Floating type multifunctional hydrant for farmland pipeline irrigation

A water supply plug and multi-functional technology, applied in the field of agricultural irrigation, can solve the problems of easy imitation of the open wrench, complex structure, insufficient exhaust volume, etc., and achieve the effect of convenient and fast combined installation, high cost performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

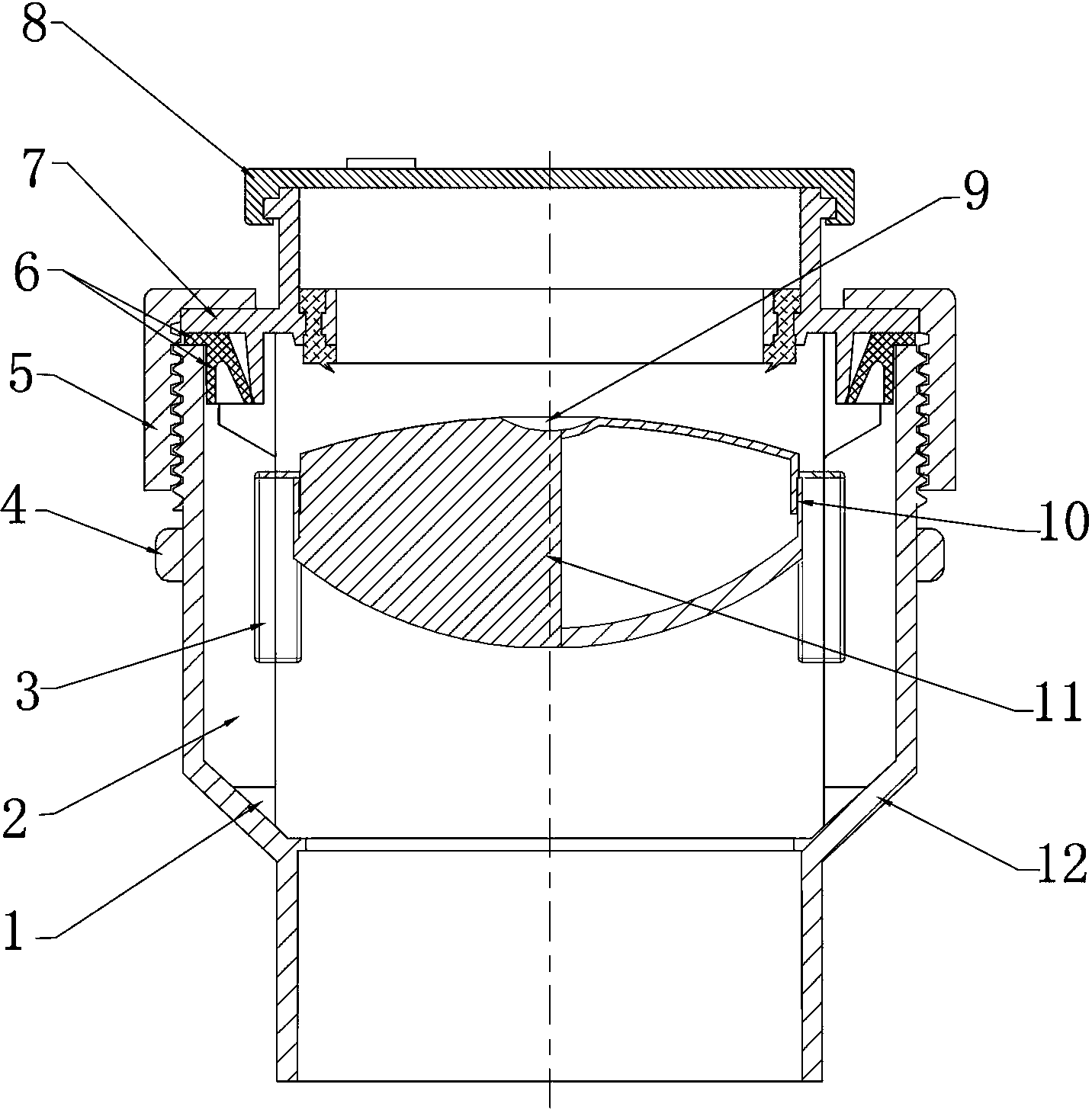

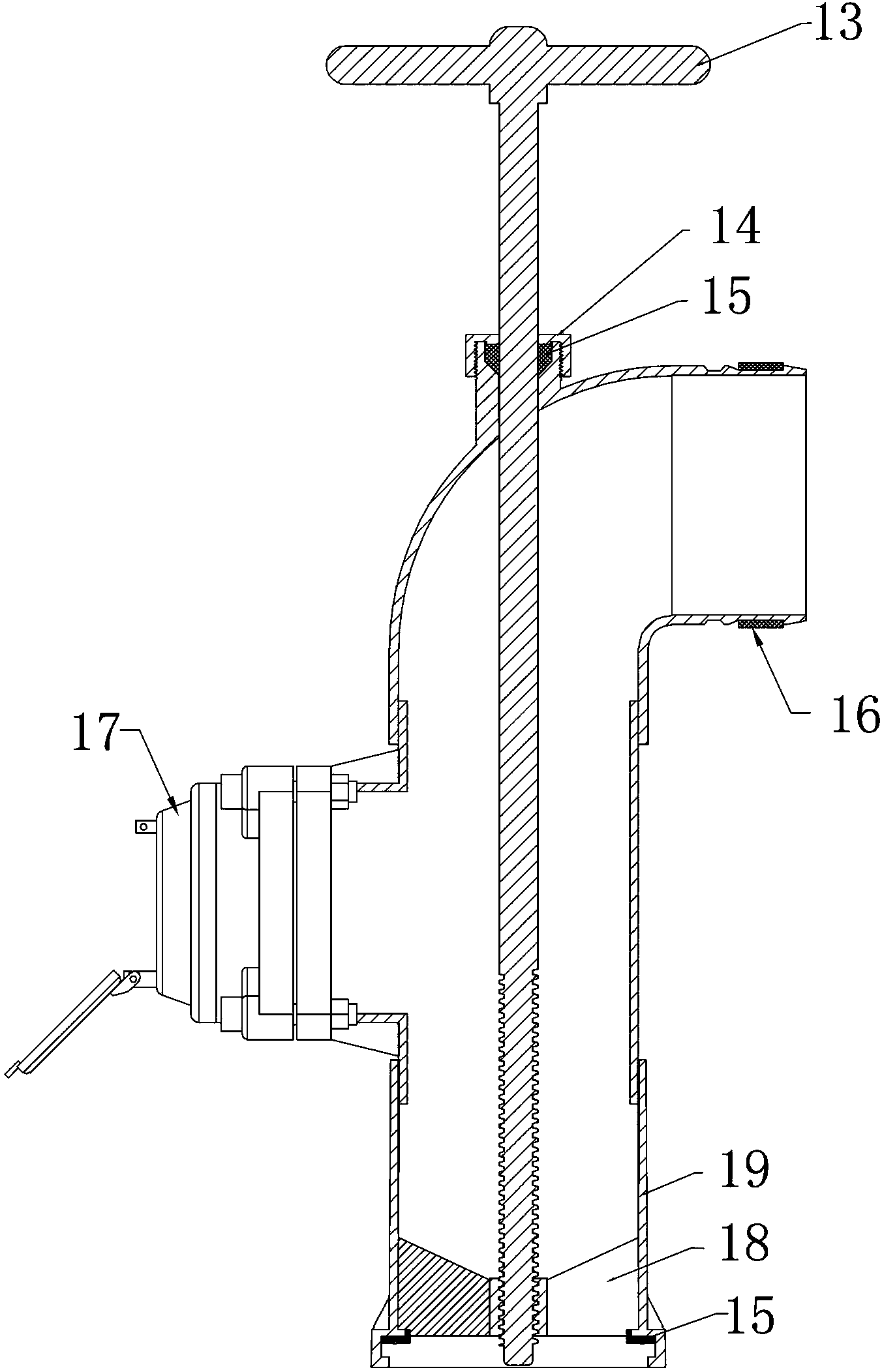

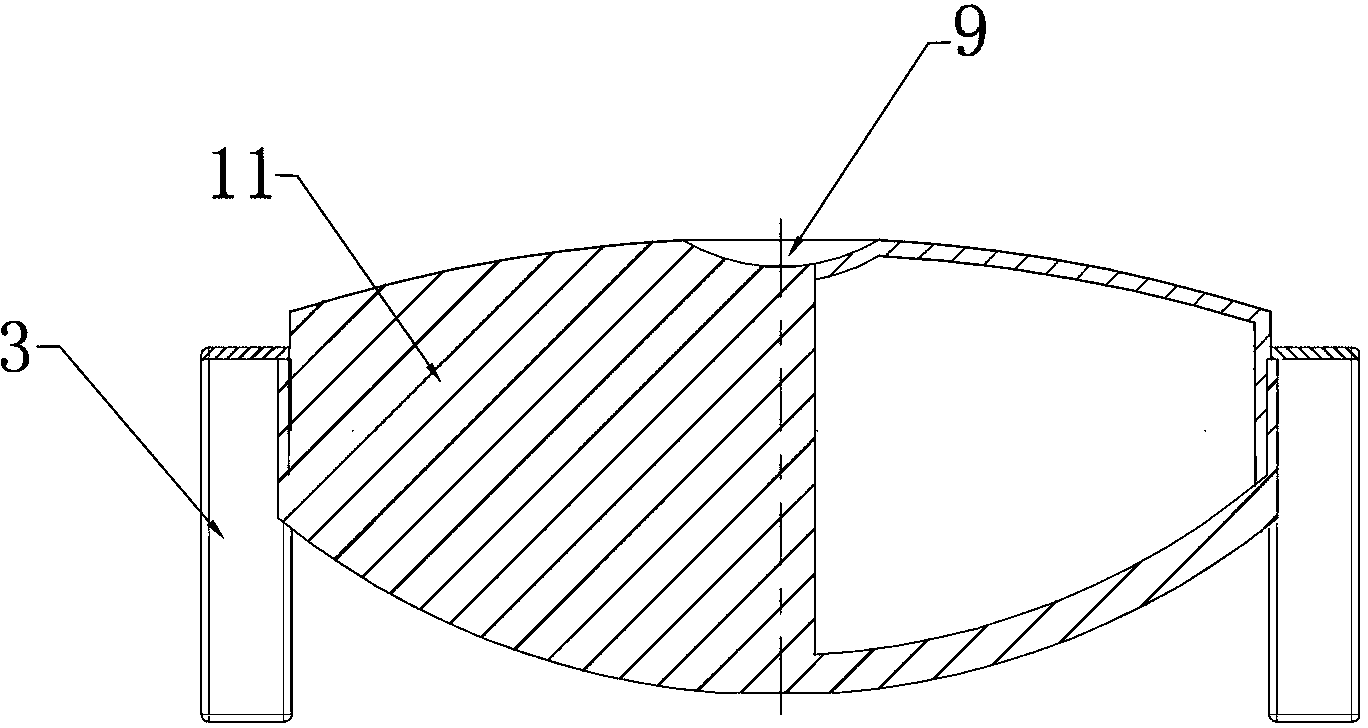

[0038] As shown in the figure: the water supply plug adopts a semi-fixed split combination structure, the lower plug body 12 is fixed below the ground, a floating body type water stop valve 10 is installed inside the lower plug body 12, and the lower plug body 12 is placed in the concrete protection pipe. It is connected with the three-way standpipe of the pipeline to form a fixed device for water supply to the field; the lower plug body 12 adopts the principle of floating body water stop, which realizes the functions of air intake, exhaust, and automatic closing; the upper plug body cooperates with the lower plug body, and the upper plug body The bottom of the body is provided with a cross support rib 18 and an unlatching drive nut 23, forming a special tool for pushing the floating body downward and opening the lower bolt body.

[0039] The lower bolt body is composed of a lower shell, a connecting wire cap, a quick connector, a slideway, a water-stop rubber ring, a floating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com