Method for preparing sodium metasilicate and light calcium carbonate with green liquid generated in alkali recovery in papermaking by straw pulp

A light calcium carbonate, straw pulp papermaking alkali technology, applied in the direction of alkali metal silicate, calcium carbonate/strontium/barium, silicate, etc., can solve the destruction of land resources, pollution of land and groundwater, ecological environment damage, etc problems, to achieve the effect of improving strength and whiteness, significant economic benefits, and eradicating environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

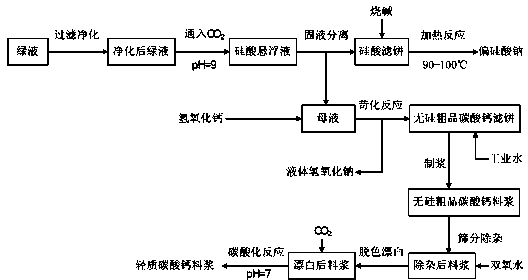

Image

Examples

Embodiment 1

[0026] (1) Preparation of sodium metasilicate: Take 1L of green liquor produced by the conventional process of recycling straw pulp and papermaking alkali, and vacuum filter it with a 4G sand core funnel at room temperature to obtain clear and transparent green liquor; the purified green liquor Carbon dioxide gas was introduced into the medium, and after a certain period of reaction, the green liquid began to be cloudy. As the reaction progressed, a large number of white flocs appeared in the green liquid. When the pH of the liquid was measured to be 9, the reaction was stopped and a silicic acid suspension was obtained. ;The silicic acid suspension was subjected to vacuum filtration to obtain a silicic acid filter cake, and the mass of the silicic acid filter cake was weighed to be 114.5g; In the acid filter cake, the quality of silicon dioxide is 6.396g. Put 114.5g of silicic acid filter cake into a 250mL beaker, then add 8.67g of caustic soda with a sodium hydroxide content ...

Embodiment 2

[0029](1) Preparation of sodium metasilicate: Take 10L of green liquor produced by the conventional process of recycling straw pulp and papermaking alkali, and vacuum filter it with a 4G sand core funnel at room temperature to obtain clear and transparent green liquor; the purified green liquor Carbon dioxide gas was introduced into the medium, and after a certain period of reaction, the green liquid began to be cloudy. As the reaction progressed, a large number of white flocs appeared in the green liquid. When the pH of the liquid was measured to be 9, the reaction was stopped and a silicic acid suspension was obtained. ; The silicic acid suspension was vacuum filtered to obtain a silicic acid filter cake, and the quality of the silicic acid filter cake was 980g; the volume of the mother liquor (green liquid after filtering out silicic acid) was 9L; In the cake, the mass of silica is 60g. Put 980g of silicic acid filter cake into a 3000mL beaker, then add 81g of caustic soda w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com