Process for recycling oil base mud from oil base mud well drilling waste

A technology for drilling waste and oil-based mud, which is applied in the technical field of recovering oil-based mud from oil-based mud drilling waste, can solve the problems of pollutant diffusion, secondary pollution, and high environmental conditions, and achieve economic benefits and Uniform environmental benefits, strong anti-wear and blocking ability, good stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A resource recycling project of diesel-based mud in oil-based drilling waste was implemented in an oilfield in Xinjiang. Oil-based drilling waste mainly includes waste oil-based mud and oily drilling cuttings, with an oil content of about 20-30%. In this embodiment, the drilling process is mainly sandstone, and the cuttings are mainly sandstone particles. The particle size of the cuttings is relatively large, about 0.2-10mm, and the mechanical strength and hardness of the particles are relatively high. Rotating speed. The design approved treatment capacity is 0.5m 3 / h equipment to investigate the processing capacity, processing effect and process stability of the process.

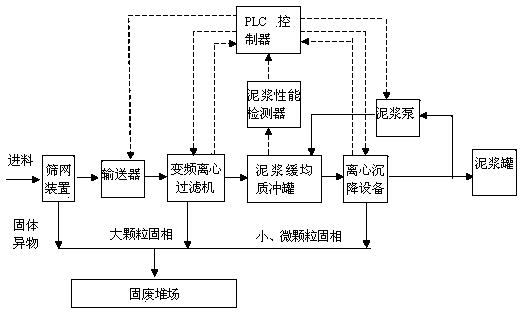

[0031] combine figure 1 , The feed section is equipped with a feed screen with an aperture of 4cm to prevent foreign matter from entering the centrifugal filter equipment and causing blockage. After passing through the feeding screen, the maximum particle size of the solid phase is 3~4cm, the med...

Embodiment 2

[0049] A resource recycling project of diesel-based mud in oil-based drilling waste was implemented in an oilfield in Xinjiang. The drilling process was dominated by sandstone, and the characteristics of the drilling waste material were the same as in Example 1. In this example, the design and approved treatment capacity was adopted. 3m 3 / h equipment to investigate the processing capacity, processing effect and process stability of the process.

[0050] In the feeding section, a feeding screen is added, and the aperture of the screen is 3cm. After passing through the feeding screen, the maximum particle size of the solid phase is 2.6cm, the median particle size is about 1.0mm, and the liquid content of the solid phase is about 21 %.

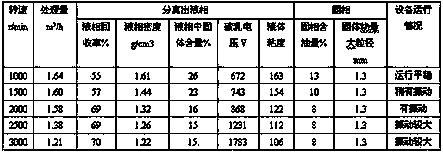

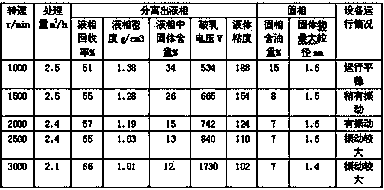

[0051] Comprehensive selection of filters with apertures of 0.5, 0.8, 1.5, 2.0, 4.0, and 5.0 mm for centrifugal filtration, the centrifugal speed is 1000r / min, the implementation effect of centrifugal filtration with different apertures is show...

Embodiment 3

[0066] A resource recycling project of diesel-based mud in oil-based drilling waste was implemented in an oilfield in Xinjiang. In this example, the drilling process was dominated by mudstone, and the drilling cuttings mainly included mudstone cuttings, whose particle mechanical strength was low, and the particle The diameter is small, about 0.05~0.1mm. In this embodiment, the design approved treatment capacity is 0.5m 3 / h equipment to investigate the processing capacity, processing effect and process stability of the process. The process includes feed filtration, centrifugal filtration, and centrifugal sedimentation.

[0067] The feeding section is equipped with a feeding screen with an aperture of 3 cm. After passing through the feeding screen, the maximum particle size of the solid phase is 2.6 cm, the median particle size is about 1.0 mm, and the liquid content of the solid phase is about 16%.

[0068] During the implementation process, in view of the small particle size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Maximum particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com