um on a Si substrate:

[0044] (1): Preparation of TGS solution and (111)Pt / TiO 2 / SiO 2 / Si substrate cleaning. Using deionized water as a solvent, prepare a saturated solution of TGS and a solution with a mass concentration of TGS of 0.1 g / L. The whole process of preparing the solution was carried out at a constant temperature of 24°C. Cut (111)Pt / TiO with a size of 10mm×10mm 2 / SiO 2 / Si substrate, placed in deionized water, ultrasonically cleaned for 15 minutes, placed in absolute ethanol, ultrasonically cleaned for 15 minutes, and dried with N 2 Air dry.

[0045] (2): Spin-coating on (111)Pt / TiO 2 / SiO 2 A uniform TGS thin film layer for crystal growth was prepared on the / Si substrate. Place (111)Pt / TiO 2 / SiO 2 The / Si substrate is placed in the center of the turntable of the spin coater, and the dispensing time of the spi...

example 2

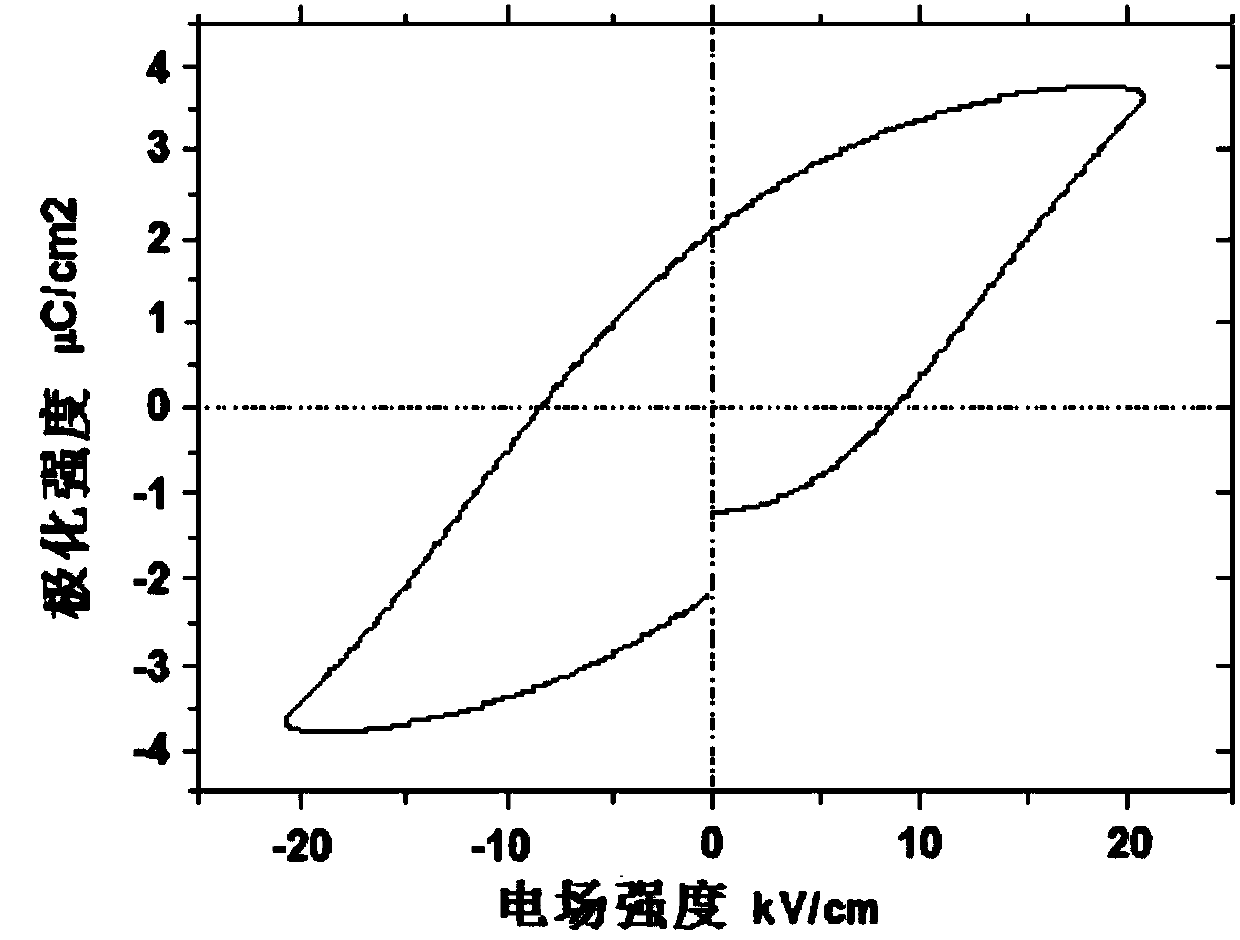

[0050] In (111)Pt / TiO 2 / SiO 2 Diisopropylamine bromide (hereinafter referred to as DIPAB) ferroelectric thin film with a thickness of 500nm was prepared on Si substrate.

[0051] (1): Preparation of DIPAB solution and (111)Pt / TiO 2 / SiO 2 / Si substrate cleaning. Prepare a saturated solution of DIPAB with analytically pure ethanol as a solvent. The whole process of preparing the solution was carried out at a constant temperature of 10°C. Cut (111)Pt / TiO with a size of 20mm×20mm 2 / SiO 2 / Si substrate, placed in deionized water, ultrasonically cleaned for 15 minutes, placed in absolute ethanol, ultrasonically cleaned for 15 minutes, and dried with N 2 Air dry.

[0052] (2): A uniform DIPAB film layer for crystal growth was prepared by dipping-pulling method. Set (111)Pt / TiO 2 / SiO 2 / Si substrate in the saturated DIPAB solution prepared in step (1), after soaking for 5 minutes, select the parameters of the dipping-pulling machine as the pulling rate is 0.01mm / min, an...

example 3

[0056] Preparation of imidazole perchlorate C with a thickness of 300 nm on a PET-ITO substrate 3 N 2 h 5 ClO 4 (hereinafter referred to as Im) ferroelectric thin film.

[0057] (1): Preparation of Im solution and cleaning of PET-ITO substrate. Using analytically pure acetone as a solvent, prepare Im saturated solution, and slowly add deionized water to Im saturated solution until its mass concentration is 90% of the saturated state. Another container preparation Im mass concentration is the solution of 50g / L. The whole process of preparing the solution was carried out at 0°C. Cut a PET-ITO substrate with a size of 30mm×30mm, put it in deionized water, and ultrasonically clean it for 15 minutes, put it in absolute ethanol, and ultrasonically clean it for 15 minutes, and dry it with N 2 Air dry.

[0058] (2): A uniform Im film layer for crystal growth was prepared on a PET-ITO substrate by a spin coating method. Put the PET-ITO substrate in the center of the turntable o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com