Thin-wall and high-pressure-resisting PE (Polyethylene) hose and preparation method thereof

A high-pressure, thin-walled technology, applied in tubular articles, other household appliances, applications, etc., can solve the problems of poor weather resistance, high meter weight, thick wall thickness, etc., to improve appearance quality, improve tensile yield strength, improve The effect of weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

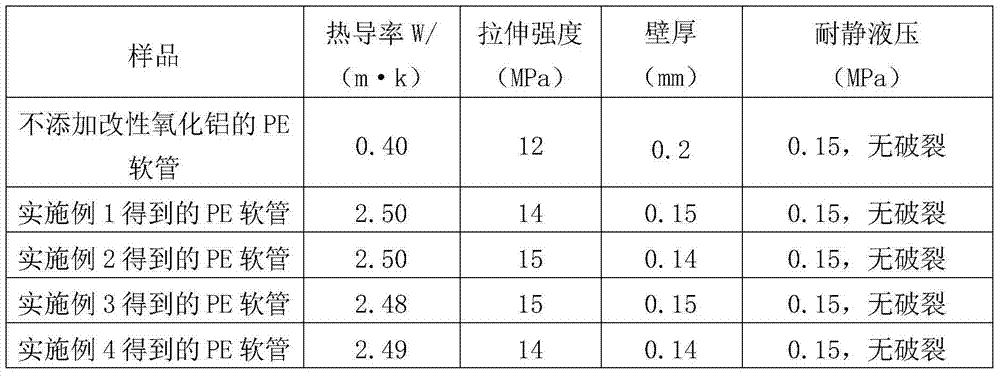

Examples

Embodiment 1

[0042] Thin-wall high-pressure resistant PE hose, prepared from the following components by weight percentage: 37% high-density polyethylene, 20% low-density polyethylene, 29% linear low-density polyethylene, 8% modified alumina , 3% fluoropolymer additive PPA functional masterbatch and 3% polyethylene black masterbatch.

[0043] Wherein, the particle size of the modified alumina is 800 mesh.

[0044] The reason for choosing modified alumina is that alumina is obtained by chemically treating bauxite raw materials to remove oxides such as silicon, iron, and titanium. It is a high-purity alumina raw material with an average Al?O? content. It is more than 99%, but there is a huge difference in the physical and chemical properties of unmodified alumina and polymer materials, which easily leads to poor wettability between different components during the compounding process, and the compounding quality is not high. Modified alumina is obtained by surface chemical modification, whic...

Embodiment 2

[0053] Thin-walled high-pressure resistant PE hose, prepared from the following components by weight percentage: 41% high-density polyethylene, 16% low-density polyethylene, 25% linear low-density polyethylene, 12% particle size of 1000 mesh Modified alumina, 2% fluoropolymer additive PPA functional masterbatch and 4% polyethylene black masterbatch.

[0054] The preparation method for realizing the thin-walled high-pressure resistant PE hose is the same as in Example 1.

Embodiment 3

[0056] Thin-walled high-pressure resistant PE hose, prepared from the following components by weight: 43% high-density polyethylene, 12% low-density polyethylene, 21% linear low-density polyethylene, 18% particle size of 1300 mesh Modified alumina, 1% fluoropolymer additive PPA functional masterbatch and 5% polyethylene black masterbatch.

[0057] The preparation method for realizing the thin-walled high-pressure resistant PE hose is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com