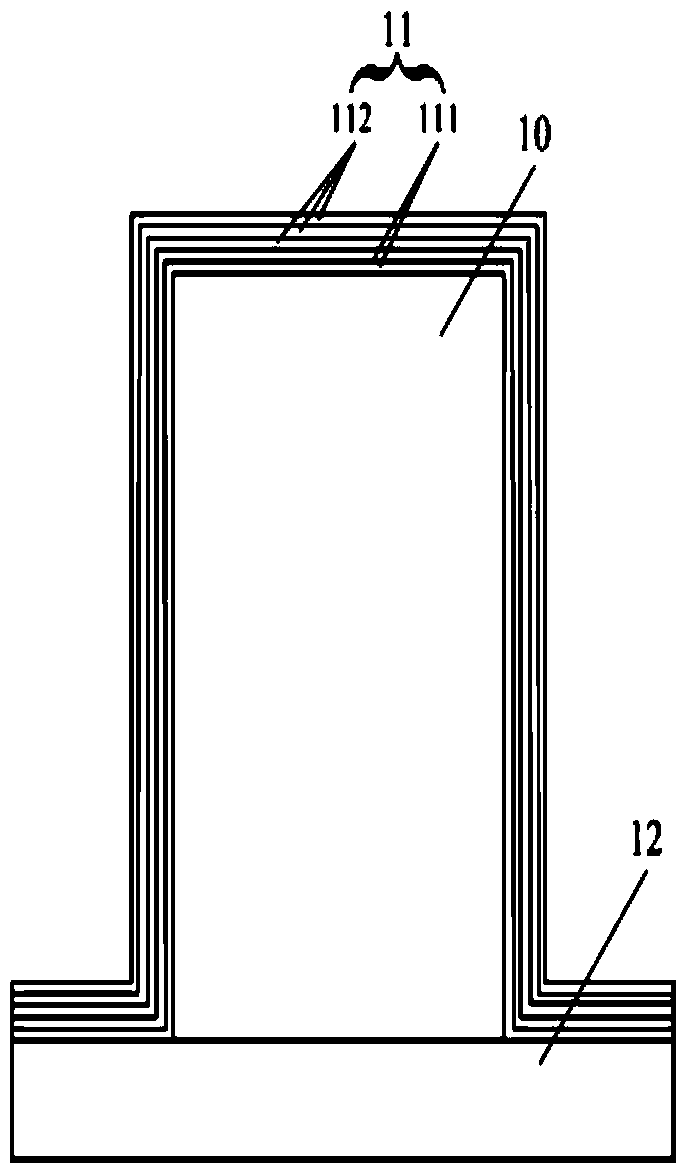

Heavy excavation anti-corrosion foundation for ultrahigh voltage transmission line in salty soil region and preparation method

A transmission line and ultra-high voltage technology is applied to the anti-corrosion foundation of large excavation of transmission lines and towers and its preparation field, and can solve the problems of low alkalinity, easy erosion, and short effective service life of asphalt coatings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] The technical scheme of the present invention has been successfully applied in the Hami South-Zhengzhou ±800kV UHV DC transmission line project that has been completed and put into production. Taking the 1670# foundation of the 8th bid section of the project as an example, the specific embodiments are briefly described as follows:

[0086] The 1670# foundation is located in the saline soil area of the Hexi Corridor in Gansu. According to the judgment standard of "Code for Geotechnical Engineering Investigation (2009 Edition)" (GB50021-2001), the foundation soil of the foundation has strong corrosion to the foundation concrete, and the foundation needs to be Carry out anti-corrosion treatment to improve the durability of the foundation and reach the designed service life.

[0087] 1. The strength grade and mix ratio of the foundation concrete. Execute with reference to the table below:

[0088]

[0089] Note: a. C35~C40 can use 5~31.5mm crushed stones, and C50 must...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com