Preparation method for diamine cross-linked modified polyimide nano-filtration membrane added with polyethylene glycol

A polyimide nano, polyethylene glycol technology, applied in the field of polyimide nanofiltration membrane preparation, can solve the problem of high preparation cost, low retention rate, low permeation flux of polyimide nanofiltration membrane, etc. problem, to achieve the effect of simple operation, reduced energy consumption and outstanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0023] Specific embodiment one: the preparation method of the polyimide nanofiltration membrane of a kind of diamine cross-linking modification adding polyethylene glycol in this embodiment, is to carry out according to the following steps:

[0024] 1. Preparation of polyimide casting solution: dissolve 15g-25g of substance A into 75g-85g of substance B, and after mixing evenly, obtain a polyimide casting solution with a mass fraction of 15%-25%;

[0025] The substance A described in step 1 is polyetherimide, bismaleimide or LenzingP84; the substance B described is dimethylformamide, tetrahydrofuran, N-methylpyrrolidone, N-methylformamide amides, dimethylacetamide or dimethylsulfoxide;

[0026] 2. Add polyethylene glycol: Add polyethylene glycol to the polyimide casting solution obtained in step 1, and stir for 0.5h to 10h at a stirring speed of 50r / min to 300r / min to obtain Polyethylene glycol-polyimide casting solution;

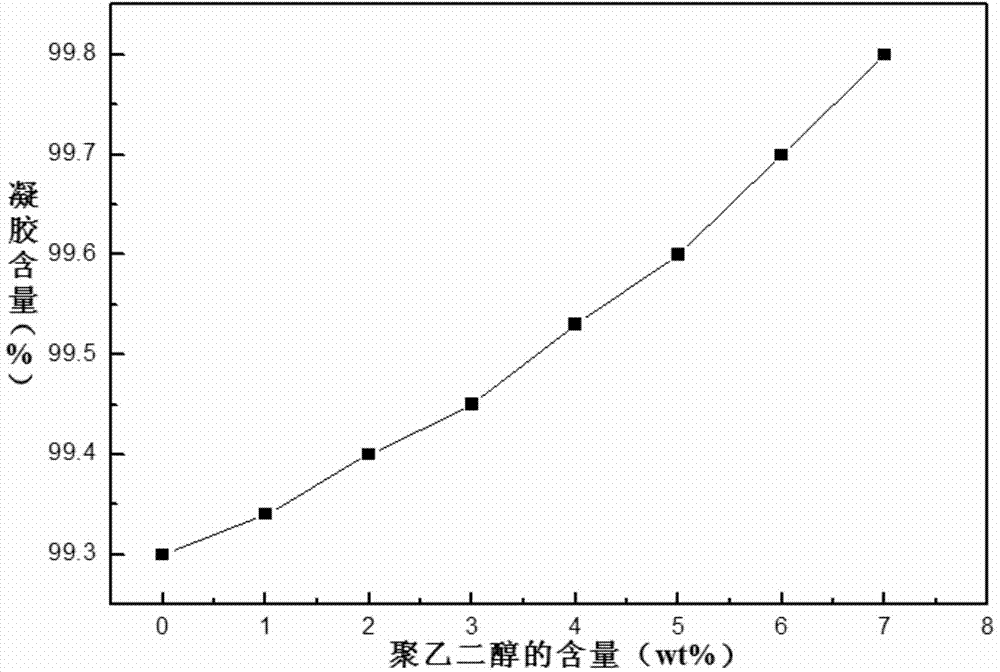

[0027] The mass percent of polyethylene glycol in t...

specific Embodiment approach 2

[0034] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the mass percentage of polyethylene glycol in the polyethylene glycol-polyimide casting solution obtained in step 2 is 1wt%~19wt% . Others are the same as the first embodiment.

specific Embodiment approach 3

[0035] Specific embodiment three: The difference between this embodiment and specific embodiment one or two is that the mass percentage of polyethylene glycol in the polyethylene glycol-polyimide casting solution obtained in step two is 2wt%~ 18wt%. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com