Coal gangue activation process adopting synergism of pre-decomposition kiln

A technology for pre-decomposing kiln and coal gangue, which is applied in cement production and other directions, can solve the problems of uncontrollable coal gangue combustion temperature, complicated furnace body and auxiliary building construction, affecting the activity of coal gangue materials, etc. Excellent performance and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

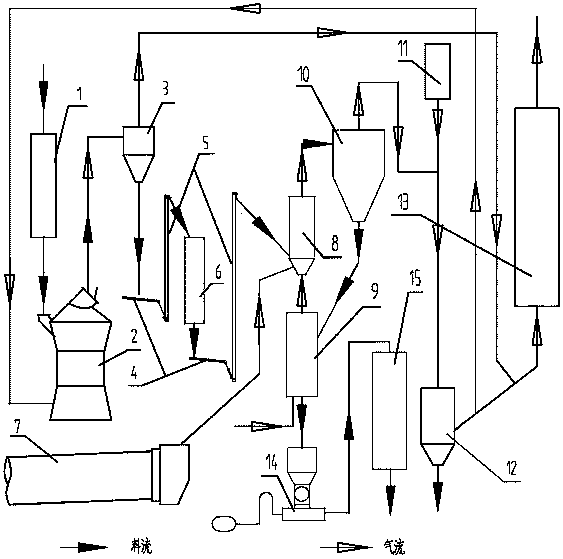

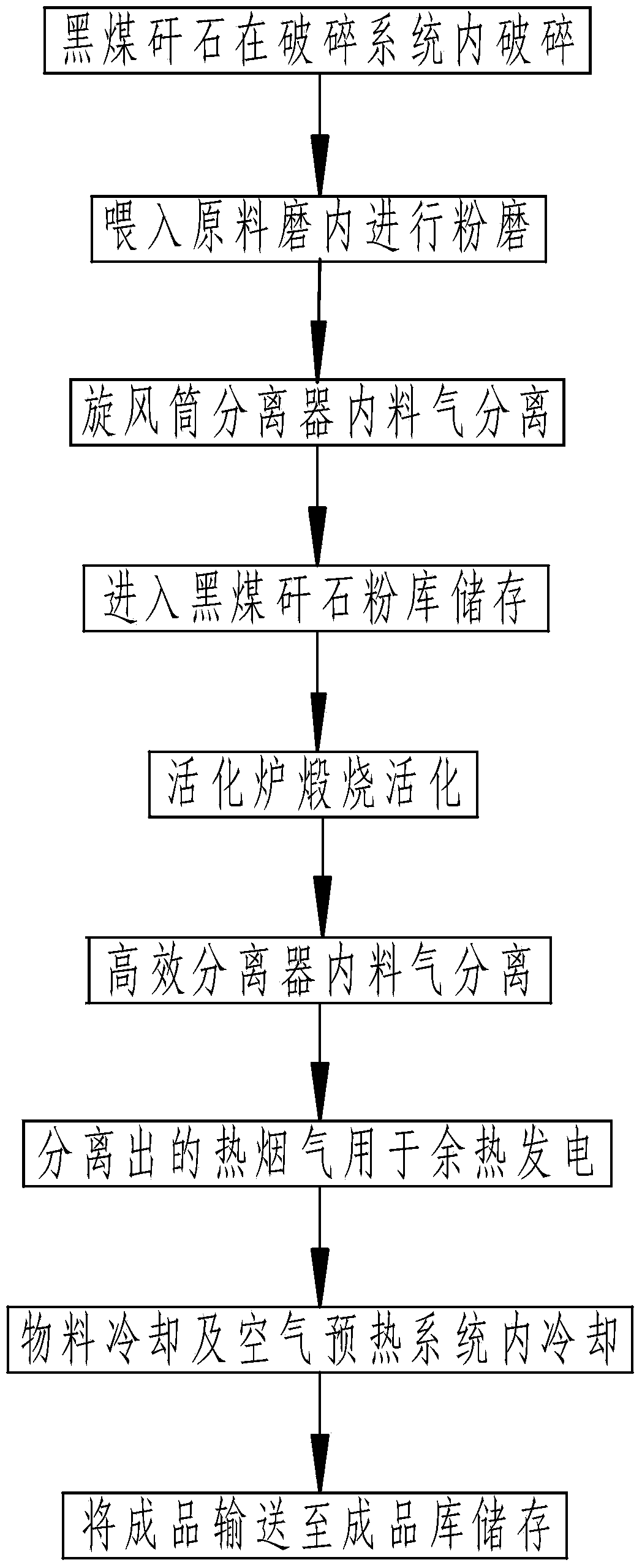

[0031] After the black coal gangue is crushed in the crushing system 1, it is fed into the raw material mill 2 for grinding, and after the material gas is separated by the cyclone separator 3, it enters the black coal gangue powder warehouse 6 for storage, and the black coal gangue powder is fed into the activation furnace 8 for further processing. Calcination activation, black coal gangue powder is activated to become activated coal gangue powder, enters the high-efficiency separator 10 for material gas separation, and the separated hot flue gas is used for waste heat power generation, activated coal gangue powder is in the material cooling and air preheating system 9 After cooling, the finished product is transported to the finished product warehouse 15 for storage.

Embodiment 2

[0033] The black coal gangue is crushed into tiny particles in the crushing system 1, and fed into the raw material mill 2, where it is ground into black coal gangue fine powder with a fineness of 0.08mm square hole sieve and no more than 8% , the finely ground black coal gangue powder is mixed with the airflow from the waste heat boiler 12 and enters the cyclone separator 3 through the outlet of the raw material mill 2, and the separated flue gas enters the dust collection system 13 for treatment and is discharged. The separated black coal gangue powder Through the conveying device 4 and the elevator 5, it is fed into the black coal gangue powder storehouse 6 for storage.

Embodiment 3

[0035] After the black coal gangue powder in the black coal gangue powder storage 6 is measured by the metering device, it is continuously fed into the activation furnace 8 by the conveying device 4 and the hoist 5; Kiln exhaust gas at -1200°C enters the activation furnace 8; the air enters the material cooling and air preheating system 9 and is preheated to 450-550°C before entering the activation furnace 8; in the activation furnace 8, the black coal gangue powder is mixed with the Bottom-up 1050-1200 ℃ kiln exhaust gas and 450-550 ℃ high-temperature hot gas conduct heat exchange, so that the black coal gangue powder is heated rapidly, and the temperature of the black coal gangue powder is controlled by adjusting the air volume and feeding volume. At 850°C, black coal gangue powder rapidly decomposes, decarburizes and dehydrates to form amorphous Al 2 o 3 , SiO 2 , At the same time, a series of physical and chemical processes are activated, and the black coal gangue powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com