A kind of molten salt electrolysis prepares the method for aluminum magnesium neodymium alloy

A molten salt electrolysis, aluminum-magnesium-neodymium technology, applied in the field of preparation of aluminum-magnesium rare earth alloys, can solve the problems of high cost and short process, and achieve the goals of improving recovery rate, increasing concentration, improving current efficiency and direct rare earth recovery rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

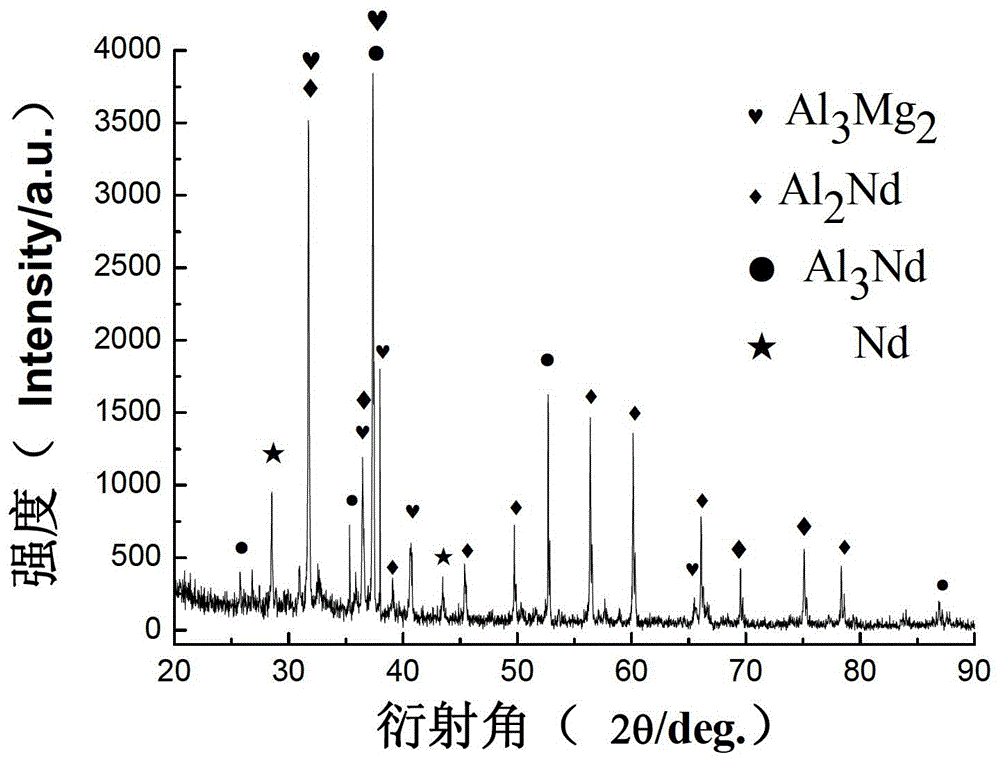

[0012] Example 1: In the electrolytic cell, metal molybdenum (Mo) is used as the inert cathode and placed at the bottom of the electrolytic cell, graphite is used as the anode, and dried and dehydrated AlF is added to the corundum crucible 3 , MgCl 2 , NaCl and KCl, the mass percentages of each component are 8.6%, 4.3%, 38.7%, 48.4% respectively, and then press AlF 3 2.5% of the mass added neodymium oxide (Nd 2 o 3 ), mix evenly, control the electrolysis temperature to 700°C, and the cathode current density to 6.92A / cm 2 , the anode current density is 0.85A / cm 2 , the voltage of the electrolytic cell is 4.8~4.9V. After 3 hours of electrolysis, Al-Mg-Nd ternary alloy is precipitated near the cathode of the electrolytic cell. The contents of Al, Mg and Nd in the alloy are 64.5%, 26.1%, 9.4% respectively. %, the current efficiency is 53.6%, and the direct recovery rate of rare earth is 68.8%.

Embodiment 2

[0013] Example 2: In the electrolytic cell, metal molybdenum (Mo) is used as the inert cathode and placed at the bottom of the electrolytic cell, graphite (C) is used as the anode, and dried and dehydrated AlF is added to the corundum crucible 3 , MgCl 2 , NaCl and KCl, the mass percentages of each component are 9.9%, 1.1%, 39.5%, 49.5%, and then press AlF 3 2.2% of the mass is added with neodymium oxide (Nd 2 o 3 ), mix evenly, control the electrolysis temperature to 700°C, and the cathode current density to 5.19A / cm 2 , the anode current density is 0.64A / cm 2 , the voltage of the electrolytic cell is 5.0~5.1V. After 2 hours of electrolysis, Al-Mg-Nd ternary alloy is precipitated near the cathode of the electrolytic cell. The contents of Al, Mg and Nd in the alloy are 89.4%, 3.3%, and 7.3% respectively , the current efficiency is 81.5%, and the direct recovery rate of rare earth is 37.7%.

Embodiment 3

[0014] Example 3: In the electrolytic cell, metal molybdenum (Mo) is used as the inert cathode and placed at the bottom of the electrolytic cell, graphite (C) is used as the anode, and dried and dehydrated AlF is added to the corundum crucible 3 , MgCl 2 , NaCl and KCl, the mass percentages of each component are 9.8%, 2.2%, 39.1%, 48.9% respectively, and then press AlF 3 2.2% of the mass is added with neodymium oxide (Nd 2 o 3 ), mix evenly, control the electrolysis temperature to 700°C, and the cathode current density to 5.19A / cm 2 , the anode current density is 0.64A / cm 2 , the voltage of the electrolytic cell is 5.0~5.1V, after 3 hours of electrolysis, the Al-Mg-Nd ternary alloy is precipitated near the cathode in the electrolytic cell, and the contents of Al, Mg and Nd in the alloy are 86.3%, 1.1%, respectively. 12.6%, the current efficiency is 75.6%, and the direct recovery rate of rare earth is 84.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com