A low-noise triaxial radio frequency multifunctional tensile cable

A three-axis radio frequency, low-noise technology, applied in the direction of insulated cables, communication cables, cables, etc., can solve the problems of measurement error, inaccurate measurement, bad noise, etc., to achieve simple process, meet the requirements of shielding performance, and save products cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

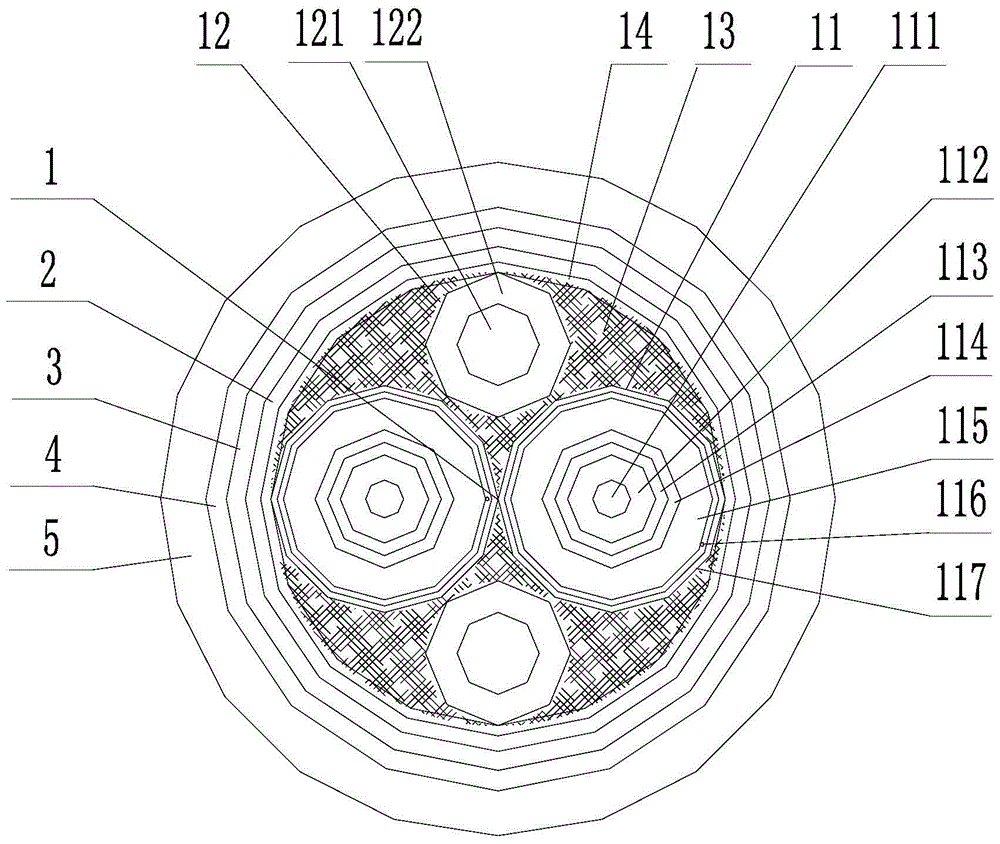

[0027] As shown in the accompanying drawings, a low-noise triaxial radio frequency multifunctional tensile cable is composed of a central layer 1, a braided layer 2, a middle layer 3, a total shielding layer 4 and an outer layer 5 from the inside to the outside; The central layer 1 includes more than two low-noise radio frequency wires 11 and more than two power cords 12, the gap between the low-noise radio frequency wires 11 and the power cord 12 is provided with a glass fiber filling rope 13, and the filling rope 13 is wrapped with a polyester tape 14. The low-noise radio frequency line 11 includes a conductor 111 twisted from a plurality of thin tinned copper wires from the inside to the outside, and the conductor 111 is bonded with a cross-linked polyethylene insulating paint film, that is, the first insulating layer of cross-linked polyethylene 112, the first insulating layer 112 is coated with a low-noise conductive layer 113, the low-noise conductive layer 113 is braided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com