Method for preparing nanometer alumina-coated zirconium oxide (8 mol.% Y2O3) composite ceramic powder

A technology of coating zirconia and nano-alumina, which is applied in the field of preparing nano-alumina-coated zirconia composite ceramic powder, which can solve the problems of zirconia grains and growth that cannot be effectively solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

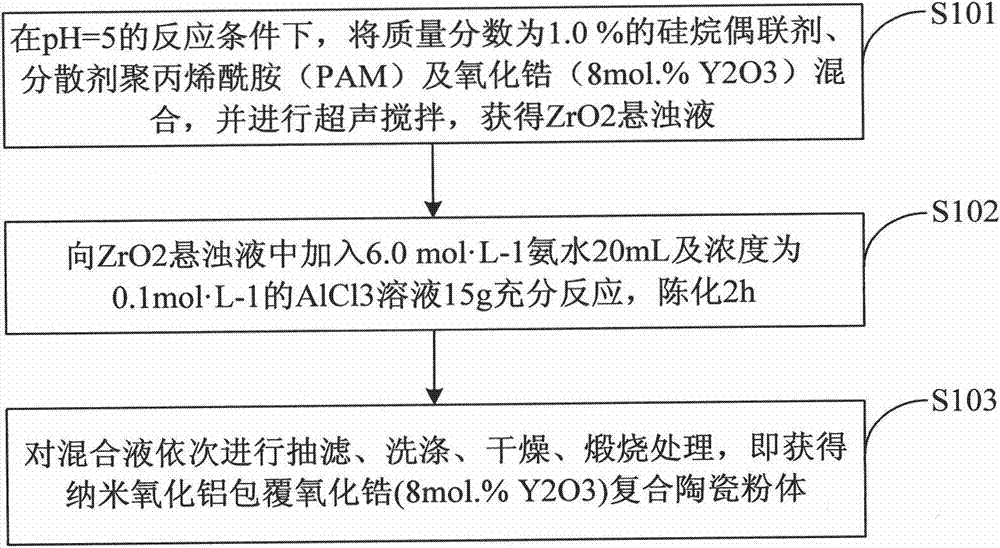

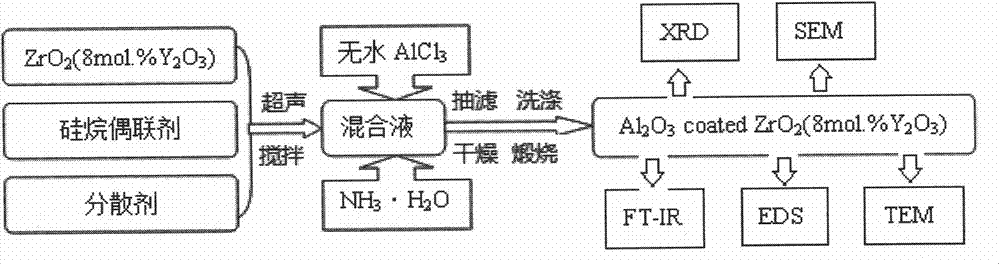

[0022] figure 1 Shows the preparation of nano-alumina coated zirconia (8mol.% Y) provided by the embodiments of the present invention 2 o 3 ) The realization process of the method for composite ceramic powder.

[0023] The object of the present invention is to provide a method for preparing nano-alumina coated zirconia (8mol.% Y 2 o 3 ) method for composite ceramic powder, the method may further comprise the steps:

[0024] Step S101, under the reaction condition of pH=5, the mass fraction is 1.0% silane coupling agent, dispersant polyacrylamide (PAM) and zirconia (8mol.% Y 2 o 3 ) mixed and ultrasonically stirred to obtain ZrO 2 suspension;

[0025] Step S102, to ZrO 2 Add 6.0mol·L to the suspension -1 Ammonia water 20mL with a concentration of 0.1mol·L -1 AlCl 3 15g of the solution was fully reacted and aged for 2 hours;

[0026] In step S103, the mixed solution is sequentially subjected to suction filtration, washing, drying, and calcination to obtain nano-alumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com