Flexible electrical heating element and manufacturing method thereof

A manufacturing method and flexible technology, which are applied in the field of flexible electric heating heaters and the manufacturing thereof, can solve the problems of pollution of the manufacturing process, reduce the willingness of consumers to purchase, and high cost, so as to reduce the complexity of the manufacturing process and improve the usage. willingness, the effect of optimal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

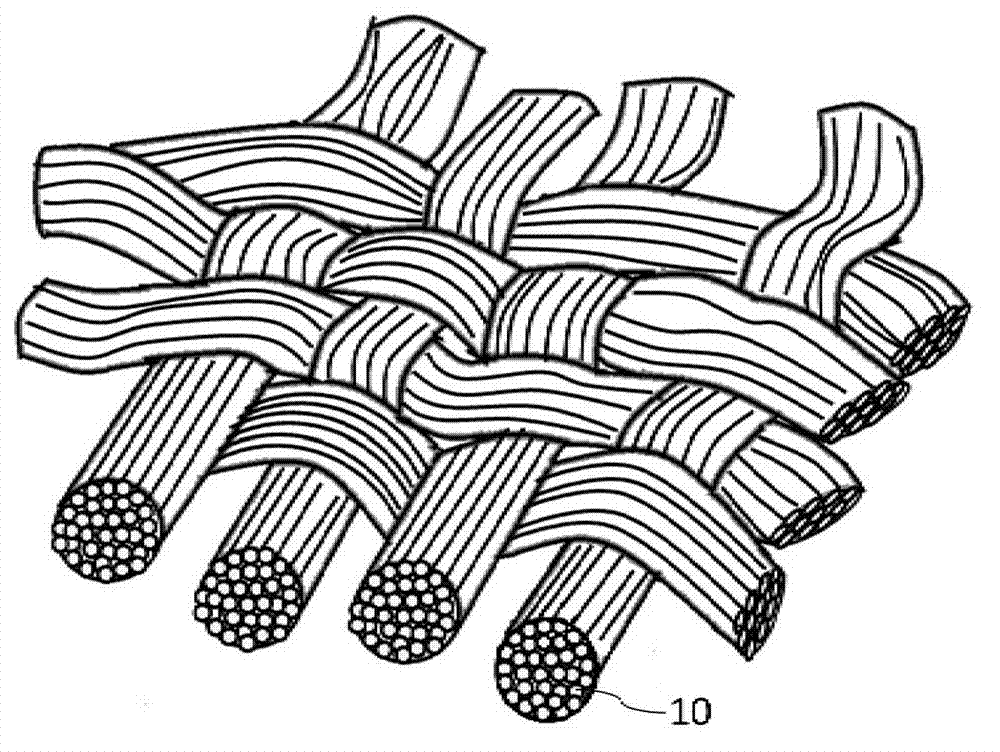

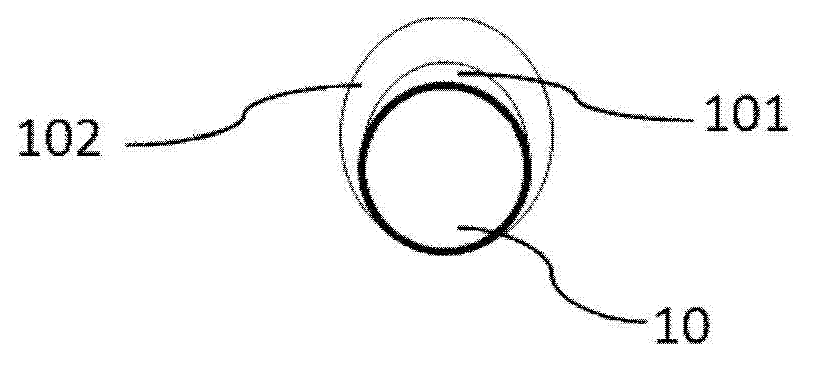

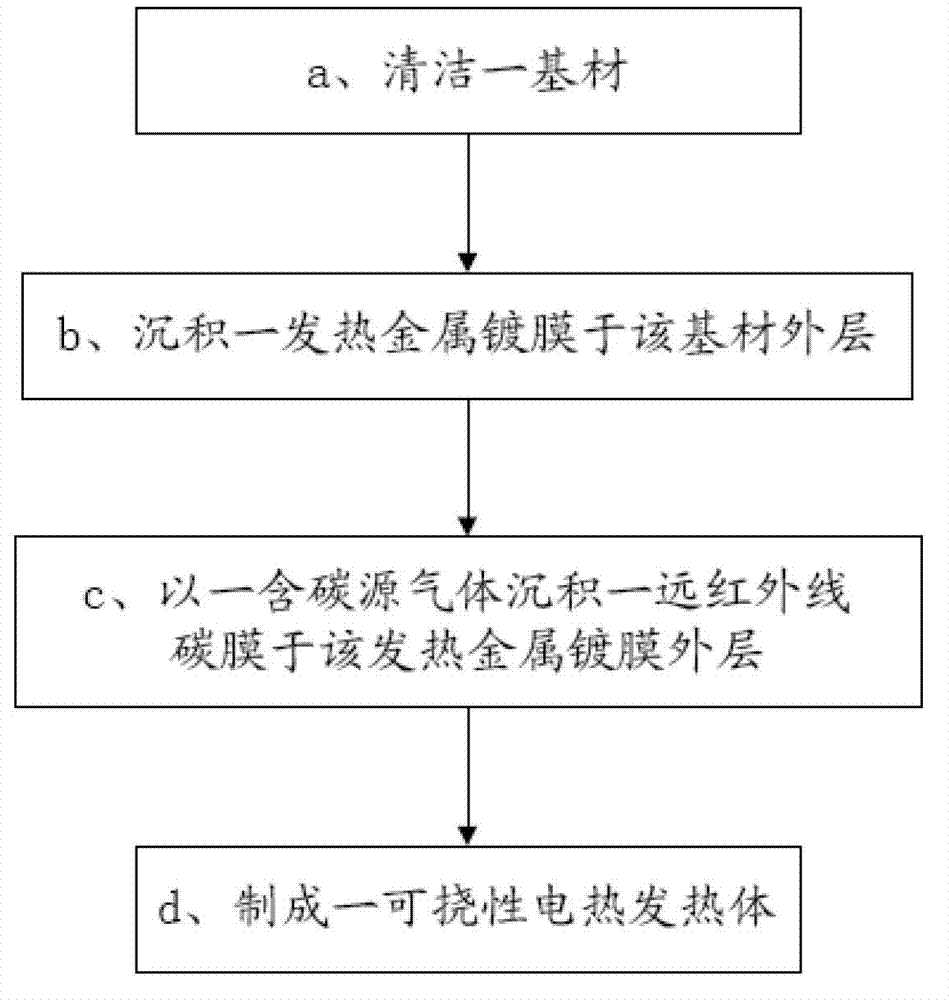

[0018] Please refer to Fig. 1, the flexible electric heating element 1 of the present invention, it comprises a substrate 10, a heating metal coating 101 and a far-infrared carbon film 102, and this heating metal coating 101 and far-infrared ray carbon film 102 with a vacuum coating technology A carbon film 102 is stacked and deposited on the outer layer of the substrate 10 . The base material 10 is an insulating material. The insulating material can be a flexible insulating material such as soft board, fiber bundle, fiber woven cloth or non-woven cloth, and is preferably an insulating material such as polymer fiber cloth or glass fiber cloth. The heat-generating metal coating 101 is used to heat up and generate heat after being electrically connected to the circuit. The metal can be niobium, molybdenum, tantalum, tungsten, rhenium, titanium, vanadium, chromium, zirconium, hafnium, ruthenium, osmium or iridium, etc., suitable for use in vacuum The refractory metals and their a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com