Strain liquid crystal dimming display glassware and manufacturing method thereof

A technology for glass products and strained liquid crystals, applied in optics, nonlinear optics, instruments, etc., can solve the problems of difficult production, chipping and other problems, and achieve the effect of not easily broken

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

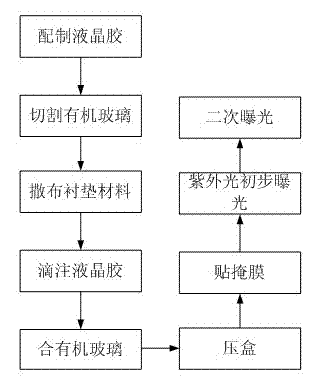

[0026] 1. Preparation of liquid crystal glue: Mix and prepare the following ingredients according to the following mass percentages: 30% alkoxy nonyl phenyl acrylate, 60% trimethylolpropane triacrylate, 4% nitrile rubber, 2-mercaptoethanol 4%, 1173 photoinitiator 2%, to form a prepolymer, stir the prepolymer at room temperature for 1 minute and mix well, then mix the prepolymer and nematic liquid crystal at a mass ratio of 15:7, Stir at room temperature for 1 minute to fully mix to form liquid crystal glue, which is colorless and transparent with low viscosity;

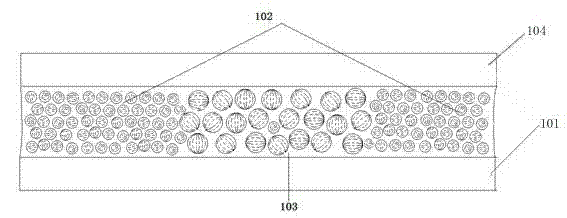

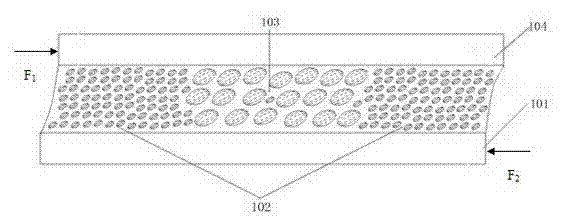

[0027] 2. Cut plexiglass: cut plexiglass 101 with a thickness of 3 mm into 5×5cm 2 Wipe the plexiglass 101 substrate with a soft paper towel to make the surface clean and free of dirt, and the edges are smooth and free of burrs;

[0028] 3. Spread the cushioning material: dip a small amount of cushioning material with a small brush and evenly spread a proper amount of cushioning material on the piece of plexiglass 10...

Embodiment 2

[0037] 1. Preparation of liquid crystal glue: Mix and prepare the following ingredients according to the following mass percentages: 30% alkoxy nonyl phenyl acrylate, 60% trimethylolpropane triacrylate, 4% nitrile rubber, 2-mercaptoethanol 4%, 1173 photoinitiator 2%, form a prepolymer, stir the prepolymer at room temperature for 1.5 minutes and mix well, then mix the prepolymer and nematic liquid crystal at a mass ratio of 2:1 , stirred at room temperature for 1.5 minutes to make it fully mixed to form a liquid crystal glue, which is colorless and transparent, and has a low viscosity;

[0038] 2. Cut plexiglass: cut the plexiglass 101 with a thickness of 3mm into 5×5cm 2 Wipe the plexiglass 101 substrate with a soft paper towel to make the surface clean and free of dirt, and the edges are smooth and free of burrs;

[0039] 3. Spread the cushioning material: dip a small amount of cushioning material with a small brush and evenly spread a proper amount of cushioning material on...

Embodiment 3

[0048] 1. Preparation of liquid crystal glue: Mix and prepare the following ingredients according to the following mass percentages: 30% alkoxy nonyl phenyl acrylate, 60% trimethylolpropane triacrylate, 4% nitrile rubber, 2-mercaptoethanol 4%, 1173 photoinitiator 2%, form a prepolymer, stir the prepolymer at room temperature for 2 minutes and mix well, then mix the prepolymer and nematic liquid crystal at a mass ratio of 13:7 , stirred at room temperature for 2 minutes to make it fully mixed to form a liquid crystal glue, which is colorless and transparent, and has a low viscosity;

[0049] 2. Cut plexiglass: cut the plexiglass 101 with a thickness of 3mm into 5×5cm 2 Wipe the plexiglass 101 substrate with a soft paper towel to make the surface clean and free of dirt, and the edges are smooth and free of burrs;

[0050] 3. Spread the cushioning material: dip a small amount of cushioning material with a small brush and evenly spread a proper amount of cushioning material on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com