Synergetic treatment method of energy-saving dehydration and efficient heavy metal removal of sewage and sludge

A sewage sludge and synergistic treatment technology, applied in dewatering/drying/concentrating sludge treatment, etc., can solve the problems of difficult disposal of sewage, high acidity and alkalinity of wastewater, improve dehydration performance, reduce heavy metal concentration, and reduce organic harmful substances Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

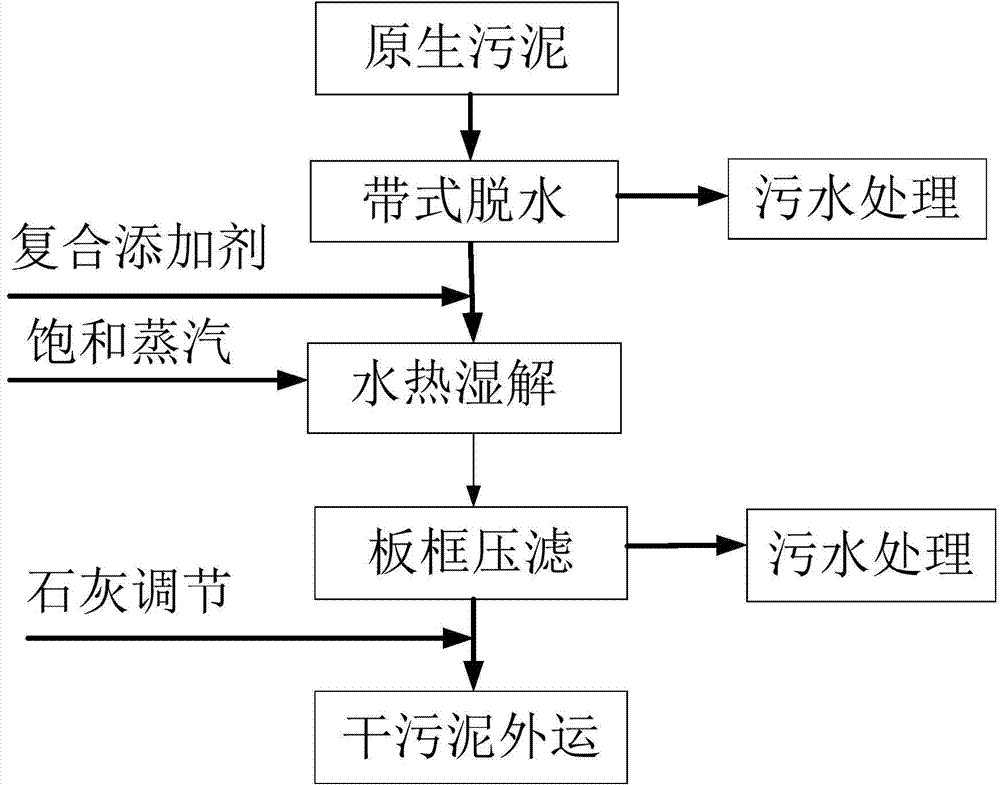

Method used

Image

Examples

Embodiment 1

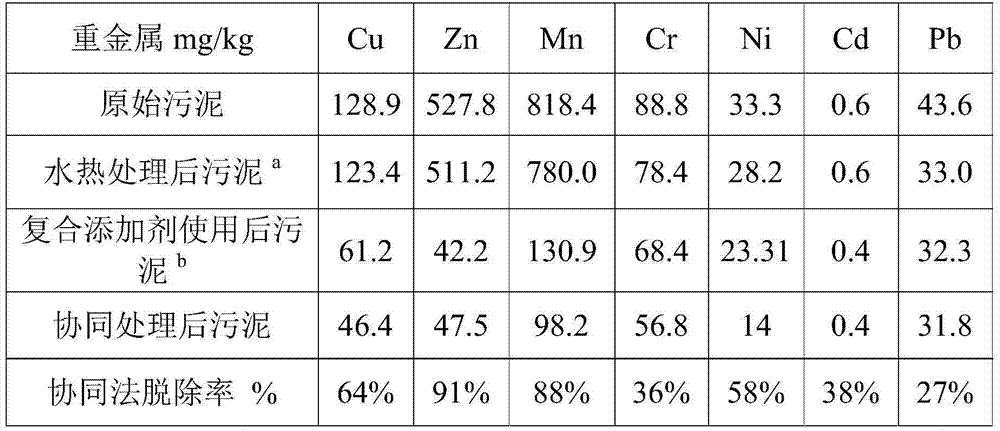

[0021] Primary sludge with a moisture content of 98.7% was mechanically dehydrated by a belt filter press in Hangzhou Qige Sewage Treatment Plant to obtain primary dewatered sludge with a moisture content of 82%. Collect 10kg of primary dewatered sludge and bring it back to the laboratory for refrigeration; 100.0g of dewatered sludge once, add 2.0g of composite additives (HEDTA, oxalic acid and NH 4 NO 3 Mixture with a mass ratio of 17:2:1) is fully stirred and mixed evenly, and the sludge is transferred into the hydrothermal reactor; the stirring motor is turned on at a speed of 100r / min, and then the electric heating is turned on (the actual project can directly pass saturated steam) to make The temperature of the hydrothermal reactor is raised to 160°C, the pressure is at 450kPa, and maintained for 60 minutes. After the time is met, stop the electric heating and cool the reactor; after the reactor cools down, stop the stirring motor and take out the sludge, and use the plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com