Ultralow-energy-consumption nitrogen making device

An energy-consumption, ultra-low technology, applied in the field of ultra-low energy-consumption nitrogen generators, can solve the problems of inflexible equipment adjustment and inability to meet the energy consumption requirements of users' air separation equipment, and achieve considerable economic benefits, maximizing economic benefits, and achieving effective results. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

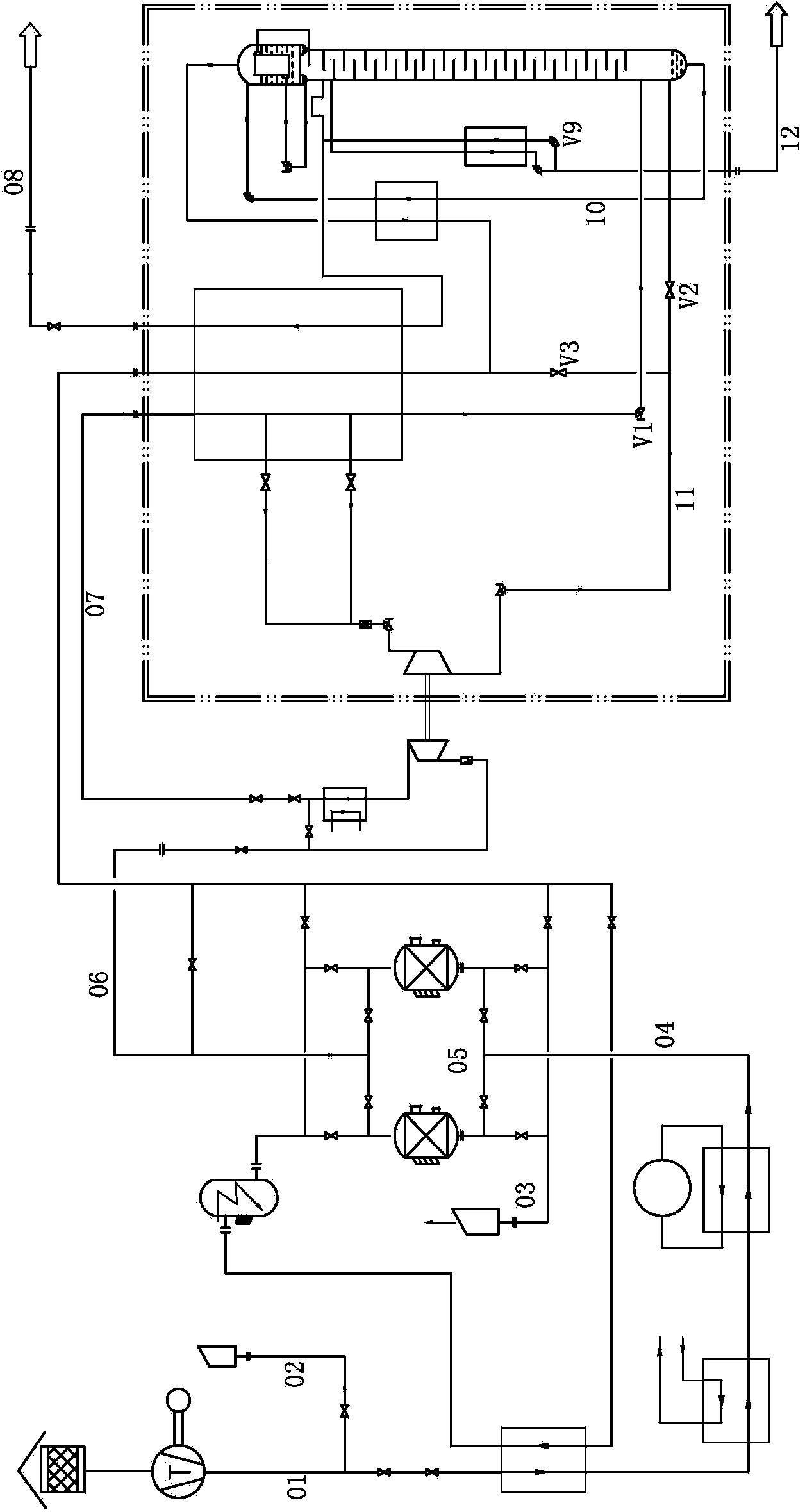

[0015] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 :

[0016] A low-energy nitrogen production device, including a rectification tower C1, a condensing evaporator K1, a booster turbo expander, a main heat exchanger E1, a liquid-air subcooler E2, and a nitrogen subcooler E3 connected by pipes and valves , the air passes through the pipelines 01, 04, 05, 06, 07, 11 in turn through the air filter AF, air compressor AC, sewage nitrogen heat exchanger E1001, water cooler WC, pre-cooling unit RU, molecular sieve purifier MS and main After the heat exchanger E1, it directly enters the bottom of the rectification tower C1 or enters the bottom of the rectification tower C1 after being expanded and pressurized by a booster turbo expander. The oxygen-enriched liquid air is obtained at the bottom of the rectification tower C1, and the liquid is passed through the pipeline 10. Empty subcooler E2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com