High-Nb-TiAl alloy diffusion bonding method

A technology of diffusion joining and alloying, which is used in welding equipment, metal processing equipment, welding/welding/cutting items, etc. It can solve the problems of complicated diffusion joining process, high diffusion joining temperature, and poor quality of diffusion joining joints, so as to simplify the diffusion joining process. The effect of joining technology, improving quality and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The concrete process of this embodiment is:

[0027] Step 1: Treatment of the connecting surface of the specimen. Use 240#, 400#, 600#, 800#, 1000# and 1500# SiC water sandpaper to polish the surface of the sample in sequence, and use 1.5# diamond grinding paste for mechanical polishing after eliminating obvious scratches on the surface to be connected. The connection surface presents a mirror effect, and then the sample is immersed in absolute ethanol for ultrasonic degreasing treatment for 5 minutes, and stored in absolute ethanol.

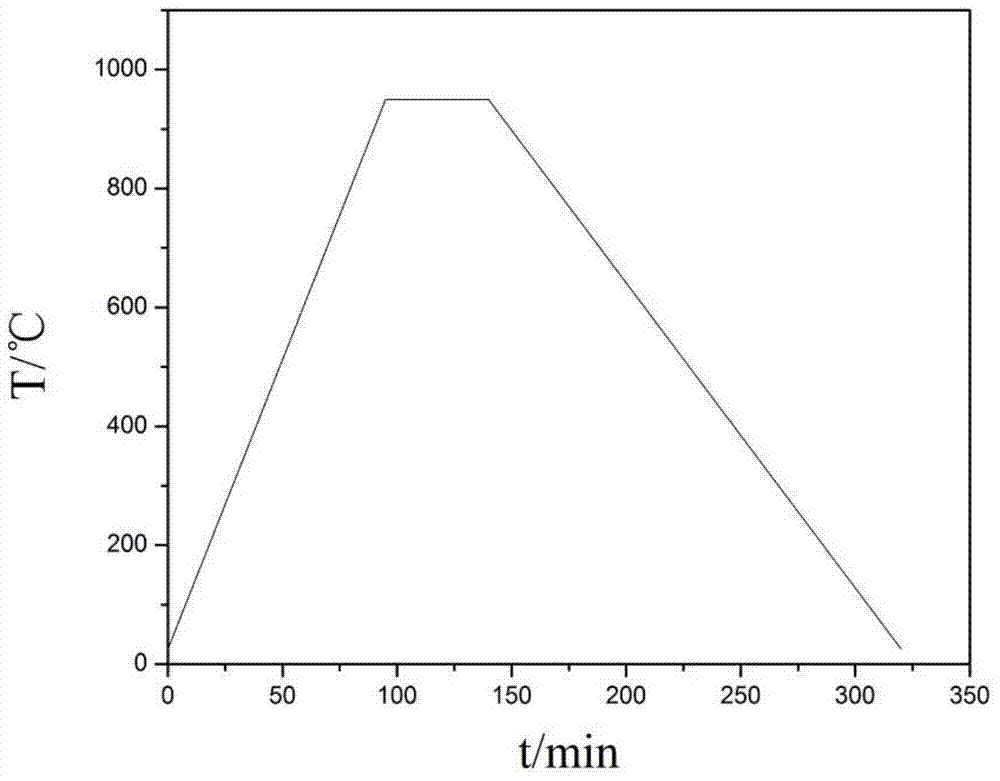

[0028] Step 2: Vacuum diffusion connection. Combine the samples to be connected according to the connection requirements and put them into the vacuum diffusion welding machine for diffusion connection. When implementing diffusion connection, vacuum the chamber of the vacuum diffusion welding machine to 5×10 -3 Pa. The furnace chamber temperature of the vacuum diffusion welding machine was raised to 950°C at a heating rate of 10°C / min....

Embodiment 2

[0033] The concrete process of this embodiment is:

[0034] Step 1: Treatment of the connecting surface of the specimen. Treatment of the surface to be joined of high Nb-TiAl alloy forged samples. Use 240#, 400#, 600#, 800#, 1000# and 1500# SiC water sandpaper to polish the surface of the sample in sequence, and use 1.5# diamond grinding paste for mechanical polishing after eliminating obvious scratches on the surface to be connected. The connection surface presents a mirror effect, and then the sample is immersed in absolute ethanol for ultrasonic degreasing treatment for 5 minutes, and stored in absolute ethanol.

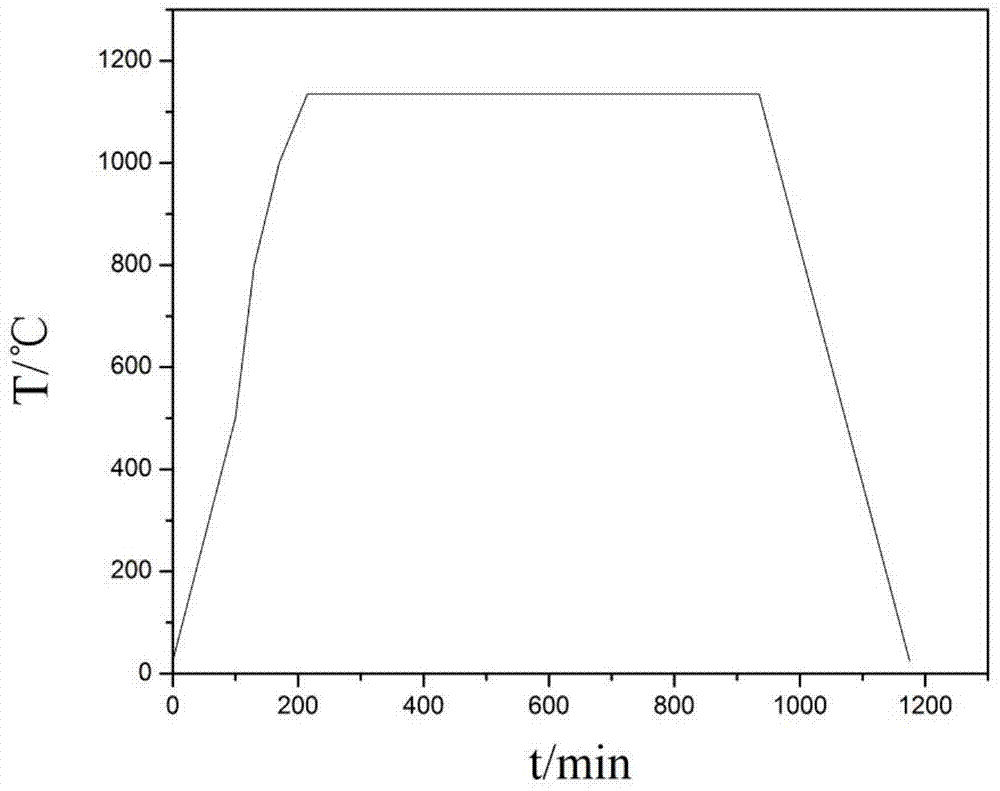

[0035] Step 2: Vacuum diffusion connection. Combine the samples to be connected according to the connection requirements and put them into the vacuum diffusion welding machine for diffusion connection. When implementing diffusion connection, vacuum the chamber of the vacuum diffusion welding machine to 5×10 -3 Pa. The furnace chamber temperature of the vacuum...

Embodiment 3

[0040] The concrete process of this embodiment is:

[0041] Step 1: Treatment of the connecting surface of the specimen. Treatment of the surface to be joined of high Nb-TiAl alloy forged samples. Use 240#, 400#, 600#, 800#, 1000# and 1500# SiC water sandpaper to polish the surface of the sample in sequence, and use 1.5# diamond grinding paste for mechanical polishing after eliminating obvious scratches on the surface to be connected. The connection surface presents a mirror effect, and then the sample is immersed in absolute ethanol for ultrasonic degreasing treatment for 5 minutes, and stored in absolute ethanol.

[0042] Step 2: Vacuum diffusion connection. Combine the samples to be connected according to the connection requirements and put them into the vacuum diffusion welding machine for diffusion connection. When implementing diffusion connection, vacuum the chamber of the vacuum diffusion welding machine to 5×10 -3 Pa. The furnace chamber temperature of the vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com