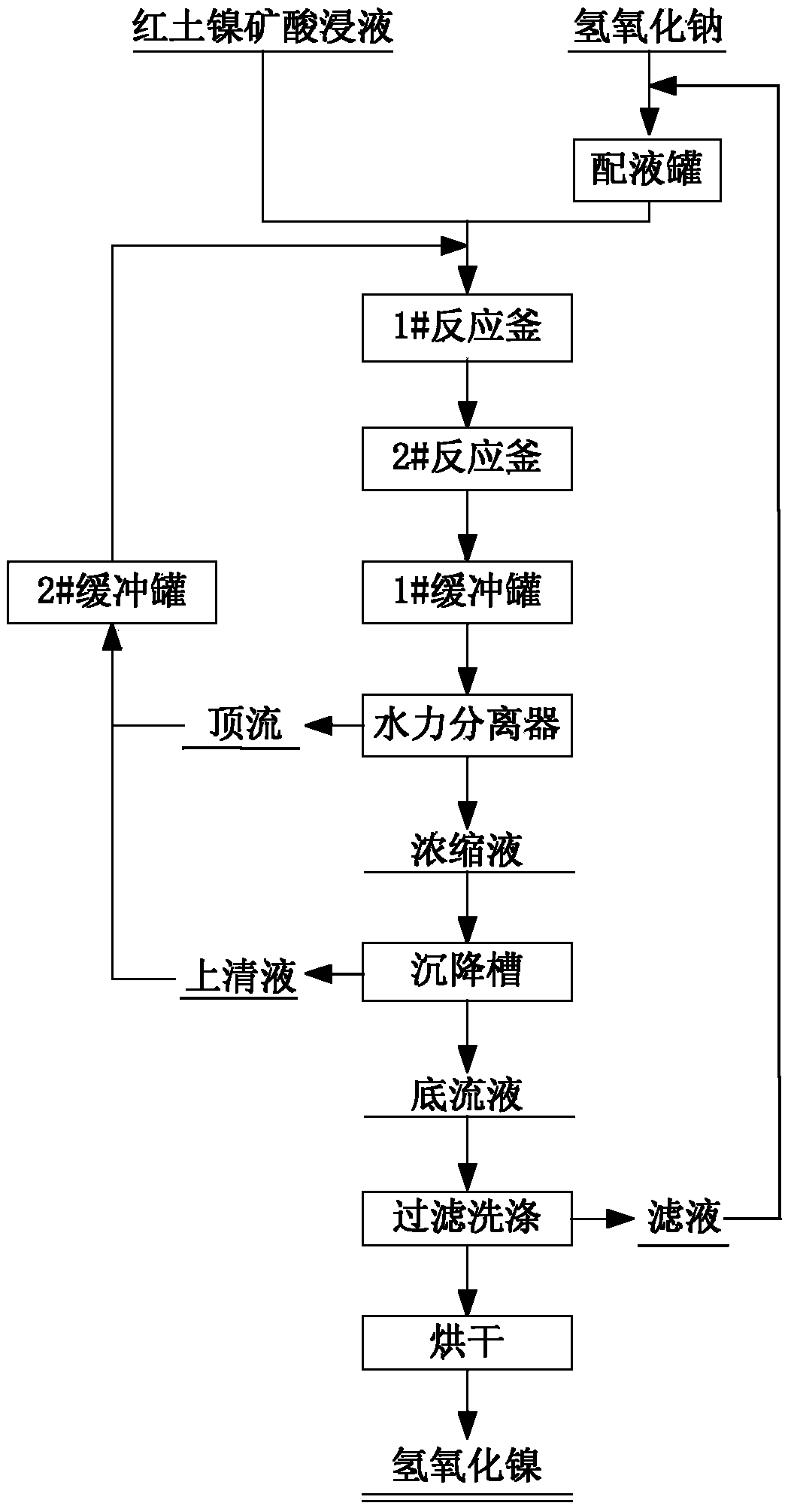

Process for continuously producing nickel hydroxide by using pickle liquor of nickel laterite ore

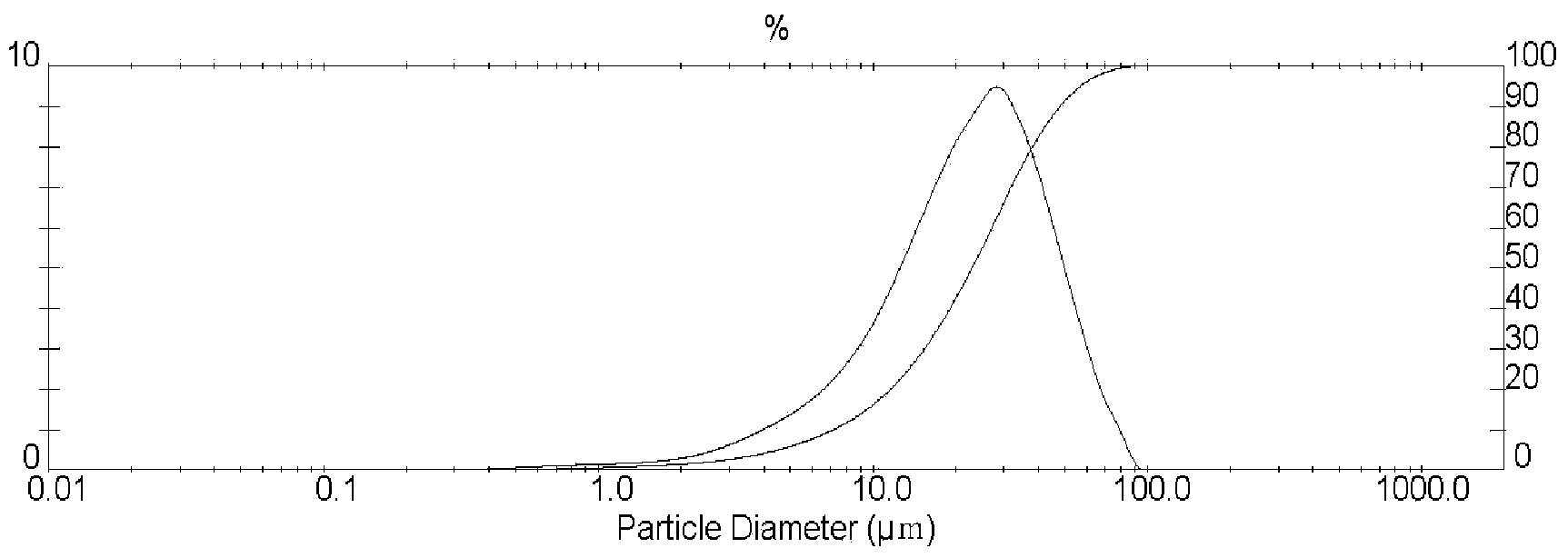

A technology of laterite nickel ore and nickel hydroxide, applied in nickel oxide/nickel hydroxide and other directions, can solve the problems of fine nickel hydroxide particles, difficult to control reaction system, low production efficiency, etc., and achieve uniform particle size, low cost, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028]The process of continuous production of nickel hydroxide with laterite nickel ore acid leaching solution is to add 1L of laterite nickel ore acid leaching solution with a nickel ion concentration of 2g / L to the 1# reaction kettle, heat up and stir and keep the temperature in the kettle at 45°C, and then add 1L # Add sodium hydroxide solution (mass concentration: 0.8%) into the reactor at a flow rate of 0.5 L / h to react. When the pH of the reaction system in the 1# reactor is 7.5, add laterite nickel ore acid leaching solution to the 1# reactor at a flow rate of 2.0L / h, and add sodium hydroxide solution at the same time to control the pH of the reaction system to 7.5. 1# Reactor The outflowing slurry is pumped into the 2# reactor to continue the reaction, and the temperature in the 2# reactor is controlled to be 45°C. The reaction slurry flows into the 1# buffer tank through the overflow port of the upper part of the 2# reactor for aging, and the pump into the hydrocyclon...

Embodiment 2

[0030] The process of continuous production of nickel hydroxide with laterite nickel ore acid leaching solution is to add 1L of laterite nickel ore acid leaching solution with a nickel ion concentration of 2g / L to the 1# reaction kettle, heat up and stir and keep the temperature in the kettle at 50°C, and then add 1L # Add sodium hydroxide solution (mass concentration: 0.8%) into the reactor at a flow rate of 0.5 L / h to react. When the pH of the reaction system in the 1# kettle is 7.5, open the laterite nickel ore acid leaching solution and add it to the 1# reaction kettle at a flow rate of 2.0L / h, and at the same time adjust the sodium hydroxide metering pump to control the pH of the reaction solution in the 1# kettle It is 7.5. The slurry flowing out of the 1# reactor is pumped into the 2# reactor to continue the reaction. The temperature in the 2# reactor is controlled at 50°C, and the reaction slurry flows into the 1# through the overflow port in the upper part of the 2# re...

Embodiment 3

[0032] The process of continuous production of nickel hydroxide with laterite nickel ore acid leaching solution is to add 1L of laterite nickel ore acid leaching solution with a nickel ion concentration of 3g / L to 1# reaction kettle, heat up and stir and keep the temperature in the kettle at 45°C, and then add 1L # Add sodium hydroxide solution (mass concentration: 1.2%) to the reaction kettle at a flow rate of 0.5 L / h to react. When the pH of the reaction system in the 1# kettle is 7.5, open the laterite nickel ore acid leaching solution, add it to the 1# reaction kettle at a flow rate of 2.0L / h, and adjust the amount of sodium hydroxide added to make the pH of the reaction solution in the 1# kettle is 7.5. The reaction liquid flows into the 2# reactor with a stirring paddle through the overflow port of the 1# reactor to continue the reaction. The temperature in the 2# reactor is controlled at 45°C, and the reaction liquid flows into the Aging in the 1# buffer tank, pumped i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com