On-line spc analysis system and method for measuring process capability of weighing filling equipment

A filling equipment and process capability technology, applied in the field of automatic collection and analysis, can solve the problems of large metering risks, inability to take measures in time, control difficulties, etc., to eliminate the risk of tare average value, reduce the risk of metering process, application promising effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

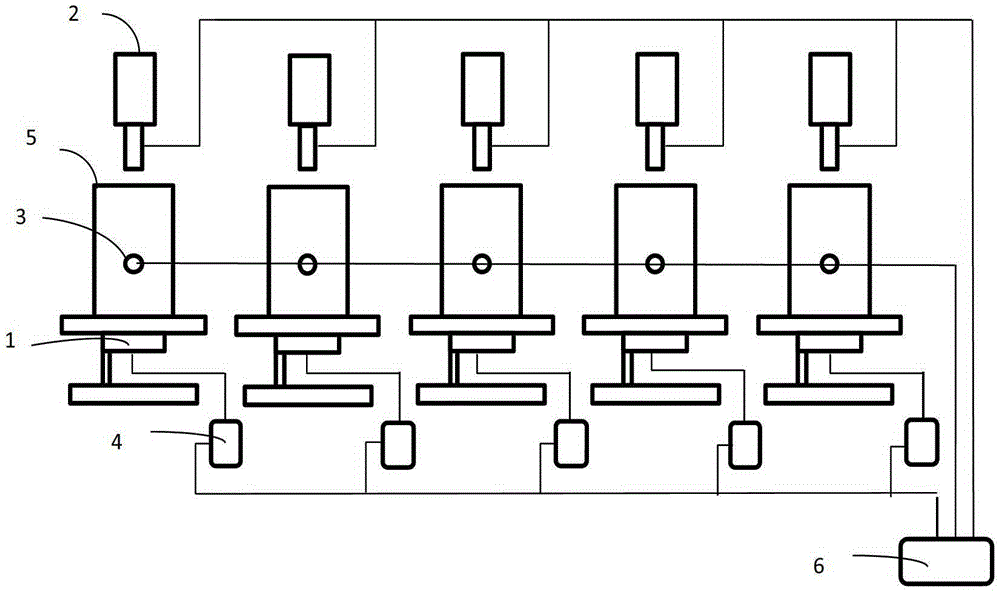

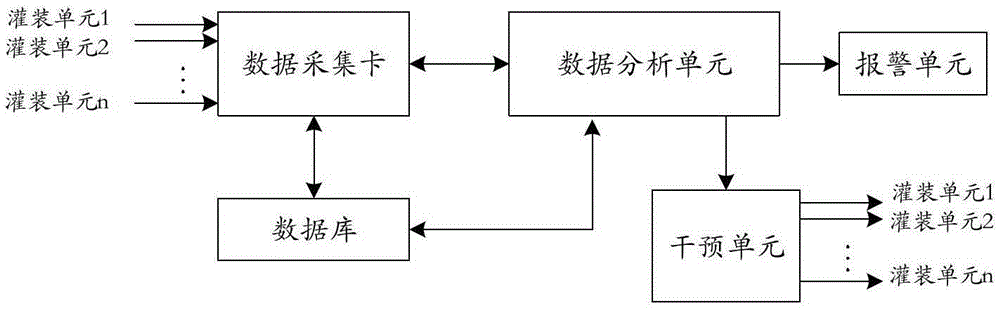

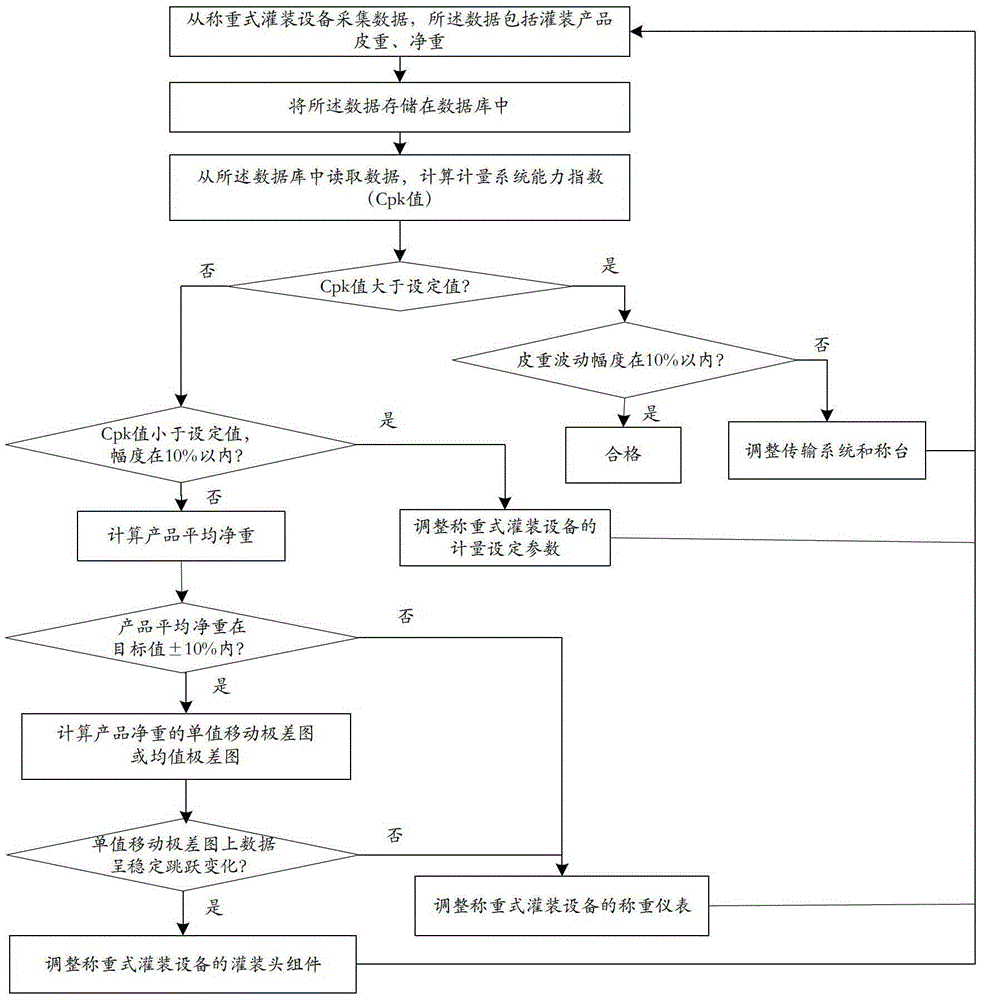

[0022] The invention provides an online SPC analysis system for measuring process capability of weighing filling equipment, its structure is as follows figure 2 shown. The system includes a data acquisition card for collecting data of weighing filling equipment, a database for storing data, and a data analysis unit for analyzing the data.

[0023] Wherein, the data acquisition card is connected with the weighing filling equipment to be analyzed, specifically, with the measuring instrument of each filling unit (such as filling head) of the weighing filling equipment. The connection mode between the data acquisition card and the measuring instrument can be serial port (RS232), parallel port (RS485), infrared, Bluetooth, network port, GSM, GPRS, 3G, etc., depending on the communication port and hardware structure of the measuring instrument. During the continuous operation of the weighing filling equipment, the data acquisition card collects the tare weight and net weight data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com