Multi-stage gas distribution high-temperature coal gasification device and method

A coal gasification, high temperature technology, applied in the gasification of granular/powdered fuel, the manufacture of combustible gas, the petroleum industry, etc., can solve problems such as low pollution, achieve less fly ash, avoid combustion, and improve the effect of carbon conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

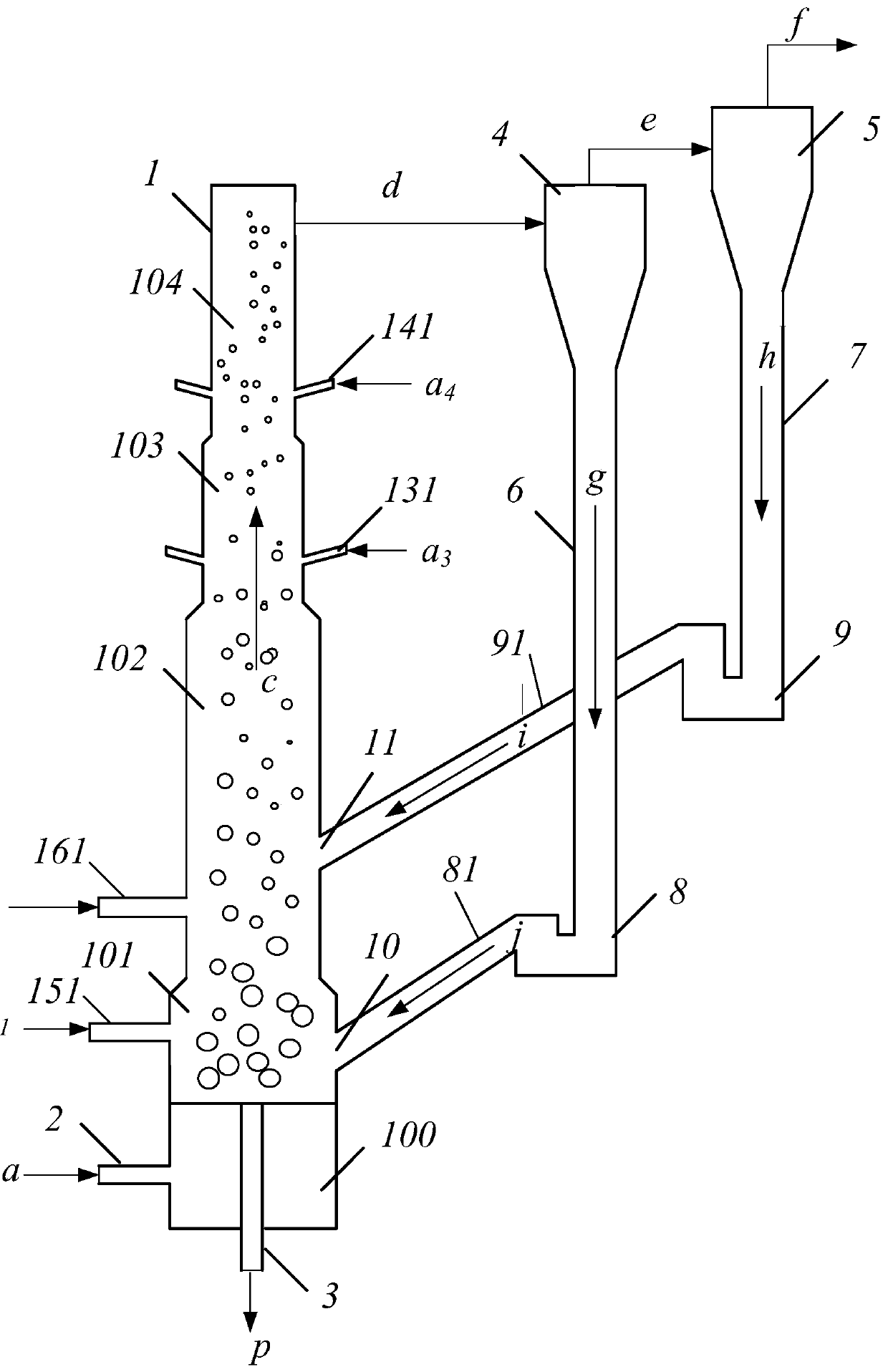

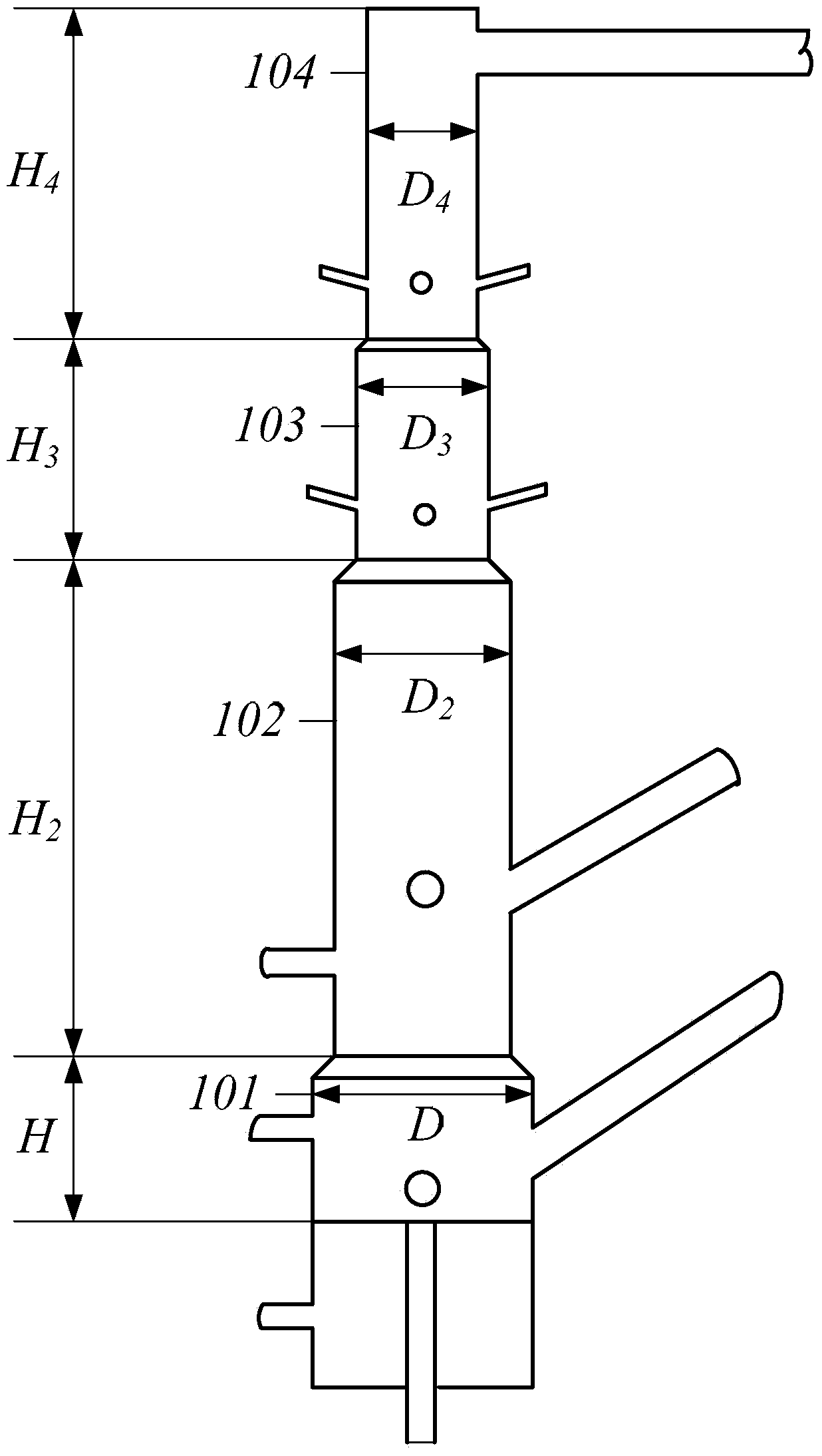

[0038] Such as figure 1 , figure 2 Shown is a multi-stage gas distribution high-temperature coal gasification device, including a gasification reactor 1 and an air chamber 100. The air chamber 100 is arranged at the bottom of the gasification reactor 1, and the gasification reactor 1 is divided from bottom to top. The oxygen-enriched combustion section 101, the mixed gasification section 102, the gasification heating section 103 and the gasification lifting section 104; The gasification heating section 103, the gasification heating section 103 shrinks upwards and transitions to the gasification lifting section 104;

[0039] The air chamber 100 is provided with an air chamber gasification agent inlet 2 and an air chamber slag discharge pipe 3;

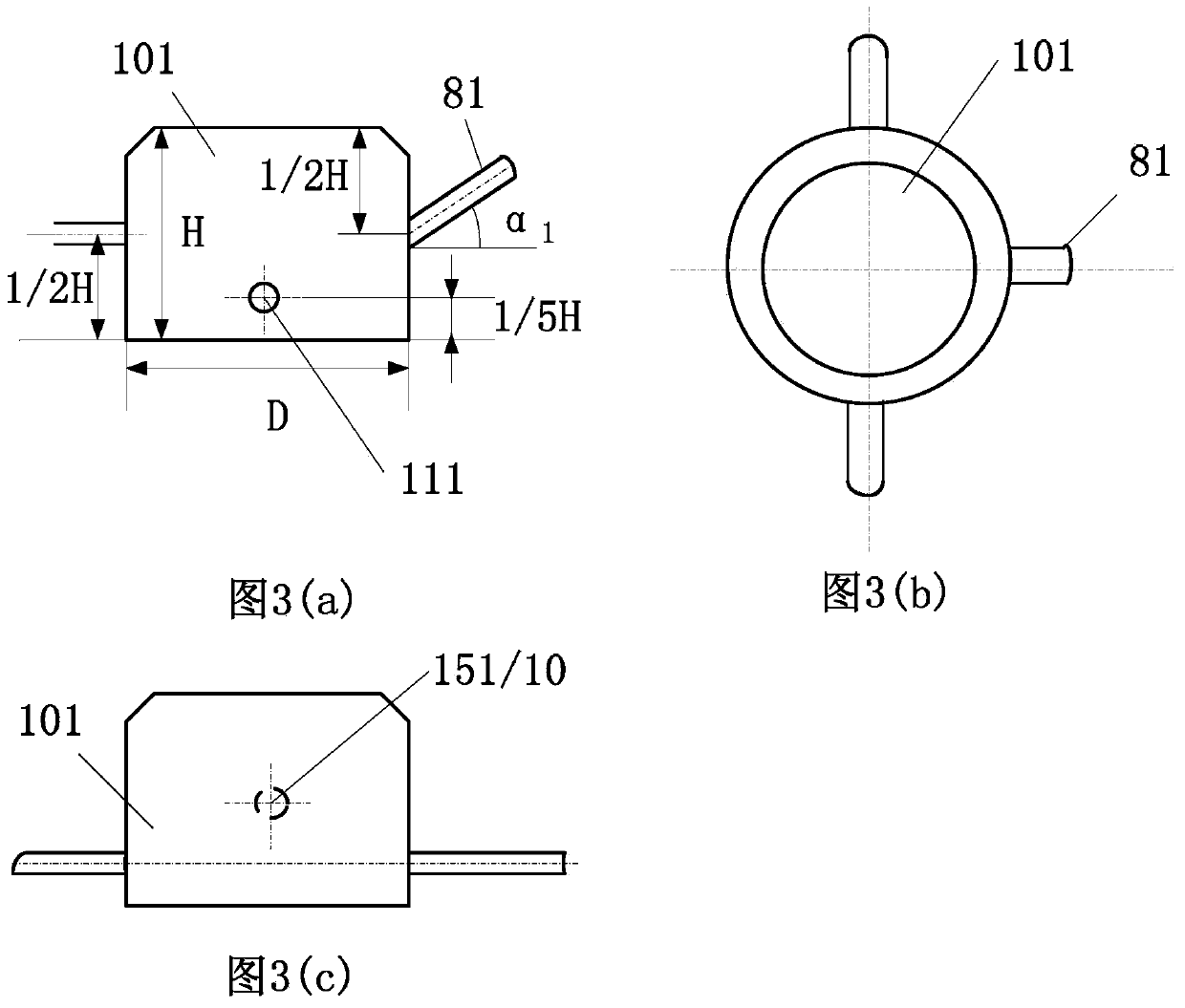

[0040] The lower side of the oxygen-enriched combustion section 101 is provided with a primary feed port 151, a primary re...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap