Complex oily wastewater treatment method and device

A complex technology for wastewater treatment, applied in flotation water/sewage treatment, adsorbed water/sewage treatment, oxidized water/sewage treatment, etc. It can solve problems such as complex composition, and achieve low oil content in effluent, low manufacturing cost, and operation. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

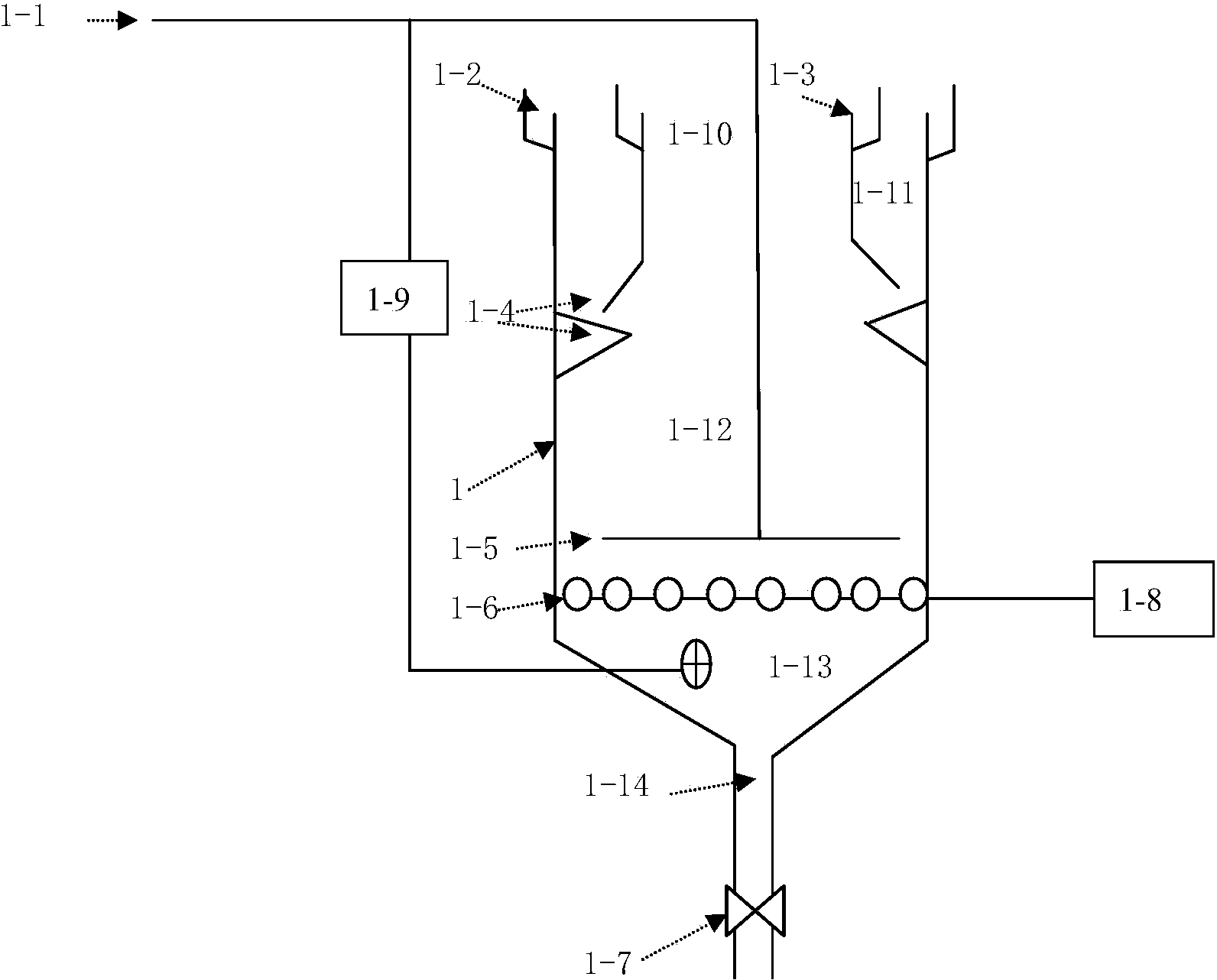

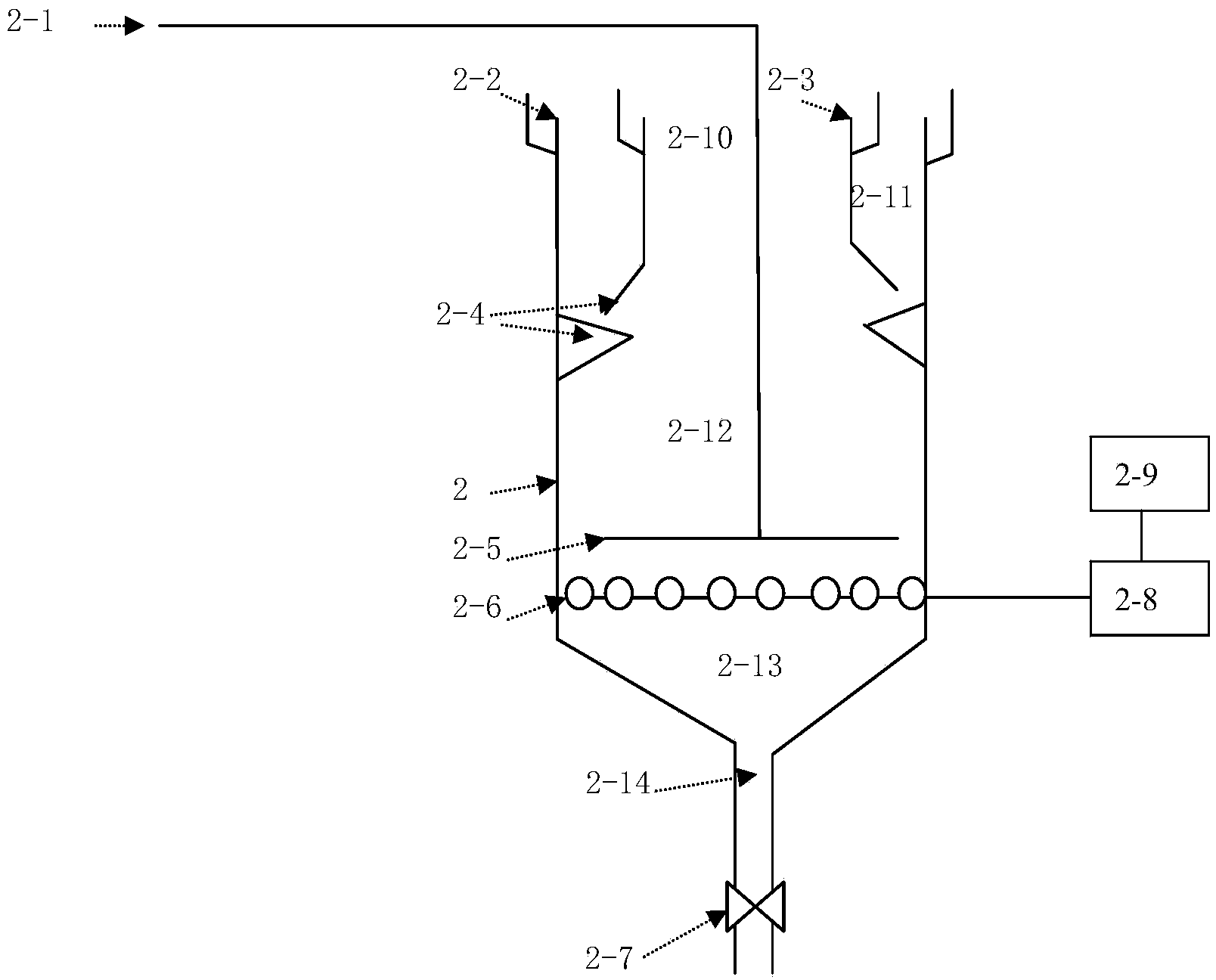

[0039] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

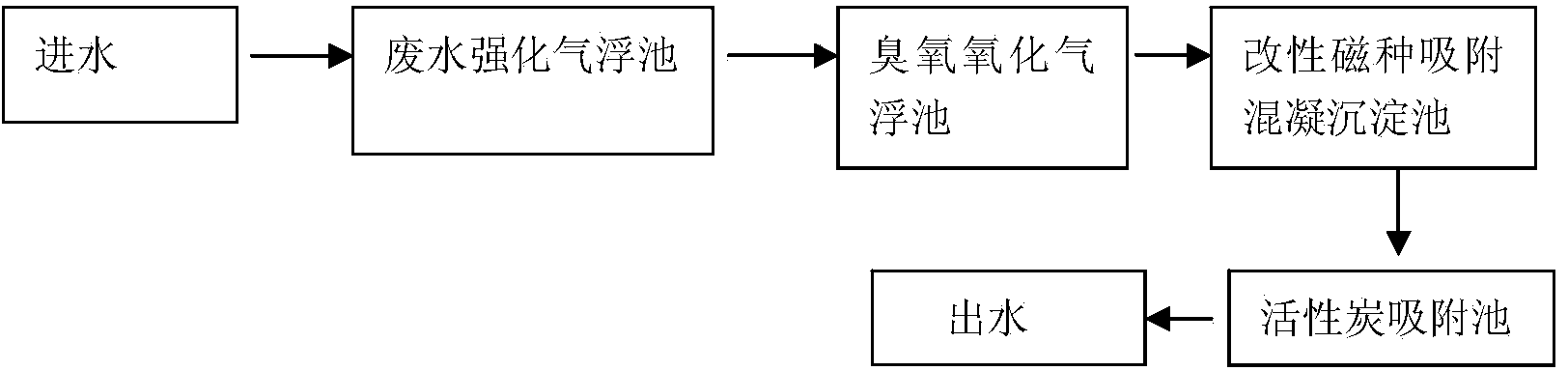

[0040] Such as figure 1 As shown, a complex oily wastewater treatment method and device of the present invention include a wastewater enhanced air flotation tank 1, an ozone oxidation air flotation tank 2, a modified magnetic seed adsorption coagulation sedimentation tank 3, and an activated carbon adsorption tank 4.

[0041] The waste water enhanced air flotation tank 1 includes a water inlet pipe 1-1 and an outlet pipe for discharging treated water. The waste water enhanced air flotation tank 1 is sequentially composed of a sand collection area 1-14 and a sludge area 1-1 from bottom to top. 13. Mixing zone 1-12 and separation zone, said separation zone incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com