A method for smelting pretreatment of waste circuit board multi-metal powder

A waste circuit board and multi-metal technology, which is applied in the field of smelting and pretreatment of waste circuit board multi-metal powder, can solve the problems of short processing process and loss of multi-metal powder, achieve simple and easy process, reduce copper content, avoid The effect of multi-metal powder oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

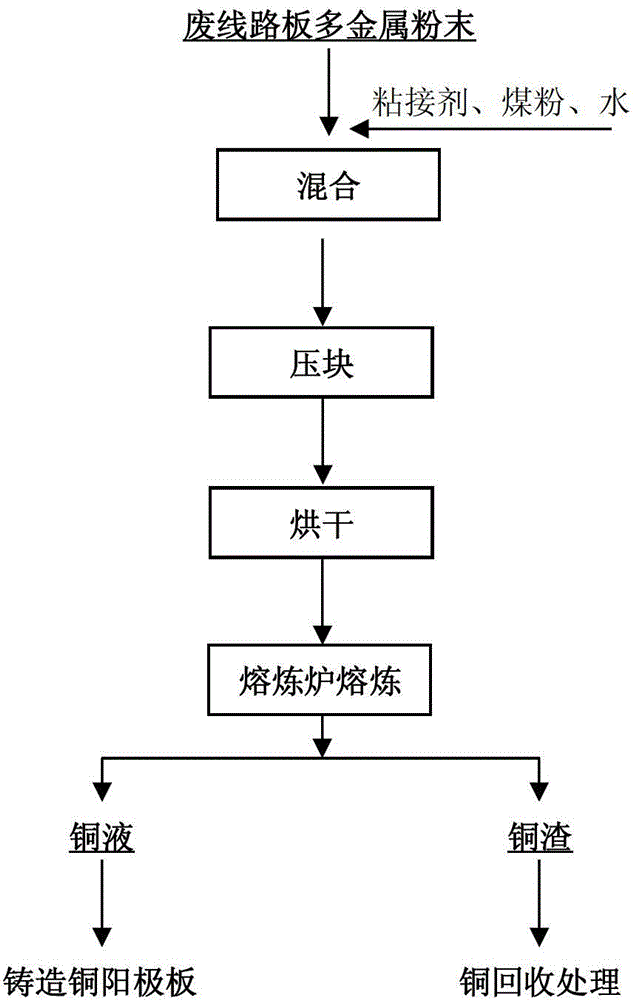

[0010] According to the design requirements, the waste circuit board polymetallic powder, adhesive, coal powder and water are mixed to obtain a mixed wet material, among which waste circuit board polymetallic powder: adhesive = 10:0.5 (mass), polymetallic powder: coal Powder = 10:0.15 (mass), polymetallic powder: water = 10:2 (mass), the binder is composed of bentonite and lime, silicon in the binder: calcium = 1.5:1 (mass); mix the wet material Put it into a briquetting machine to briquette to obtain a mixed block, the pressure of which is 0.3MPa; put the mixed block into a drying kiln for drying treatment to obtain a dried block, the drying treatment temperature is 100°C, and the drying time is The time is 12 hours; the dried block material is put into a smelting furnace for smelting to obtain copper slag and copper liquid, the copper slag is used for copper recovery treatment, and the copper liquid is cast into a copper anode plate. The copper slag rate is 9.5%, and the cop...

Embodiment 2

[0012] According to the design requirements, the waste circuit board polymetallic powder, adhesive, coal powder and water are mixed to obtain a mixed wet material, wherein the waste circuit board polymetallic powder: adhesive = 10:1 (mass), polymetallic powder: coal Powder = 10:0.25 (mass), polymetallic powder: water = 10:5 (mass), the binder is composed of bentonite and lime, silicon in the binder: calcium = 2.5:1 (mass); mix the wet material Put it into a briquetting machine to briquette to obtain a mixed block, the pressure of which is 0.8MPa; put the mixed block into a drying kiln for drying treatment to obtain a dried block, the drying treatment temperature is 150°C, and the drying time The time is 24 hours; put the dried block material into the smelting furnace for smelting to obtain copper slag and copper liquid, the copper slag is used for copper recovery treatment, and the copper liquid is cast into a copper anode plate. The copper slag rate is 9.7%, and the copper co...

Embodiment 3

[0014] According to the design requirements, the waste circuit board polymetallic powder, adhesive, coal powder and water are mixed to obtain a mixed wet material, among which waste circuit board polymetallic powder: adhesive = 10:0.8 (mass), polymetallic powder: coal Powder = 10:0.2 (mass), polymetallic powder: water = 10:3 (mass), the binder is composed of bentonite and lime, silicon in the binder: calcium = 2:1 (mass); mix the wet material Put it into a briquetting machine to briquette to obtain a mixed block, the pressure of which is 0.6MPa; put the mixed block into a drying kiln for drying treatment to obtain a dried block, the drying treatment temperature is 120°C, and the drying time is 16 hours; add the dried block material into the smelting furnace for smelting to obtain copper slag and copper liquid, the copper slag is used for copper recovery treatment, and the copper liquid is cast into a copper anode plate. The copper slag rate is 9.1%, and the copper content rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com