Vinyl acetate catalyst during acetylene method, preparation method for catalyst and synthesis method for vinyl acetate

A vinyl acetate and catalyst technology, applied in the field of acetylene method vinyl acetate catalyst and its preparation and synthesis of vinyl acetate, can solve the problems of short life and low catalyst activity, achieve good technical effect, suppress loss and carbon deposition, and benefit The effect of catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Catalyst preparation

[0021] (a) Preparation of impregnation solution: weigh 18.0 g Zn(OAc) 2 Solid, dissolved in 180 ml deionized water, heated to 60°C and stirred at constant temperature until completely dissolved, prepared as Zn(OAc) 2 For the impregnation solution with a content of 100.0 g / L, the pH value of the above impregnation solution was adjusted to 4.5 by HAc.

[0022] (b) Impregnation of the support: The selected SiC support has a specific surface area of 121.3 cm 2 / g, the pore volume with a pore diameter of 2-50 nm accounted for 62.9% of the total pore volume, 100 ml of the SiC carrier was added to the above impregnation solution, and the impregnation was carried out at a temperature of 75 °C.

[0023] (c) Drying: After impregnation, the catalyst was dried at 105 °C for 6 h, and the obtained catalyst could be evaluated for catalyst performance after being loaded into the reactor.

[0024] (2) Characterization of physical properties

[0025] Use ...

Embodiment 2

[0036] (1) Catalyst preparation

[0037] (a) Preparation of impregnation solution: weigh 18.0 g Zn(OAc) 2 Solid, 1.83 g FeCl 3 ·6H 2 O solid, dissolved in 180 ml deionized water, heated to 60°C and stirred at constant temperature until completely dissolved, prepared as Zn(OAc) 2 Content 100.0 g / L, FeCl 3 For the impregnating solution with a content of 6.11 g / L, the pH value of the above impregnating solution was adjusted to 4.5 by HAc.

[0038] (b) Impregnation of the support: The selected SiC support has a specific surface area of 121.3 cm 2 / g, the pore volume with a pore diameter of 2-50 nm accounted for 62.9% of the total pore volume, 100 ml of the SiC carrier was added to the above impregnation solution, and the impregnation was carried out at a temperature of 75 °C.

[0039] (c) Drying: After impregnation, the catalyst was dried at 105 °C for 6 h, and the obtained catalyst could be evaluated for catalyst performance after being loaded into the reactor.

[0040] O...

Embodiment 3

[0041] [Example 3] to [Example 11]

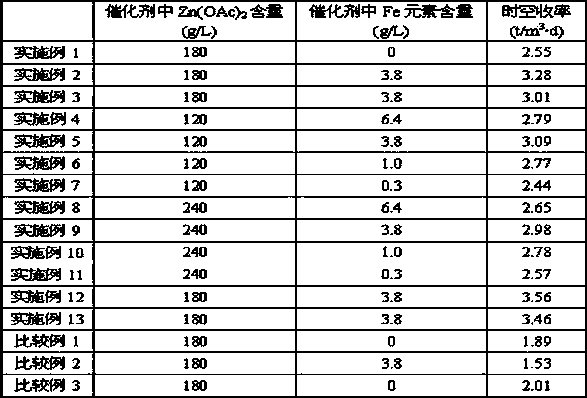

[0042] In addition to changing the Zn(OAc) in the immersion solution 2 Content, type and content of water-soluble iron salt, SiC supports with different specific surface areas and pore size distributions, impregnation temperature and drying temperature, other operating steps and catalyst evaluation conditions are the same as in Example 2. For the convenience of comparison, the preparation conditions of the catalysts are listed in Table 1, and the characterization and evaluation data of the catalysts are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com