A kind of comprehensive recovery method of high arsenic antimony oxide dust

A high-arsenic, antimony-oxygen fume and recovery method technology, which is applied in the direction of metal recovery and recycling technology, can solve the problems of complex process, difficult separation, and low separation efficiency, and achieve low oxidant and alkali consumption, low energy consumption, and process Exhaust gas controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The comprehensive recovery method of high arsenic, antimony and oxygen dust in this embodiment comprises the following steps:

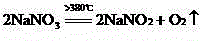

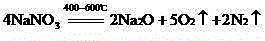

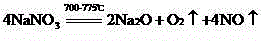

[0027] (1) Mix 100g of high-arsenic antimony oxide dust (including Sb35.04%, As26.71%) with sodium nitrate 34.3g (1.0 times the theoretical value of antimony and arsenic reaction in high-arsenic antimony oxide dust), sodium hydroxide 51.6 g (1.4 times the theoretical value of sodium antimonate and sodium arsenate) mixed evenly, put into a calciner and heat up at 400-500°C for calcination; after calcination for 30 minutes, cool to obtain 141.3g of calcined material (of which Sb24. 67%, As18.56%, Sb 3+ 0.005%, As 3+ 0.008%).

[0028] (2) Add the calcined material to 280mL of hot water at 70-75°C for 120 minutes, then filter to obtain sodium antimonate filter cake and sodium arsenate solution; dry the sodium antimonate filter cake and concentrated sodium arsenate solution , 59.5g of sodium antimonate (including 57.26% of Sb and 0.32% of As) and...

Embodiment 2

[0031] The comprehensive recovery method of high arsenic, antimony and oxygen dust in this embodiment comprises the following steps:

[0032] (1) Combine 200g of high-arsenic antimony oxide dust (including Sb74.89%, As5.78%) with 75.6g of sodium nitrate (1.1 times the theoretical value of antimony and arsenic reaction in high-arsenic antimony oxide dust), 44.1g of sodium carbonate (1.5 times the theoretical value to generate sodium antimonate and sodium arsenate) After mixing evenly, put it into a calciner, heat up to 500-550°C for calcination; after calcination for 45 minutes, cool to obtain 281.3g of calcined material (of which Sb52. 89%, As4.05%, Sb3+0.004%, As3+0.006%).

[0033] (2) Add the calcined material to 850mL of hot water at 80-90°C for 100 minutes, and then filter to obtain sodium antimonate filter cake and sodium arsenate solution; dry the sodium antimonate filter cake and concentrated sodium arsenate solution, respectively 229.1 g of sodium antimonate (includin...

Embodiment 3

[0036] The comprehensive recovery method of high arsenic, antimony and oxygen dust in this embodiment comprises the following steps:

[0037](1) Combine 246g of high-arsenic antimony oxide dust (including Sb15.06%, As30.56%) with 93.5g of sodium nitrate (1.3 times the theoretical value of antimony and arsenic reaction in high-arsenic antimony oxide dust), and 156.3g of sodium carbonate (1.6 times the theoretical value of sodium antimonate and sodium arsenate to produce sodium antimonate and sodium arsenate) After mixing evenly, put it into a calciner and heat up to 600-680°C for calcination; after calcination for 60 minutes, cool to obtain 371.9g of calcined material (of which Sb9.89 %, As19.89%, Sb 3+ 0.005%, As 3+ 0.006%).

[0038] (2) Add the calcined material to 1500mL of hot water at 90-100°C for 60 minutes, then filter to obtain sodium antimonate filter cake and sodium arsenate solution; dry the sodium antimonate filter cake and concentrated sodium arsenate solution 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com