A method for producing 4a zeolite by using waste alumina and quartz sand

A technology of alumina and quartz sand, applied in the direction of crystalline aluminosilicate zeolite, A-type crystalline aluminosilicate zeolite, etc., can solve the problems of high energy consumption, high raw material cost, and large impact of raw material market fluctuations, so as to reduce evaporation load, reduce production costs, and avoid transportation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

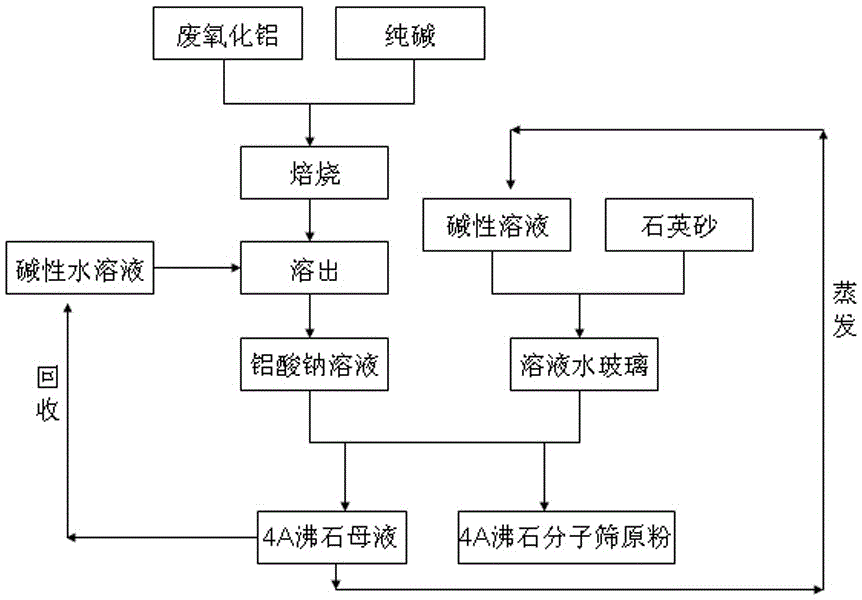

Method used

Image

Examples

Embodiment 1

[0025] Preparation of Part1 Sodium Aluminate Solution

[0026] Take the waste alumina in the alumina industry, and it mainly contains the following components after testing: 82%Al 2 o 3 , 5% silica, 5% calcium oxide and 2% iron, according to Al in alumina waste 2 o 3 content, according to Na 2 O, Al 2 o 3 Add soda ash at a molar ratio of 1.15, mix well, and bake at 950°C through a rotary kiln. The roasting time is controlled at 0.5h by the number of rotations of the rotary kiln and the amount of material to be fed, and the roasted material is used with Na 2 O concentration is the stripping of 75g / L alkaline aqueous solution, makes the Na in the whole solution 2 O / Al 2 o 3 The molar ratio is 2 to obtain a sodium aluminate solution.

[0027] Preparation of Part2 liquid water glass

[0028] 4A zeolite dilute mother liquor is evaporated to make Na 2 The O concentration reaches 3.5mol / l, according to the Na of the evaporated mother liquor 2 O concentration, the additio...

Embodiment 2

[0033] Preparation of Part1 Sodium Aluminate Solution

[0034] Take the waste alumina in the alumina industry, and it mainly contains the following components after testing: 82%Al 2 o 3 , 5% silica, 5% calcium oxide and 2% iron, according to Al in alumina waste 2 o 3 content, according to Na 2 O, Al 2 o 3 Add soda ash at a molar ratio of 1.0, mix well, and roast at 1000°C through a rotary kiln. The roasting time is controlled at 0.3h by the number of revolutions of the rotary kiln and the amount of feeding, and the roasted materials are used with Na 2 O concentration is the stripping of 50g / L alkaline aqueous solution, makes Na in the whole solution 2 O / Al 2 o 3 The molar ratio was 1.5 to obtain a sodium aluminate solution.

[0035] Preparation of Part2 liquid water glass

[0036] 4A zeolite dilute mother liquor is evaporated to make Na 2 The O concentration reaches 3mol / l, according to the Na of the evaporated mother liquor 2 O concentration, the amount of quartz...

Embodiment 3

[0041] Preparation of Part1 Sodium Aluminate Solution

[0042] Take the waste alumina in the alumina industry, and it mainly contains the following components after testing: 82%Al 2 o 3 , 5% silica, 5% calcium oxide and 2% iron, according to Al in alumina waste 2 o 3 content, according to Na 2 O, Al 2 o 3 Add soda ash at a molar ratio of 1.5, mix well, and bake at 800°C through a rotary kiln. The roasting time is controlled within 1h by the number of revolutions of the rotary kiln and the amount of feeding, and the roasted materials are used with Na 2 O concentration is 100g / L the stripping of alkaline aqueous solution, makes the Na in the whole solution 2 O / Al 2 o 3 The molar ratio is 2 to obtain a sodium aluminate solution.

[0043] Preparation of Part2 liquid water glass

[0044] 4A zeolite dilute mother liquor is evaporated to make Na 2 The O concentration reaches 5mol / l, according to the Na of the evaporated mother liquor 2 O concentration, the addition amoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com