Composite board curtain wall board

A technology of composite panels and curtain wall panels, which is applied to walls, building components, buildings, etc., can solve the problems of the application of metal curtain wall panels without using titanium metal composite panels, the thickness of titanium steel composite panels is large, and it is uneconomical, and achieves structural stability. Guaranteed, low price, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

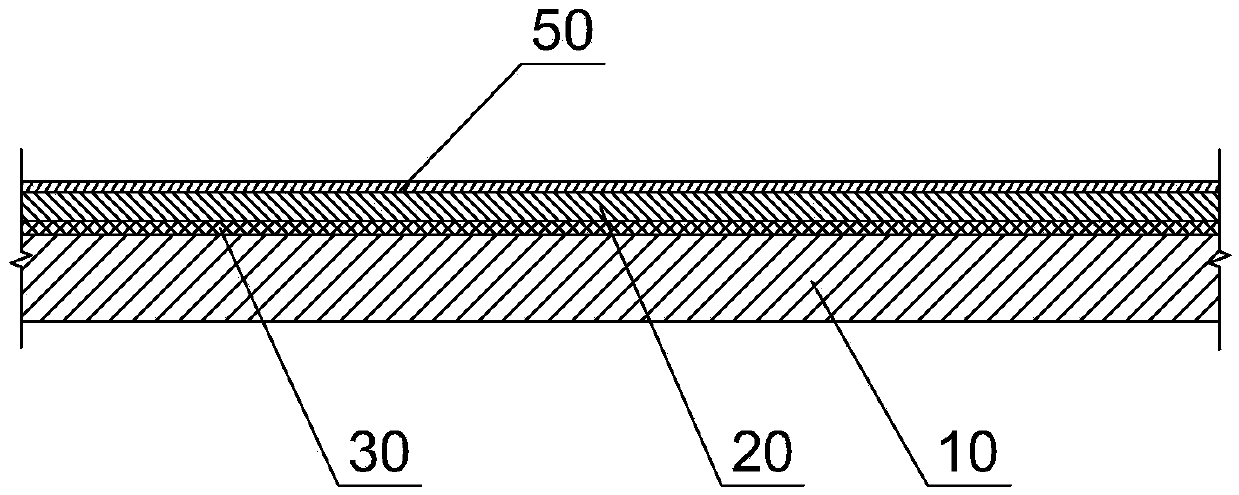

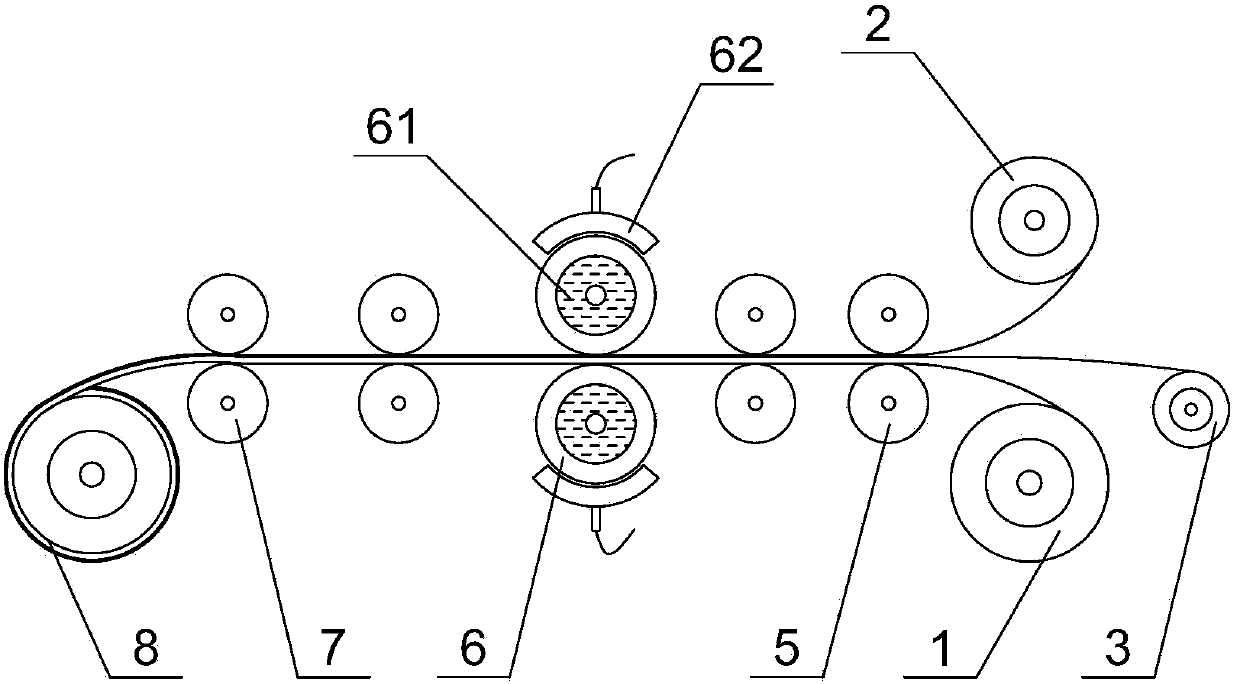

[0034] Such as figure 1 , Figure 7 As shown, the composite panel curtain wall panel of this embodiment is made of titanium and metal composite panels, specifically, a titanium-aluminum double-layer composite panel. The plate structure of the composite panel curtain wall panel includes a square bottom substrate 41, two adjacent sides of the bottom substrate 41 are provided with a first hanging edge 42, and the other two adjacent sides are provided with a second hanging edge 43, The first hanging edge 42 and the second hanging edge 43 are respectively bent towards two different bottom surfaces of the bottom substrate 41 , and the first hanging edge 42 is passed between two adjacent enclosure panels. It is suitable for hooking with the second hanging edge 43 . The cross-sectional structure of the composite sheet curtain wall panel includes a metal substrate base layer 10, a titanium composite layer 20, and a solder layer 30, and the titanium composite layer 20 is compounded on...

Embodiment 2

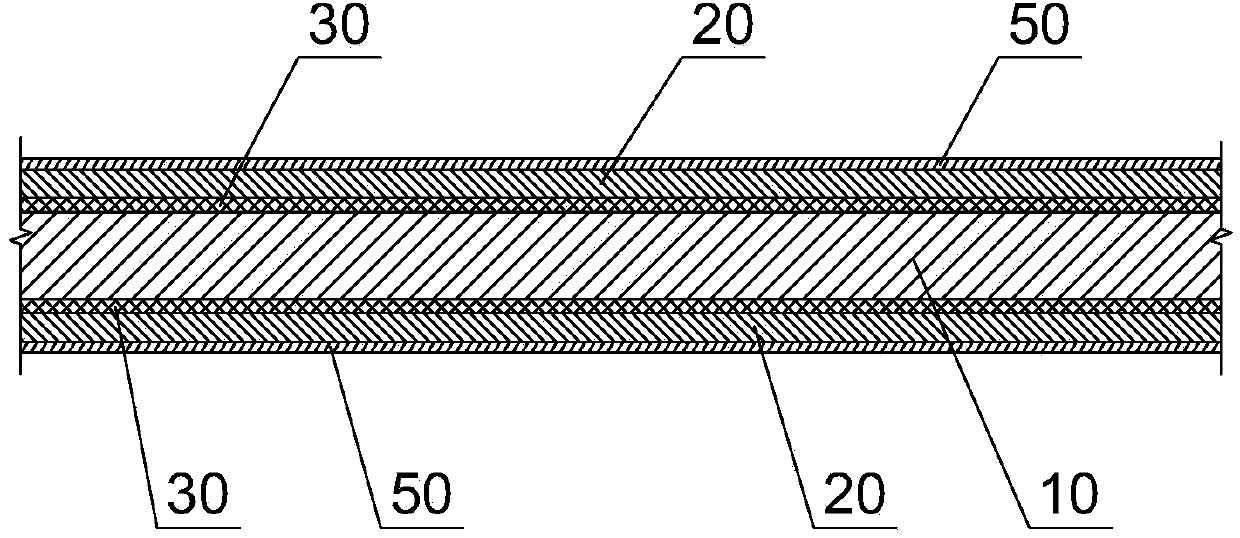

[0043] Such as image 3 , Figure 7 As shown, the composite panel curtain wall panel of this embodiment is made of a double-layer titanium single-layer steel composite panel. The panel structure of the composite panel curtain wall panel is the same as that of the first embodiment, and its cross-sectional structure includes a metal base plate layer 10, Titanium composite layer 20, solder layer 30, the titanium composite layer 20 is composited on both sides of the metal substrate base layer 10, the solder layer 30 is located between the metal substrate base layer 10 and the titanium Between the composite layers 20, the metal substrate base layer 10, the solder layer 30 and the titanium composite layer 20 are tightly composited into one body through hot rolling, and the interfaces between the layers achieve metallurgical bonding. In the embodiment, the material of the metal substrate floor layer 10 is ordinary steel, such as ordinary structural steel, the brazing filler metal la...

Embodiment 3

[0054] Such as Figure 5 , Figure 7 As shown, the composite panel curtain wall panel of this embodiment is made of titanium and weathering steel composite panel, the panel structure of the composite panel curtain wall panel is the same as that of Example 1, and its cross-sectional structure includes a metal base plate layer 10, a titanium composite layer 20. The titanium composite layer 20 is composited on a single surface of the metal substrate bottom layer 10, the exposed surface of the metal substrate bottom layer 10 is the metal substrate oxide layer 40, and the titanium composite layer 20 The exposed surface is an oxide layer 50 of titanium, and the titanium composite layer 20 and the metal substrate bottom layer 10 are combined into one body by hot pressing, and the composite between the titanium composite layer 20 and the metal substrate bottom layer 10 The interface is a molecular metallurgical combination, the surface of the titanium oxide layer 50 is transparent, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com