Light emitting diode encapsulating structure

A technology of light-emitting diodes and packaging structures, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of increased temperature control costs, bulky, inconvenient lamp design, etc., and achieve the effect of improving light output, excellent performance and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

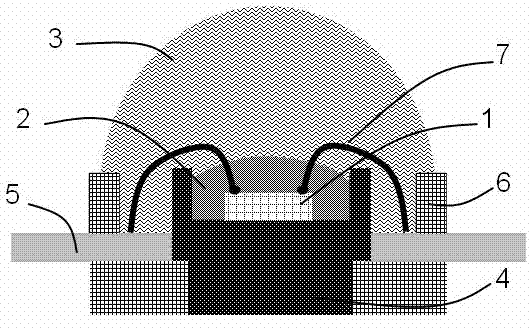

[0012] The structure diagram of the present invention is as figure 1 As shown, the light-emitting diode packaging structure of the present invention includes an LED bracket bowl 4, an LED chip 1 placed on the LED bracket bowl 4, and an LED bracket bowl 4 and an LED chip 1 placed on the LED bracket bowl 4. For potting protection, the LED chip 1 is connected to the LED metal lead wire 7, and the LED bracket cup and bowl 4 is connected to the bracket pin 5, wherein a phase change material is installed between the outside of the LED chip 1 and the outside of the transparent potting material 3 2. The phase change material 2 is a solid at normal temperature, but it is a transparent liquid when the LED chip 1 works stably.

[0013] In this embodiment, the phase change material 2 is poured on the outside of the LED chip 1 , the phase change material 2 seals and wraps the LED chip 1 , and the transparent potting material 3 seals and wraps the phase change material 2 and the LED chip 1 ...

Embodiment 2

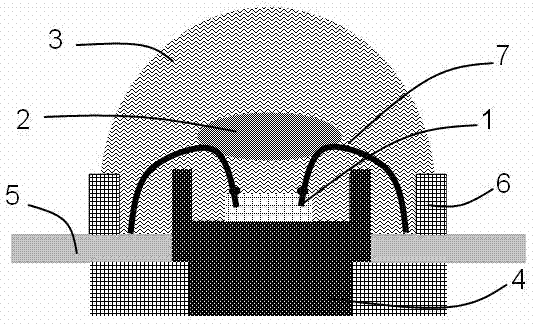

[0024] Embodiment 2 of the present invention is similar to Embodiment 1. The difference between Embodiment 2 of the present invention and Embodiment 1 is that the phase-change material 2, taking paraffin wax as an example, can be sealed and packaged on the premise that the transparent potting material 3 can be guaranteed Next, instead of directly covering the surface of the LED chip 1 , the phase change material 2 is poured into any position between the transparent potting material 3 and the LED chip 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com