System and method for preparing high value-added products by catalytic pyrolysis of municipal sludge

A catalytic pyrolysis, high value-added technology, applied in the field of solid waste resource treatment, can solve the problems of poor product quality, limited application scope and fields, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

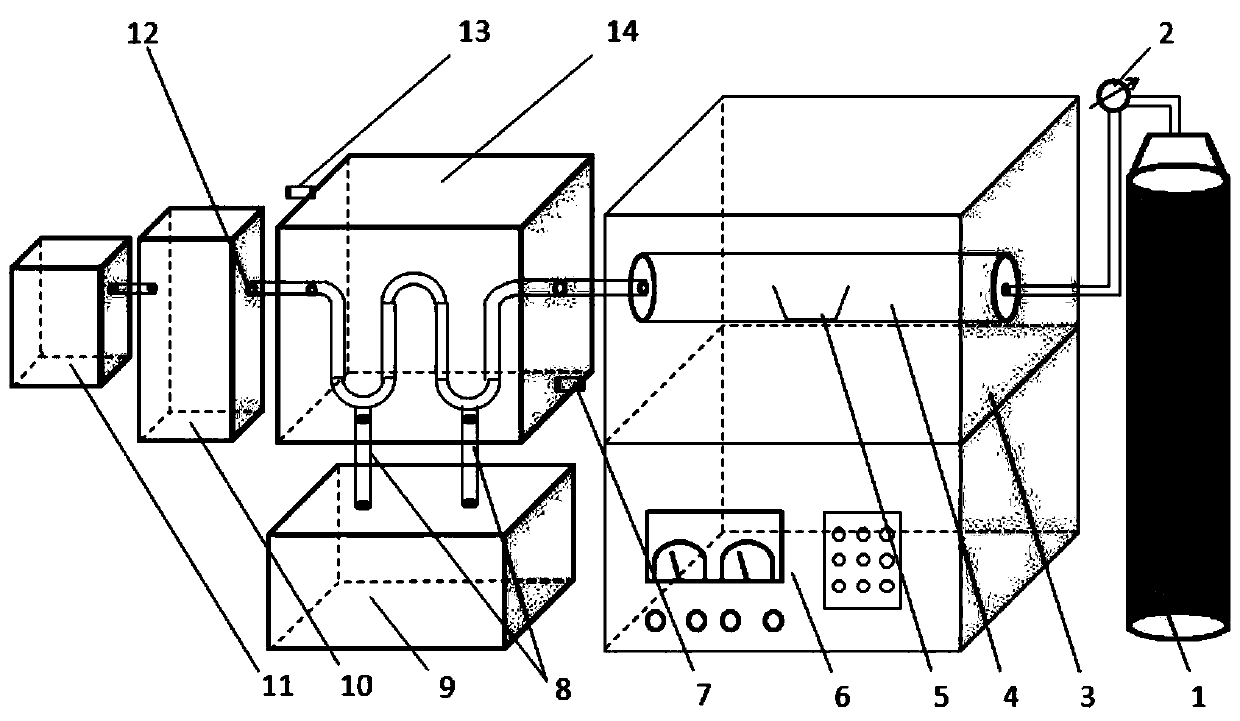

[0031] combine figure 2 , a system for producing high value-added products by catalytic pyrolysis of municipal sludge is described in detail. A system for producing high value-added products by catalytic pyrolysis of municipal sludge includes:

[0032] Pyrolysis furnace 3, a quartz tube 4 is provided in the pyrolysis furnace 3; a nitrogen inlet is provided at the first end of the quartz tube 4, and a pyrolysis product outlet is provided at the second end; a porcelain boat is placed in the quartz tube 4 5; There is a control panel 6 on the pyrolysis furnace.

[0033] A condensing device 14, the condensing device 14 has a pyrolysis product inlet, a pyrolysis gas outlet, and a pyrolysis oil outlet; the pyrolysis product inlet is connected to the second end of the quartz tube; the condensing device 14 is a partition water cooling device, The condensed water inlet pipe 7 is provided below the condensing device 14, and the condensed water outlet pipe 13 is provided above; the cond...

Embodiment 2

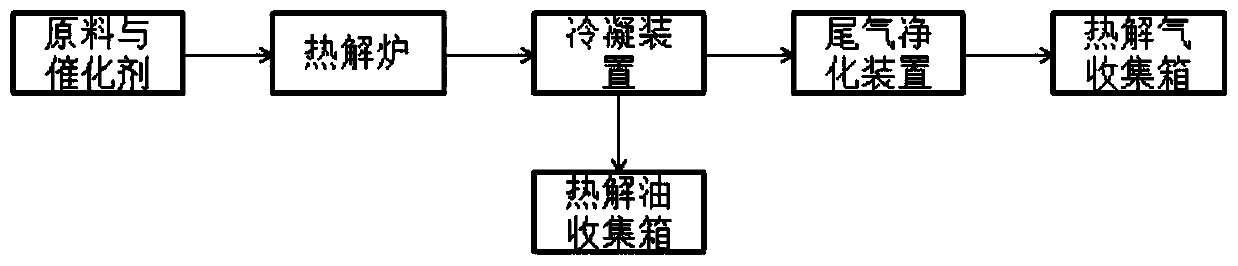

[0039] combine figure 1 with figure 2 , a method for producing high value-added products by catalytic pyrolysis of municipal sludge is described in detail, the method includes the following steps:

[0040] S1: Mix the sludge raw material with a water content of 50% and the catalyst evenly, place it in the quartz tube of the pyrolysis furnace, and carry out pyrolysis under the protection of nitrogen gas to obtain pyrolysis products; the pyrolysis products are gas and liquid Pyrolysis gas, pyrolysis oil, and pyrolysis carbon in a solid mixed state; the catalyst is one or more of calcium hydroxide, calcium carbonate, zinc chloride, calcium chloride, calcium oxide, zinc oxide, and superphosphate ; The mass ratio of the catalyst to the sludge raw material on a dry basis is 1:20-1:40.

[0041] S2: Pass the pyrolysis products including pyrolysis gas and pyrolysis oil into the pipeline to the condensing device, and separate the liquid product pyrolysis oil;

[0042] S3: The pyroly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com