Preparation method of micropore hollow ball molecular sieve

A molecular sieve and hollow sphere technology, used in molecular sieve catalysts, chemical instruments and methods, refining to remove heteroatoms, etc., can solve the problems of spherical structure collapse, easy fracture of silicon oxide connections, and inability to make hollow molecular sieve spheres. The effect of reduced losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

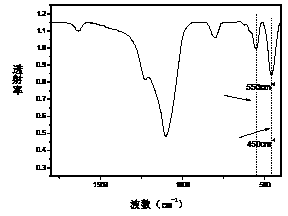

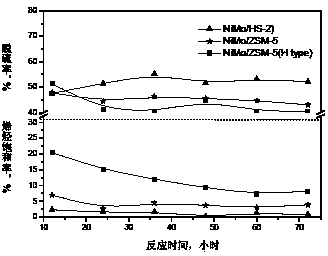

Embodiment 1

[0021] put 10.5 g NaAlO 2 and 56 mL of TPAOH were dissolved in 100 mL of deionized water to obtain a solution with a pH value of about 9, and then weigh the raw material mesoporous silica solid ball molecular sieve (properties: particle size is 400nm, average pore diameter is 2.9nm , the specific surface area is 1080m 2 / g, the pore volume is greater than 0.35cm 3 / g) 100 grams, transferred to a Buchner funnel with filter paper, and added the previously prepared solution drop by drop to the raw material on the filter paper in the state of suction filtration under reduced pressure. After suction filtration and wetting, it was transferred to a crystallization kettle and crystallized at 170°C for 48 hours. Cool the crystallized slurry to room temperature, and filter the obtained powder under reduced pressure until the pH of the washing liquid is close to neutral; dry at 70°C for 10 hours; then bake at 540°C for 6 hours, the resulting molecular sieve is labeled HS-1, and its pr...

Embodiment 2

[0023] put 2.1 g NaAlO 2 and 28mL TPAOH were dissolved in 50 mL of deionized water to obtain a solution, the pH value of the solution was about 9, and then the raw material (mesoporous silica solid ball molecular sieve with a particle size of 400nm, a pore size of 2.9nm, and a specific surface area 1080m 2 / g, the pore volume is greater than 0.35cm 3 / g) 50 grams, transferred to a Buchner funnel with filter paper, and added the previously prepared solution drop by drop to the raw material on the filter paper in the state of suction filtration under reduced pressure. After suction filtration and wetting, it was transferred to a crystallization kettle and crystallized at 170°C for 48 hours. Cool the crystallized slurry to room temperature, and filter the obtained powder under reduced pressure until the pH of the washing liquid is close to neutral; dry at 70°C for 10 hours; then bake at 540°C for 6 hours, the resulting molecular sieve is labeled HS-2, and its properties are sh...

Embodiment 3

[0025] put 2.1 g NaAlO 2 and 84 mL of TPAOH were dissolved in 150 mL of deionized water to obtain a solution, the pH of which was about 9, and then the raw material (mesoporous silica solid ball molecular sieve with a particle size of 400 nm and a pore size of 2.9 nm, the ratio Surface area is 1080m 2 / g, the pore volume is greater than 0.35cm 3 / g) 150 grams, transferred to a Buchner funnel with filter paper, and added the previously prepared solution drop by drop to the raw material on the filter paper in the state of suction filtration under reduced pressure. After suction filtration and wetting, it was transferred to a crystallization kettle and crystallized at 170°C for 48 hours. Cool the crystallized slurry to room temperature, and filter the obtained powder under reduced pressure until the pH of the washing liquid is close to neutral; dry at 70°C for 10 hours; then bake at 540°C for 6 hours, the resulting molecular sieve is labeled HS-3, and its properties are shown ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average pore diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com