The Accurate Method of Assembling the Slanted Connecting Pipes on Large-diameter Metal Cylinders

A metal cylinder and large-diameter technology, which is applied in metal processing, metal processing equipment, welding equipment, etc., can solve the problem that it is difficult to meet the requirements of accurate assembly and welding of obliquely inserted pipes on large-diameter metal cylinders, and the inability to meet the requirements of large-diameter metal cylinders. Problems such as the precise assembly of the upwardly inclined connecting pipe and the cylinder body achieve the effect of reducing production costs and high assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

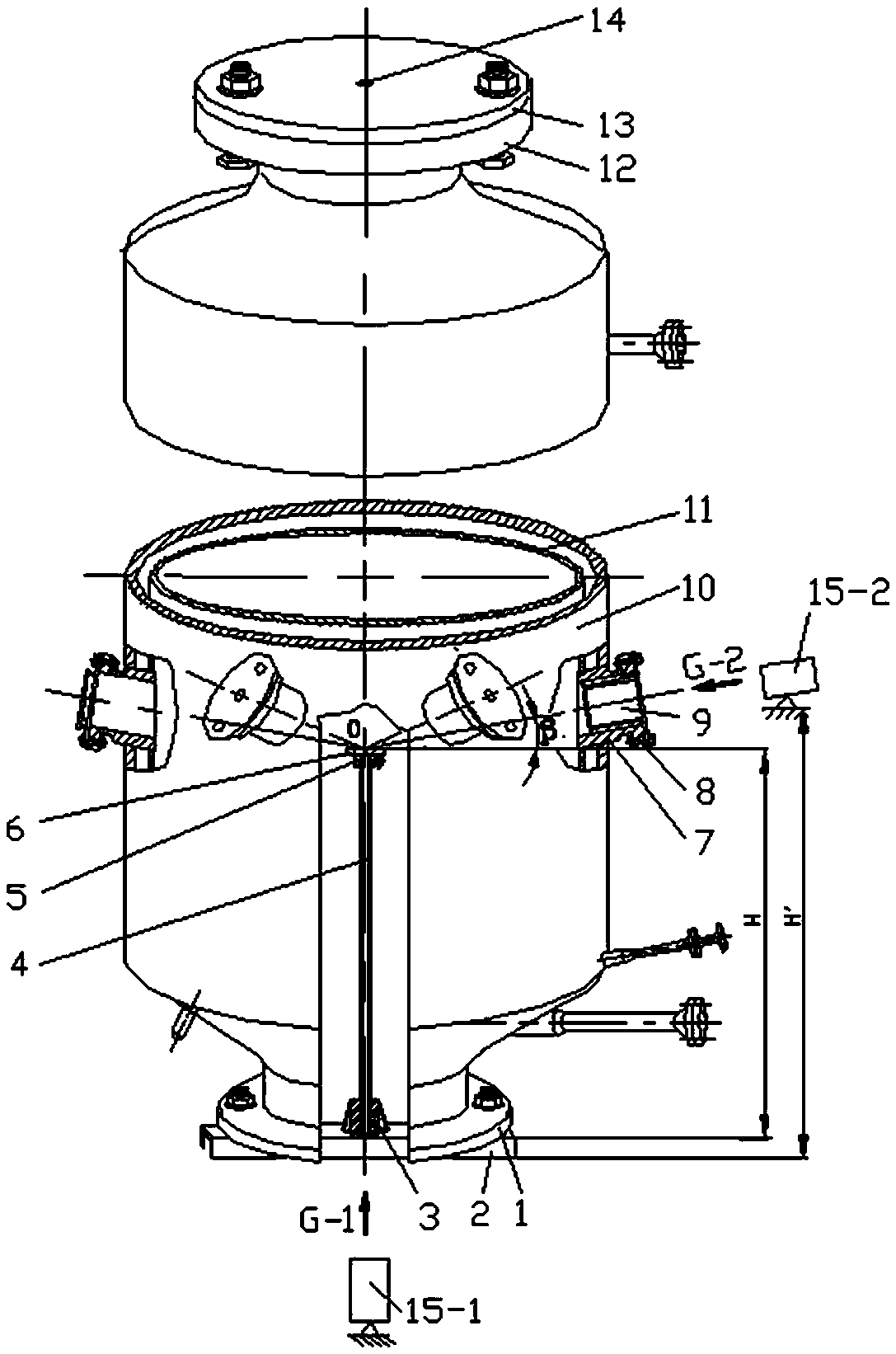

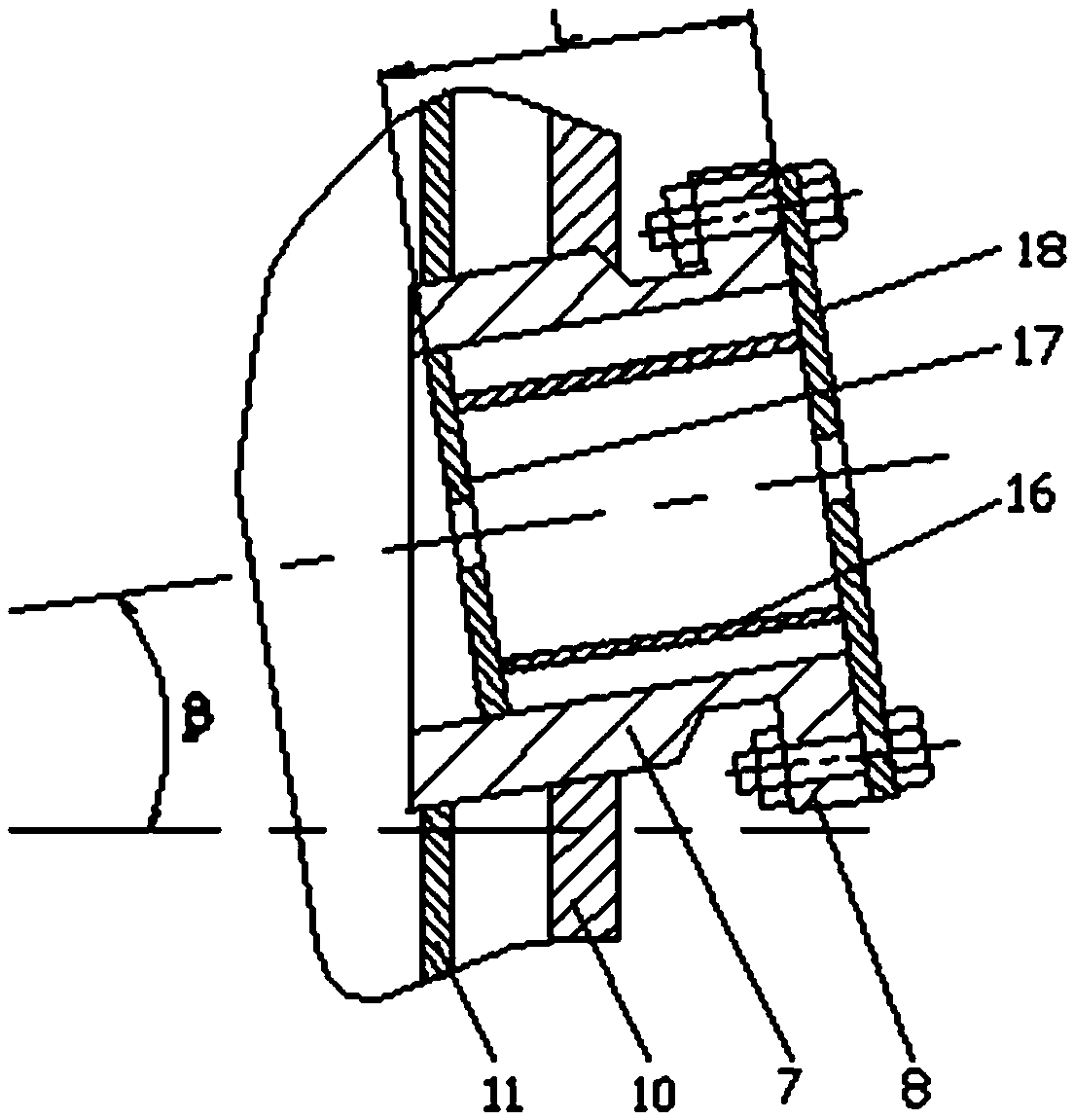

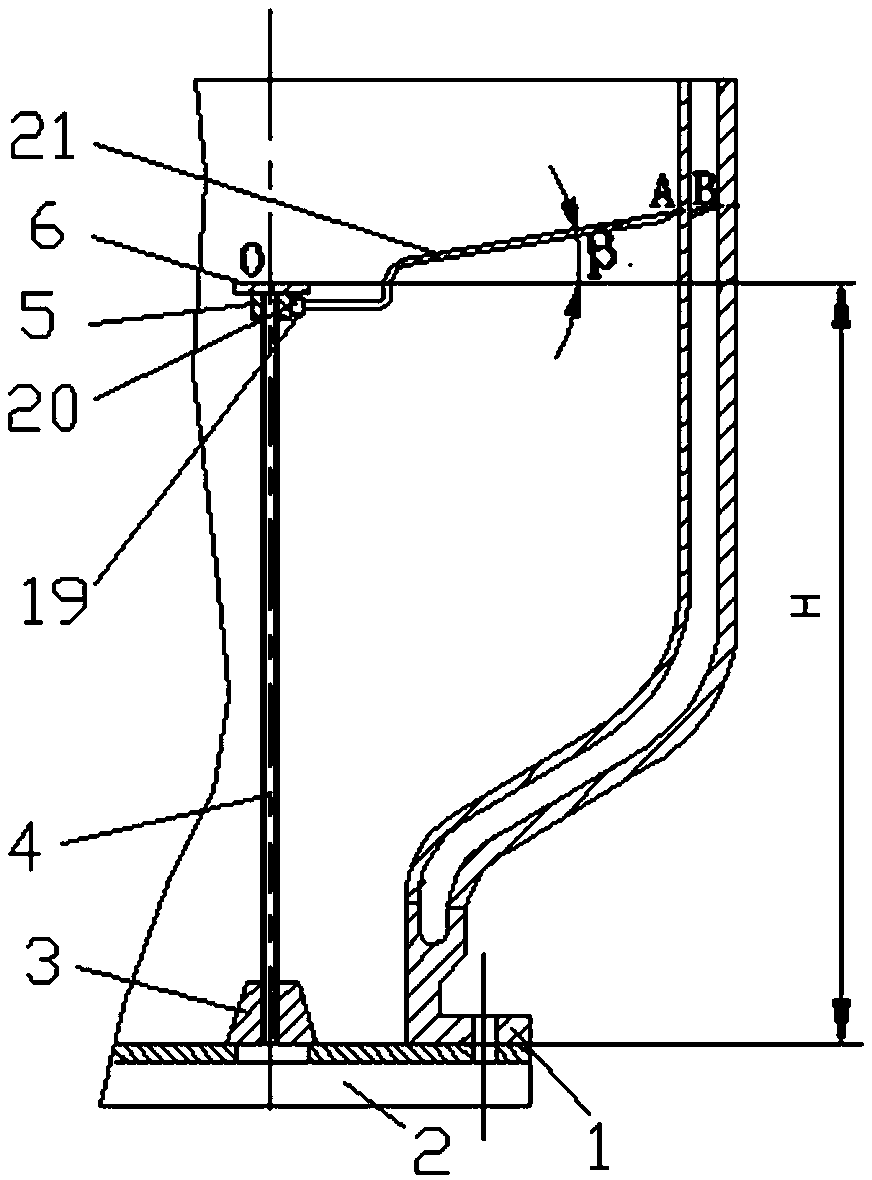

[0025] The φ4400㎜ crushed coal slag gasifier is a jacketed pressure vessel with an inner cylinder. Equipment specifications: the inner diameter of the cylinder is 4000mm, the wall thickness is 75mm, and the material is 13MnNiMoR; the inner diameter of the inner cylinder is 4150mm, the wall thickness is 38mm, and the material is Q345R. There are 6 tuyeres at the lower part of the cylinder body 10, and the obliquely inserted connecting pipes 7 of the 6 tuyeres are evenly distributed along the furnace body. The inner diameter of the obliquely inserted connecting pipes of the 6 tuyeres is 300mm. The included angle between the axis of the socket tube and the vertical plane of the longitudinal axis of the cylinder is β, and the angle error is only ±5', and it is required that the axis lines of the oblique sockets of the six tuyeres intersect with the cylinder after assembly and welding The same point O on the center line of the longitudinal axis; the distance from point O to the bot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com