Two-degree-of-freedom double-closed-loop hybrid drive reach-stack crane

A hybrid drive, double closed-loop technology, used in cranes and other directions, can solve the problems of high processing and assembly requirements, high maintenance costs, and poor dynamic performance of hydraulic system components, and achieve high processing and assembly requirements, low maintenance costs, and low maintenance costs. The effect of low cost of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

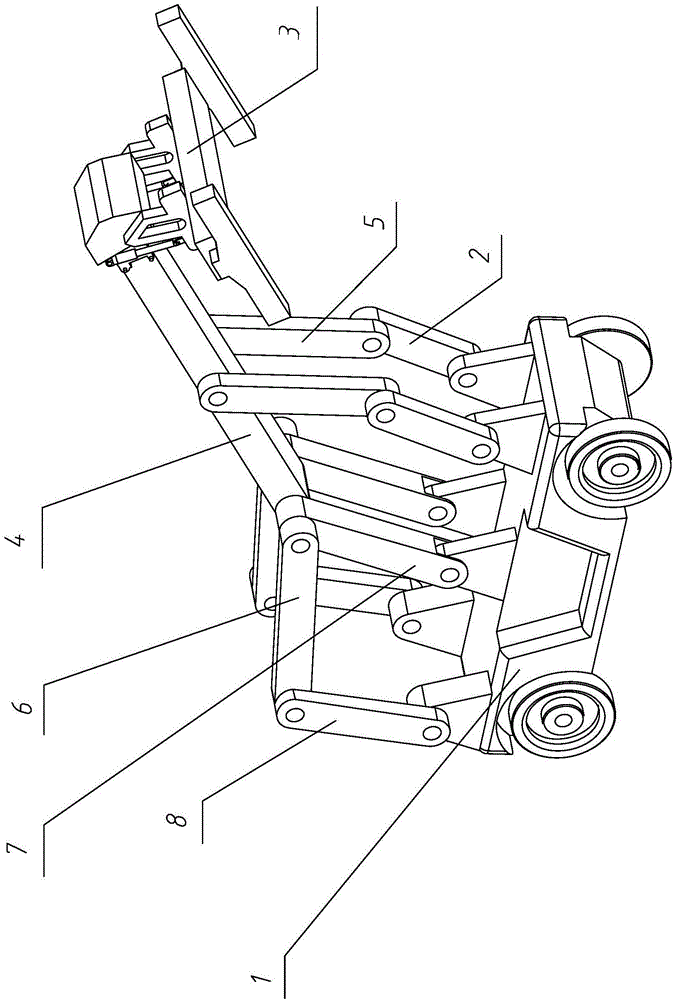

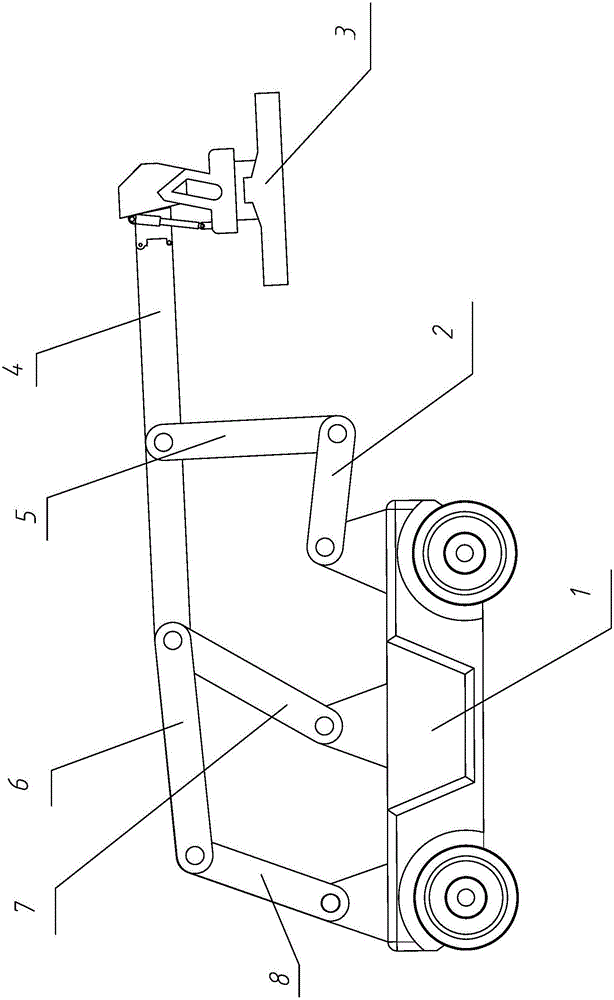

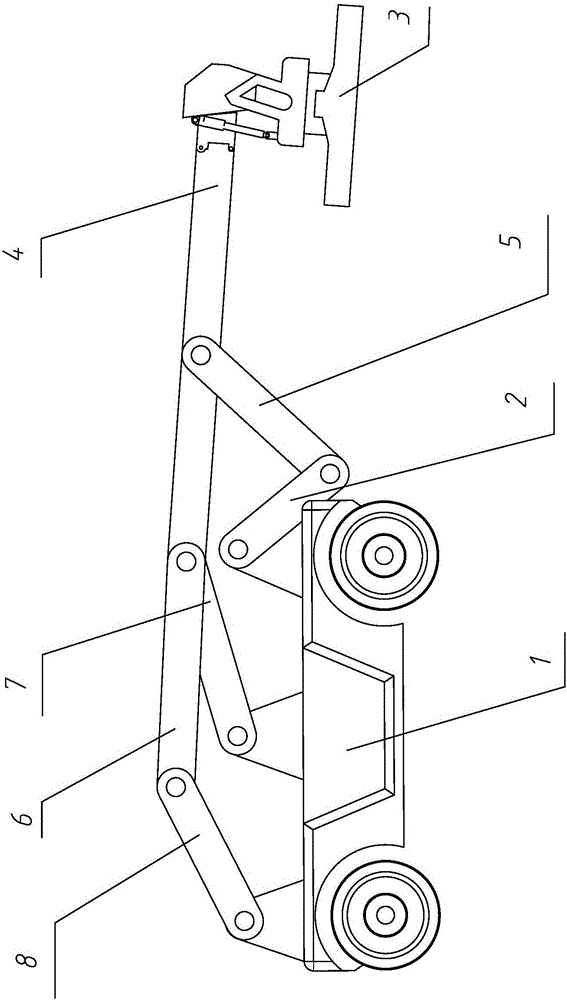

[0016] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0017] The two-degree-of-freedom double-closed-loop hybrid drive reach stacker of the present invention includes a boom, a boom lifting mechanism, and a boom telescoping mechanism arranged on the basis of the vehicle frame 1, forming a double-closed-loop chain motion mechanism.

[0018] Described boom comprises pitch arm 7 and swing arm 4, and the lower end of described pitch arm 7 is hinged at the middle part of vehicle frame 1, and the rear end of described swing arm 4 is hinged with the upper end of pitch arm 7, and the upper end of swing arm 4 The front end is provided with a clamping device 3, such as figure 1 shown.

[0019] The boom elevating mechanism is located in front of the boom, and includes lifting rockers 2 and lifting connecting rods 5 symmetrically arranged on both sides of the boom. The upper end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com