Pipe end reserved treatment method for steel pipe anti-corrosion outer coating

A treatment method and outer coating technology, applied in the direction of pipeline anti-corrosion / anti-rust protection, coating, pipe / pipe joint / pipe fitting, etc., can solve the problems of insufficient removal, high energy consumption, low operation efficiency, etc. Complete, zero energy consumption, high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings of the description.

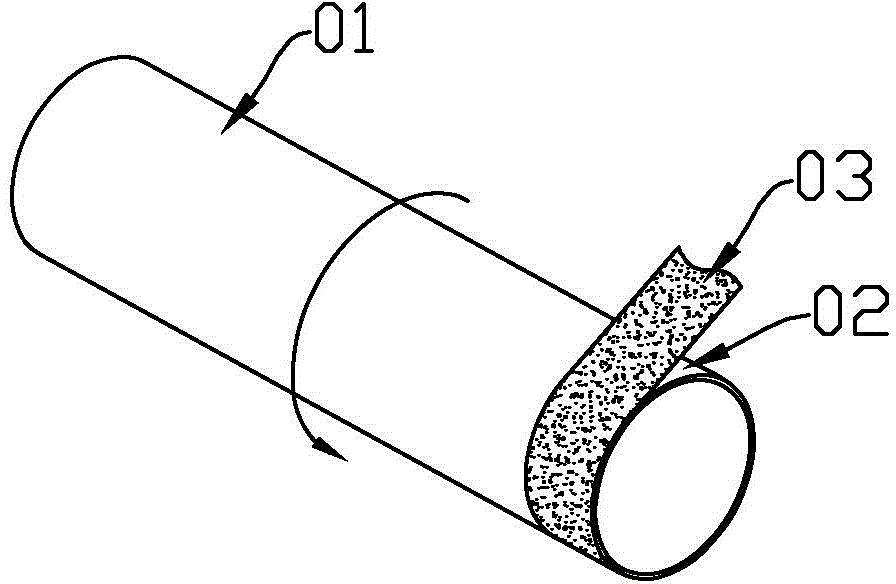

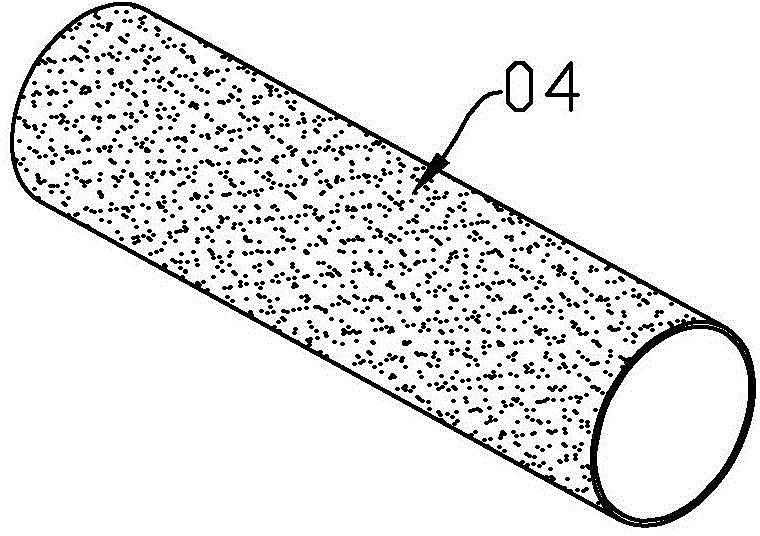

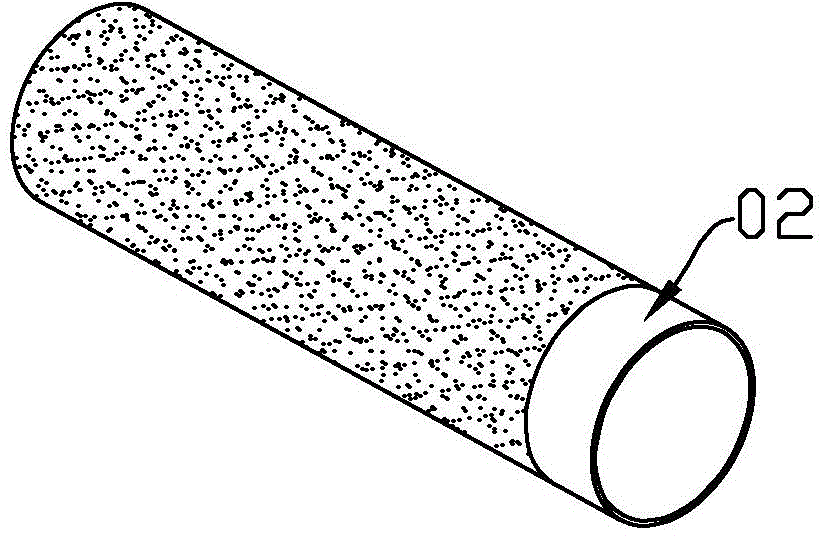

[0015] The steel pipe anti-corrosion outer coating pipe end reservation treatment method of the present invention is to wrap and shield the reserved part 2 at the pipe end of the steel pipe 1 with a shelter 3 (see figure 1 ), and then spray an anti-corrosion outer coating 4 on the steel pipe 1 (see figure 2 ), and finally peel off the cover to expose the reserved part 2 of the steel pipe end (see image 3 ).

[0016] Specifically, the shelter is in the shape of a wide band, the inner end of which is bonded to the reserved part of the steel pipe end, and the remaining part is wound layer by layer and the outer end is bonded and fixed. Especially when the steel tube is turning (see figure 1 The direction of the arrow shown), using the rotation of the steel pipe to wrap the shield around the reserved part of the steel pipe end, the operation is simp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com