Method for preparing uranium adsorbent and curing agent from white mud and oil shale ash

The technology of oil shale ash and curing agent is applied in the field of uranium adsorption and curing material preparation, which can solve the problems of narrow application range, single product type of uranium-containing wastewater treatment materials, and high production cost, so as to improve the treatment capacity and improve the uranium-containing wastewater. Wastewater treatment capacity, the effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

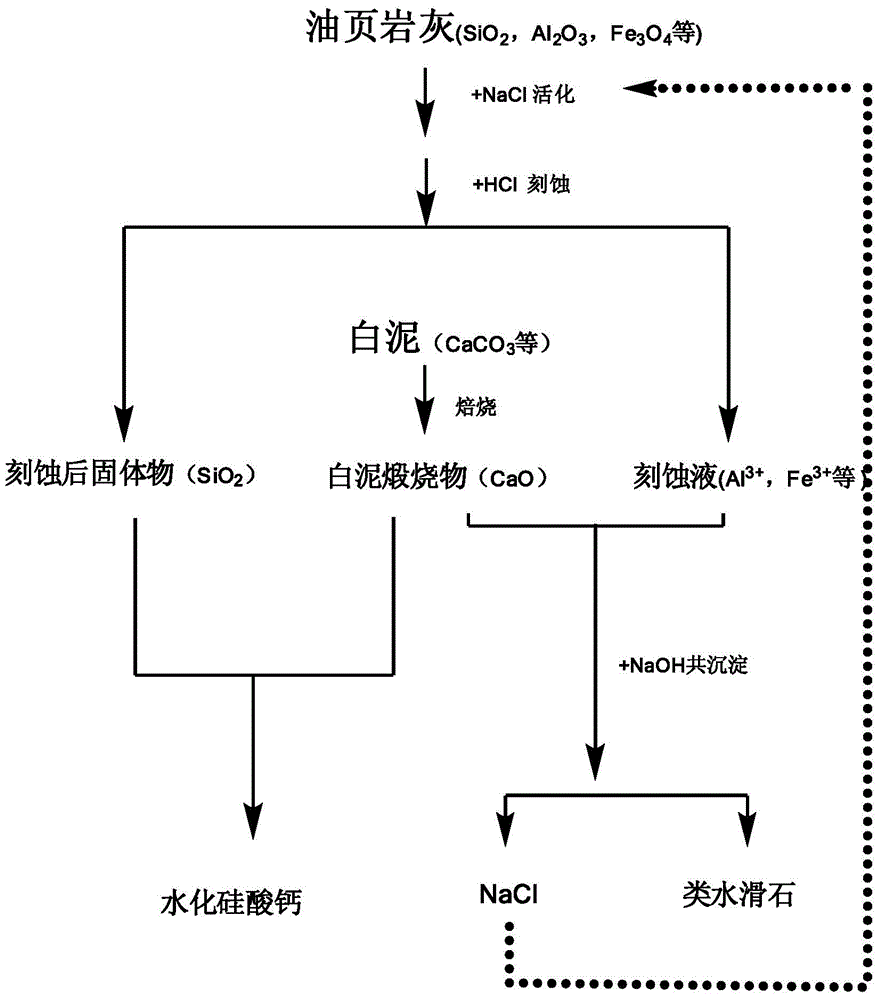

Method used

Image

Examples

Embodiment 1

[0036] (1) Crush and grind the oil shale ash to 200 mesh, add NaCl with 40-100% of the ash mass, calcinate at 1000-1200K for 3-10 hours, and air-dry to obtain sample A.

[0037] (2) According to the ratio of 2-5mL per gram of A, add 2-8M HCl to A. Extract metal ions under 333-573K vigorous stirring or microwave-assisted conditions, extract for 3-10 hours, separate the extract from the residue, grind and pulverize the residue. Repeat this step 3-10 times, and combine the extracts to obtain sample B. The final residue is 40-60%H 2 SO 4 Washed under vigorous stirring at 353-393K to obtain sample C

[0038] (3) Calcining the white mud 1173-1273K for 3-10 hours, the CO produced during the calcination process 2 Recovery with NaOH, preparation of Na 2 CO 3 . The product of calcined lime mud is sample D, and the CO 2 Save under conditions.

[0039] (4) By adjusting the method of adding the mass of D to B, the ratio of the total moles of trivalent and tetravalent metal ions to...

Embodiment 2

[0043] Change (1) in Example 1 to: crush and grind the oil shale ash to 200 mesh, add NaCl with 60-100% of the ash mass, calcinate at 1100-1200K for 3-8 hours, and air-dry to obtain sample A .

Embodiment 3

[0045] Change (1) in Example 2 to: crush and grind oil shale ash to 200 mesh, add NaCl with 80-100% ash mass, calcinate at 1150-1200K for 3-5 hours, and air-dry to obtain sample A .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com