Structure for reinforcing tunnel by utilizing arch rings and method for reinforcing tunnel

A technology for tunnels and arch rings, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc. It can solve the problems of limited tunnel effects, high cost, and large steel consumption, and achieve good reinforcement effects, strong resistance to deformation, and high bearing capacity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

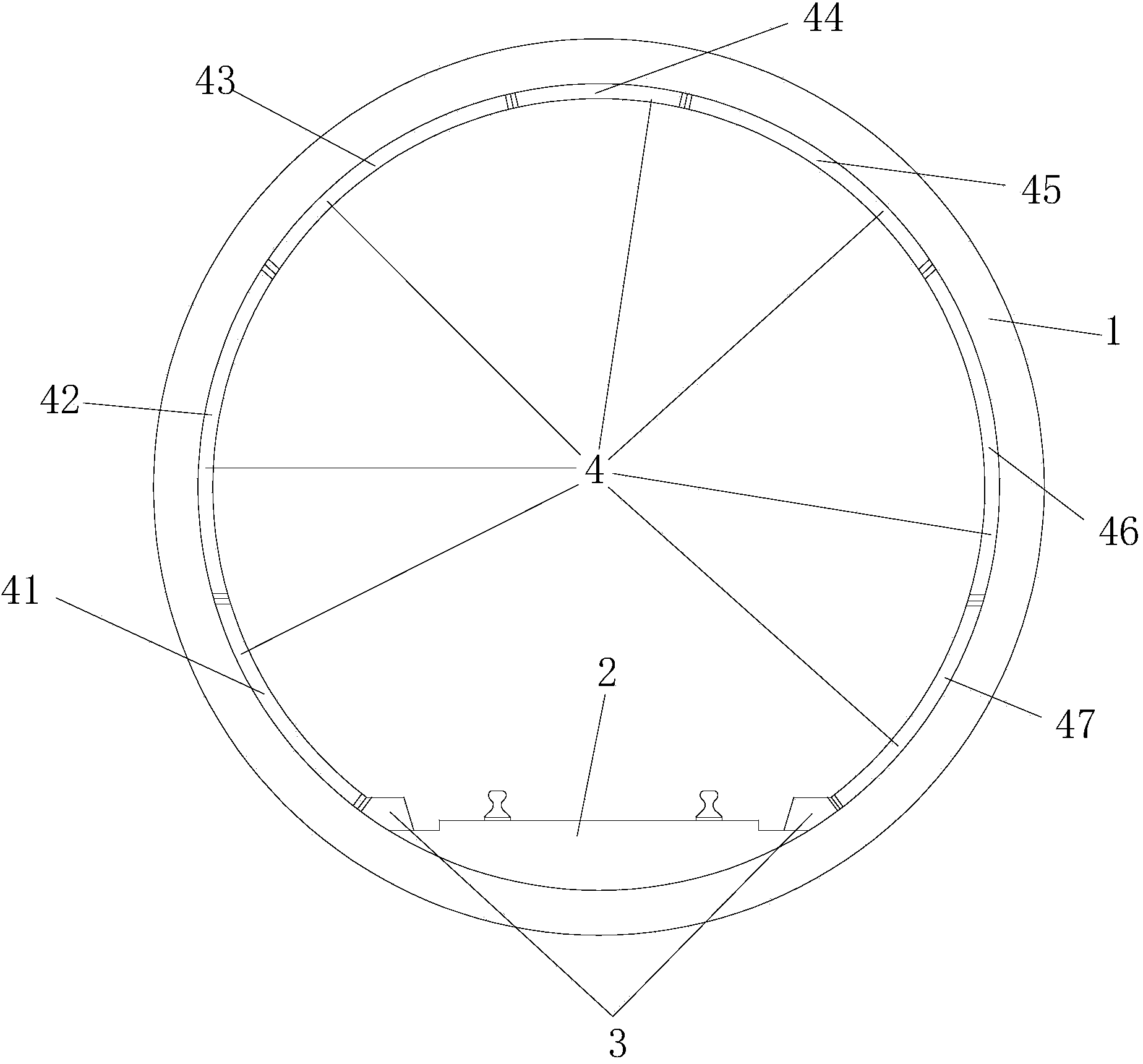

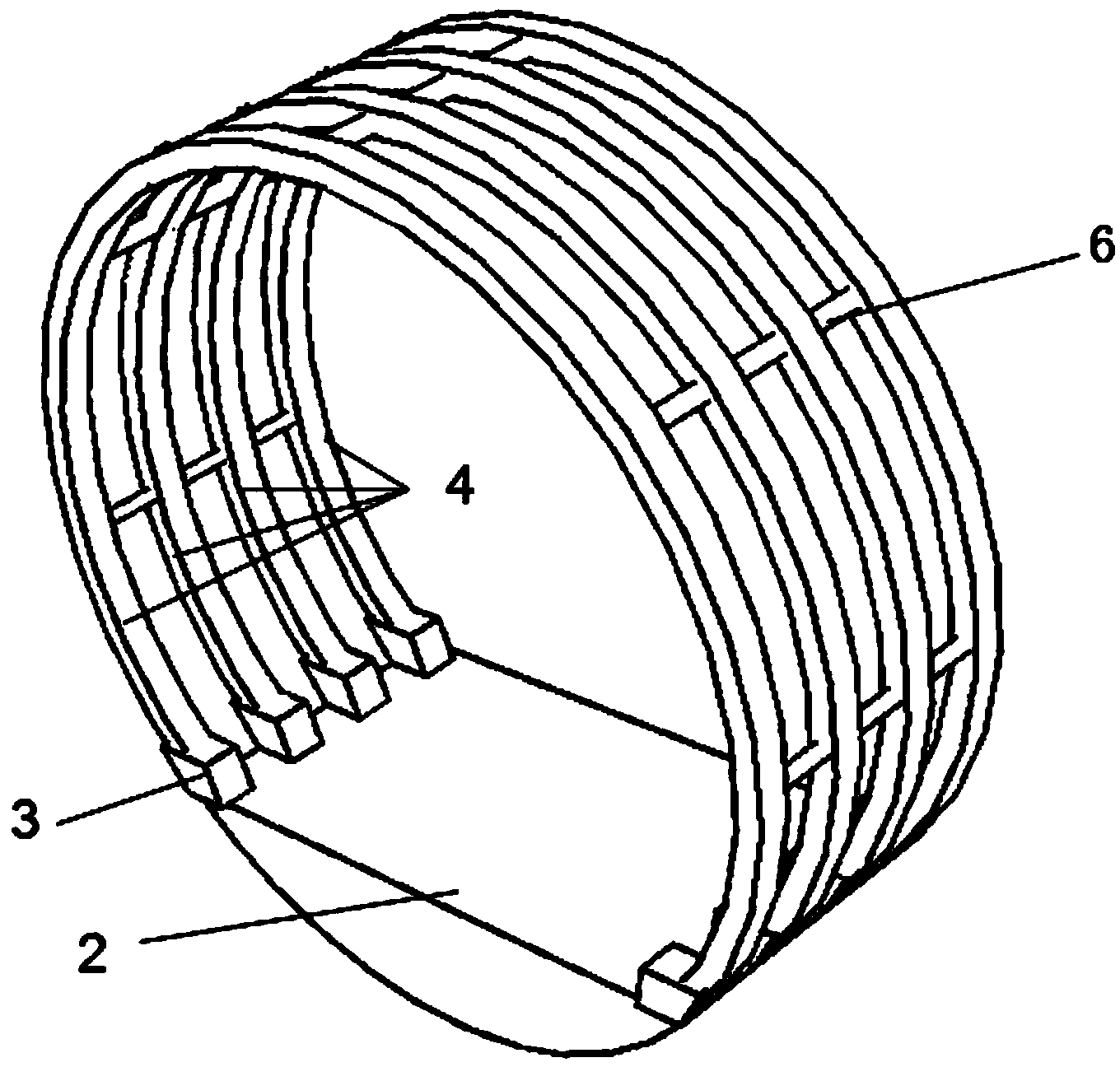

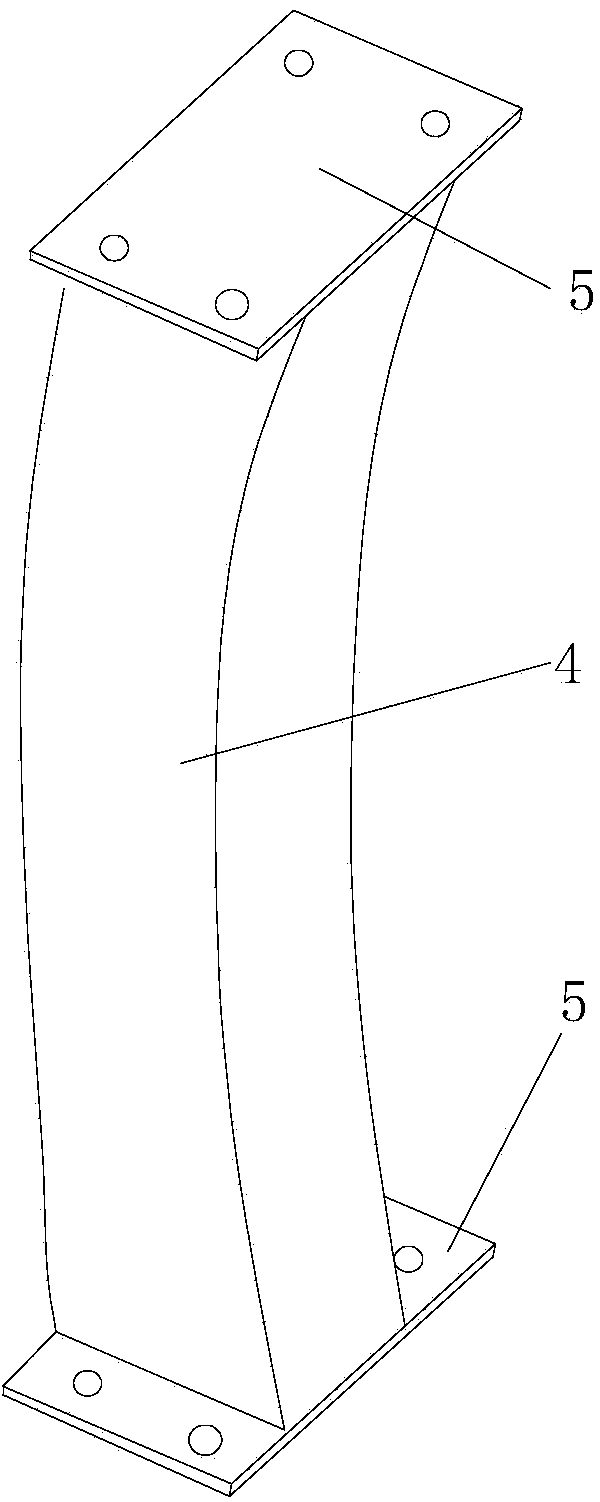

[0034] like Figure 1 to Figure 4 As shown, there is a ballast bed 2 in the tunnel 1. In this embodiment, the radial deformation of the tunnel 1 has occurred, and its maximum value is 20 mm. Utilize arch rings to reinforce the structure of the tunnel, including corbels 3, 500 arch rings and connectors 6 fixed on both sides of the ballast bed 2 of the tunnel 1, and the two ends of the bottom of the arch rings are respectively fixed on the corresponding and corresponding to the arch rings. The corbels 3 on both sides of the ballast bed 2, 500 said arch rings are distributed along the longitudinal direction of the tunnel 1, and at the same time, the two adjacent arch rings are connected by a connecting piece 6;

[0035] The arch ring includes 7 sections of arc-shaped steel pipes 4, the inner cavity of which is filled with concrete, and the cross-section of the arc-shaped steel pipes 4 is square; Tight arch ring. The section size of the arc-shaped steel pipe 4 is 100mm×100mm, wh...

Embodiment 2

[0051] This structure utilizing the arch ring to strengthen the tunnel is the same as embodiment 1 except for the following technical features: in this embodiment, tunnel 1 has undergone radial deformation, and its maximum value is 20mm. Arch rings reinforce it. The arch ring includes 7 sections of arc-shaped steel pipes 4, the inner cavity of the arc-shaped steel pipes 4 is filled with concrete, and the cross-section of the arc-shaped steel pipes 4 is square; The surface of the arch ring 4 is close to the surface, the section size of the arc-shaped steel pipe is 100mm×100mm, and the wall thickness of each side of the arc-shaped steel pipe is 2.5mm.

[0052] Using the finite element software ABAQUS to analyze, if no reinforcement measures are taken for the tunnel, the maximum radial deformation will reach 40 mm, while the maximum radial deformation of the tunnel after the arch ring reinforcement of this embodiment is 30 mm, the maximum radial deformation The deformation reduc...

Embodiment 3

[0054] This structure utilizing the arch ring to strengthen the tunnel is the same as embodiment 1 except for the following technical features: in this embodiment, tunnel 1 has undergone radial deformation, and its maximum value is 20mm. It is reinforced by an arch ring, and the arch ring includes 7 sections of arc-shaped steel pipes 4, the inner cavity of the arc-shaped steel pipes 4 is filled with concrete, and the section of the arc-shaped steel pipes 4 is rectangular; the arc-shaped steel pipes 4 are sequentially Connect to form an arch ring 4 close to the inner wall surface of the tunnel 1, the size of the section of the arc-shaped steel pipe is 80mm×150mm, wherein the section size of the steel pipe along the radial direction of the tunnel 1 is 80mm, and the section size of the steel pipe along the longitudinal direction of the tunnel 1 is 150mm, The wall thickness of each side of the curved steel pipe is 5mm. This embodiment is applicable to the case where there is littl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com