Inferior material hydrotreating method

A hydroprocessing and raw material technology, which is applied in hydroprocessing process, hydrocarbon oil treatment, petroleum industry, etc., can solve the problem of harsh operating conditions of wax oil hydroprocessing unit, limited circulation of catalytic cracking heavy cycle oil, and inability to guarantee the equipment Long-term operation and other problems, to reduce the clogging of catalyst pores, improve the effect of impurity removal, and prolong the service life

Active Publication Date: 2014-05-07

CHINA PETROLEUM & CHEM CORP +1

View PDF12 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the circulation rate of catalytic cracking heavy cycle oil in this method is limited, generally no more than 20%, and the operating conditions of the wax oil hydrotreating unit are relatively harsh, which cannot guarantee the long-term operation of the unit, and the quality of the produced oil of the hydrotreating unit be affected

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0029] Comparative example 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

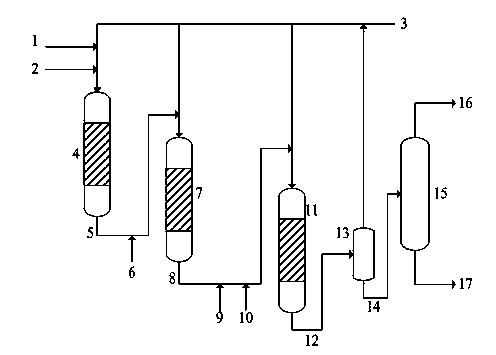

The invention relates to an inferior material hydrotreating method comprising the following steps: deasphalted oil and catalytic cracking oil slurry are mixed, and enter into a hydrodemetallization reaction zone for reaction under the effects of hydrogen and a metal catalyst, a hydrodemetallizated effluent and coker gas oil are mixed, and enter into a first hydrotreating reaction zone for reaction under the effects of the hydrogen and a hydrotreating catalyst, a hydrotreated effluent and one or two of vacuum gas oil and catalytic diesel oil are mixed, and enter into a second hydrotreating reaction zone for reaction under the effects of the hydrogen and the hydrotreating catalyst, and a reaction effluent is separated to obtain t hydrotreated oil. According to the method, an inferior material is segmentally treated, the device operation flexibility and impurity removing effect can be improved, the hydrotreating reaction severity can be reduced, the catalyst deactivation rate can be slowed down, and the device operation cycle can be prolonged.

Description

technical field [0001] The invention relates to a method for hydrogenation treatment of inferior raw materials, in particular to a method capable of segmentally treating multiple inferior raw materials. Background technique [0002] At present, the nature of crude oil in the world is gradually becoming heavier and worse, coupled with the continuous development of the world economy and increasingly stringent environmental protection regulations, it is necessary to produce a large amount of light and clean fuels, all of which require the improvement and improvement of the existing refining technology to Produce products that meet the requirements at the lowest cost. [0003] Catalytic cracking (FCC) continues to play an important role in the processing of heavy feedstocks to produce light products. The quality of light oil products directly produced by catalytic cracking technology is poor, especially the sulfur content of catalytic gasoline is relatively high, the sulfur con...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10G65/02

Inventor 崔哲王旭王仲义吴子明

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com