Power module

一种功率模块、导体板的技术,应用在操作模式、电动汽车、电动/混合动力等方向,能够解决剥离、绝缘层周围端部龟裂等问题,达到缓和应力、可靠性提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach -

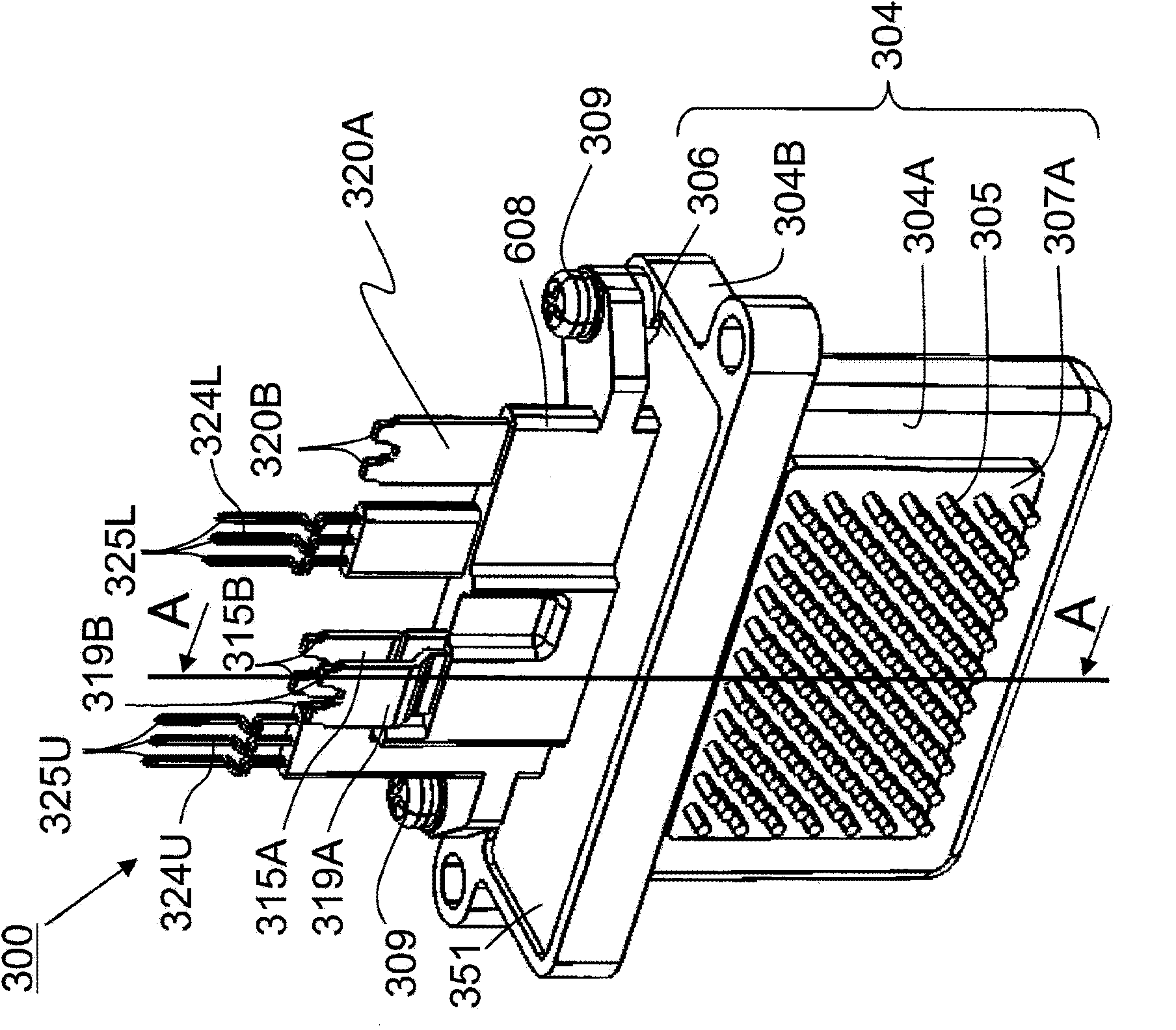

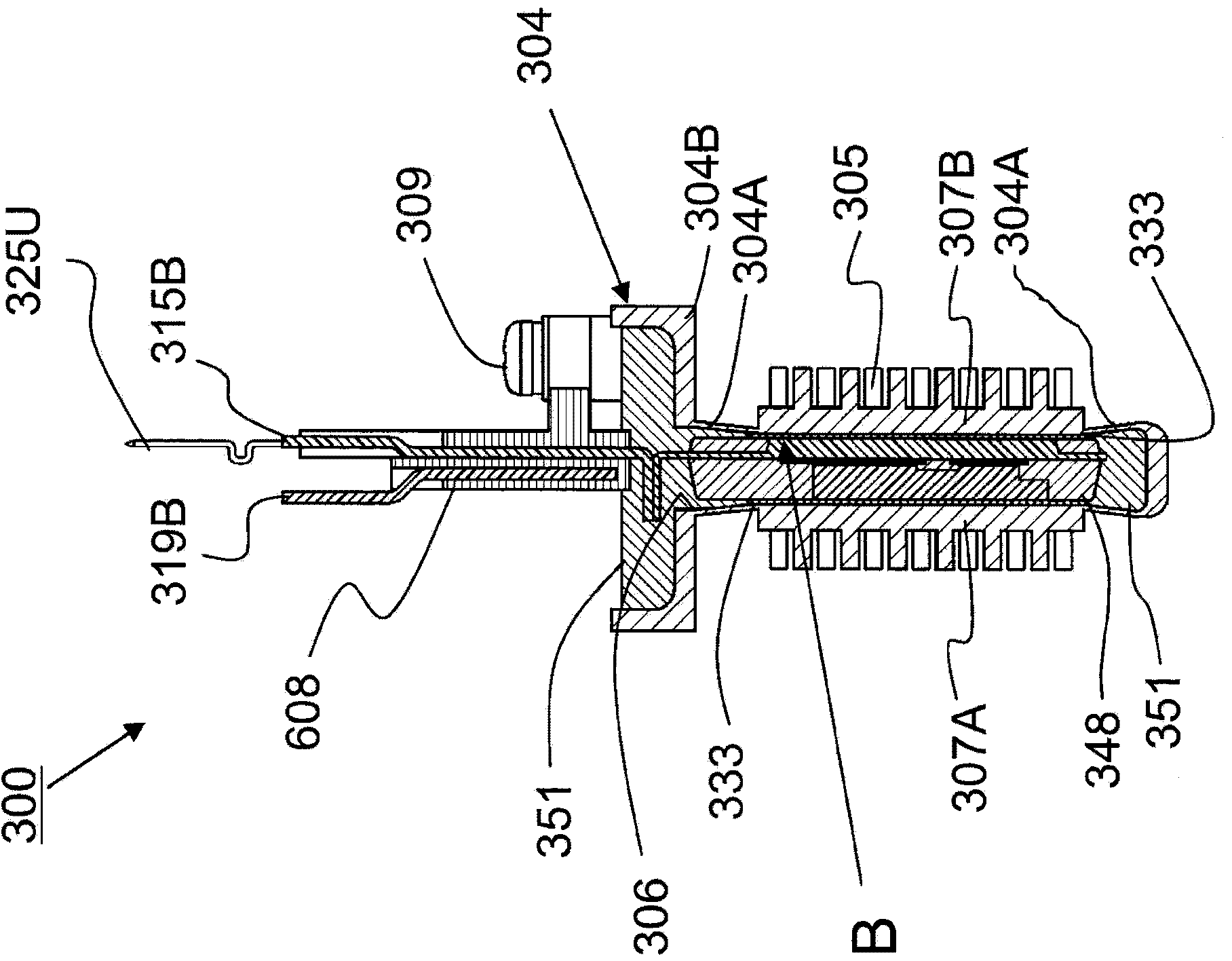

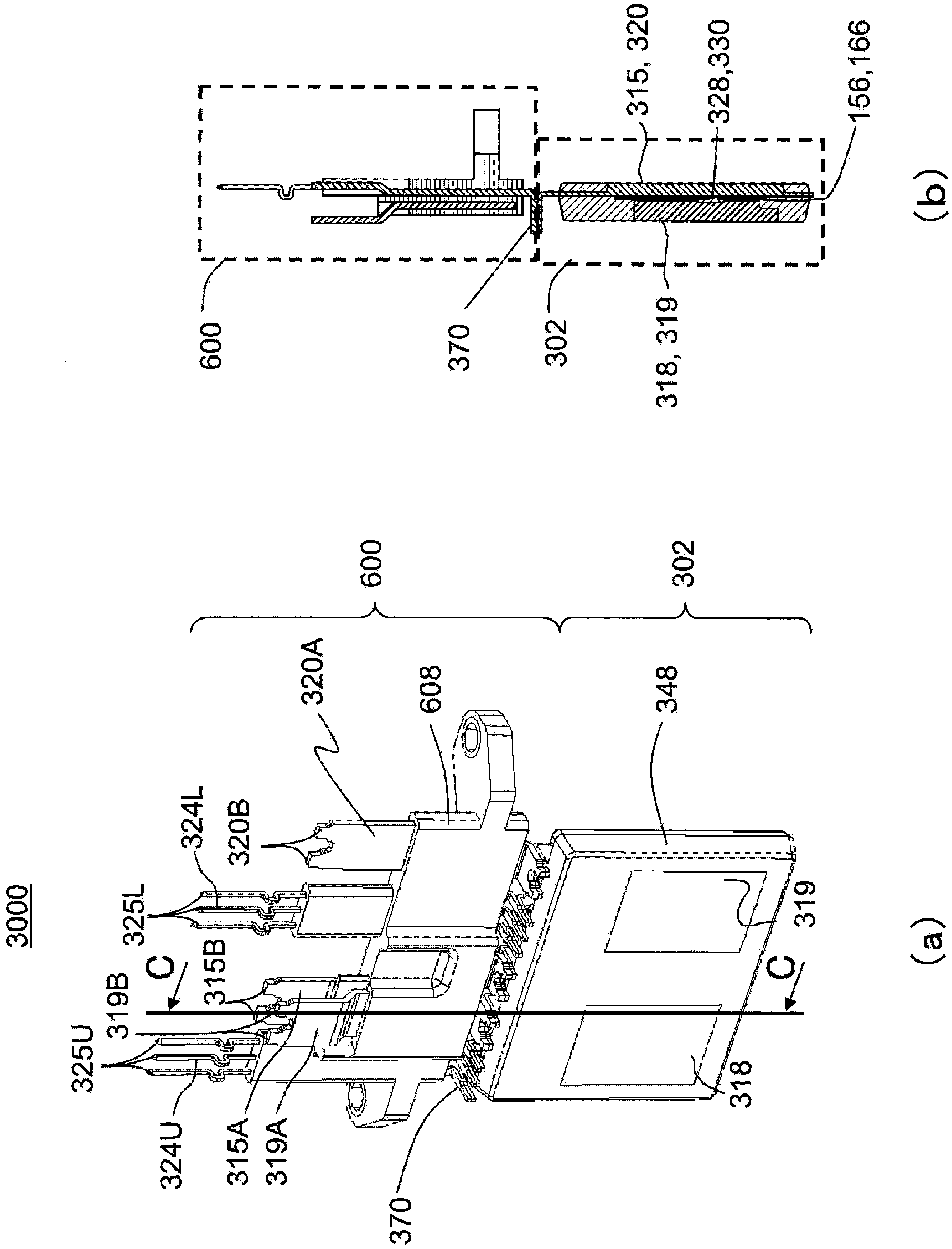

[0064] Figure 1-17 It is a figure which shows 1st Embodiment of the power module of this invention. figure 1 It is a perspective view of the external appearance of the power module. figure 2 yes figure 1 A-A cutaway view. The power module 300 includes switching elements and accommodates a power semiconductor unit of a transfer mold in a module case 304 . The power module 300 can be used, for example, in a power conversion device mounted on an electric vehicle such as an electric car or a hybrid car.

[0065] Such as figure 2 As shown, the power module 300 will image 3 The illustrated power module structure 3000 is housed inside a module case 304 that is a CAN-type cooler. Here, the CAN-type cooler is a cooler formed in a cylindrical shape having an insertion opening 306 on one side and a bottom on the other side. The module case 304 is formed of a member having electrical conductivity, for example, a composite material such as Cu, Cu alloy, Cu—C, Cu—CuO, or a compos...

no. 2 approach -

[0123] Figures 18-21 It is a figure which shows 2nd Embodiment. Figure 18 is a sectional view of the power module. In addition, illustration of the auxiliary mold body 600 of the primary sealing body 302 is omitted. In the first embodiment, the module case 304 is integrally formed, but in the second embodiment, the module case 304 is composed of a case frame and a pair of case side parts. The casing frame is composed of a thick flange 304B and a frame portion 304D. One of the pair of housing side surfaces 304C (the left side in the drawing) is composed of a heat dissipation portion 307A on which a heat dissipation fin 305 is formed, and a thin portion 304A surrounding the periphery thereof. The other case side surface portion 304C is composed of a heat dissipation portion 307B on which the heat dissipation fins 305 are formed, and a thin portion 304A surrounding the periphery thereof. The module case 304 is formed by metal-connecting the thin portion 304A to the case fra...

no. 3 approach -

[0136] Figure 22 It is a figure explaining 3rd Embodiment. As in the above-mentioned second mode, by providing the resin portion 333C with a lower elastic modulus or a higher adhesive force at the peripheral end portion of the laminate composed of the thermal sprayed film 333A and the resin layer 333B, stress concentration on the end portion and peeling can be prevented. Generates and progresses from the end. In the third embodiment, by increasing the amount of resin constituting the resin portion 333C, the effect of alleviating stress concentration is further enhanced.

[0137] exist Figure 22 In the example shown, the resin for impregnation (the same resin as that of the resin portion 333C) overflows a lot, and a straightening band (a portion overflowing from the gap) 333F is formed. In the method of forming the laminated body described in the first embodiment, the amount of resin when impregnated into the sprayed coating 333A is increased so as to protrude more toward ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com