A kind of continuous oxidation method for preparing hexanoic acid by oxidizing sec-octanol with nitric acid

A technology of nitric acid oxidation and sec-octanol, applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of low oxidation efficiency, time-consuming and energy-consuming, and potential safety hazards, so as to improve production Efficiency, reduce warm-up response time, save power and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

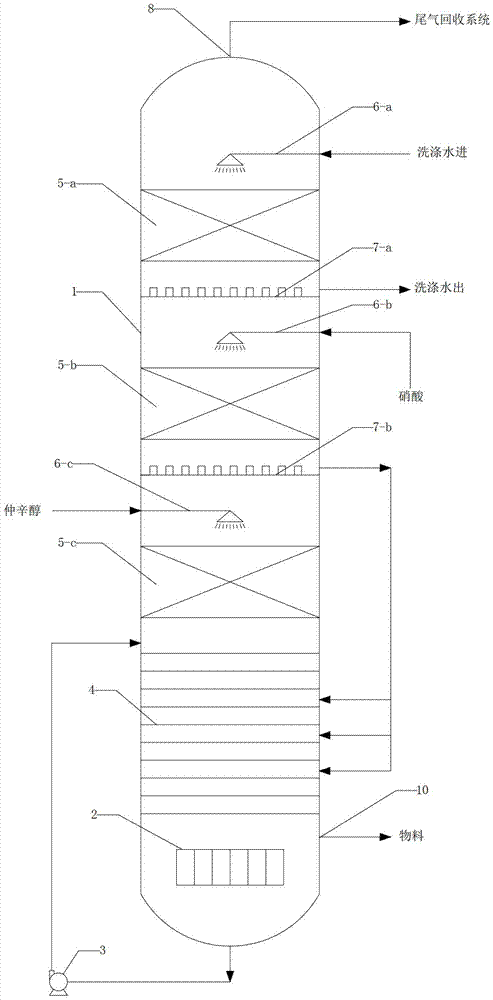

[0026] Such as figure 1 As shown, in a mixing tower body 1 with a diameter of 1000 mm, a heating device 2 and a material circulation pump 3 are installed at the bottom of the tower, and 10 bubble-cap plates 4 are installed in the lower half of the tower (from top to bottom are the 1st to 10th plates), The upper half of the tower is equipped with upper, middle and lower packing layers respectively, corresponding to packing layer 5-a, packing layer 5-b and packing layer 5-c respectively, packing layer 5-a, packing layer 5-b and The upper part of the packing layer 5-c is respectively provided with a liquid spray pipe 6-a, a spray pipe 6-b and a spray pipe 6-c, and the lower part of the packing layer 5-a and the packing layer 5-b is respectively provided with a liquid collecting plate 7 -a, the liquid collecting plate 7-b, the uppermost part of the mixing tower is provided with an exhaust gas outlet 8, which is connected with the exhaust gas recovery system, and the lowermost part...

Embodiment 2

[0028] In this embodiment, a packed tower is used, that is, the 10-plate blister plate in the lower half of the tower in Example 1 is converted into 14 packing layers, and the entire packed tower is 17 packing layers (from top to bottom 1-17). The specific process is as follows : Use a pump to add the 2-octanol mixed with the catalyst to the third section of the packing layer through the spray pipe, directly flow into the fourth and fifth sections of the packing layer until the bottom of the tower, stop feeding when the material circulation pump can circulate, and turn on the heating device to When the temperature in the tower rises to 90°C, use a pump to add 40% nitric acid into the second packing layer through the spray pipe, continue heating and material circulation, and when the temperature is maintained at 100°C and yellow smoke comes out from the top of the tower, the reaction proceeds normally. , stop heating; at the same time, add 2-octanol mixed with catalyst at a flow...

Embodiment 3

[0030]This embodiment adopts a plate tower, that is, the three-stage packing layer in the upper half of the tower in Example 1 is converted into an 8-plate blister plate, and three spray pipes are respectively arranged on the top of the 1st, 5th, and 7th plates of the blister plate. The liquid collecting plates are respectively arranged at the lower part of the 4th and 6th plates of the blister plate, and the specific process is as follows: the secondary octanol mixed with the catalyst is added to the 7th plate of the blister plate through the spray pipe through the pump, and directly flows into the blister plate From the 8th and 9th plates to the bottom of the tower, stop feeding when the material circulation pump can circulate, turn on the heating device until the temperature in the tower rises to 110°C, use a pump to add 40% nitric acid to the fifth plate of the blister plate through the spray pipe, Continue heating and material circulation, and stop heating when the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com