Method for preparing heat and salinity tolerance filtrate reducer from waste polystyrene foam

A technology of waste polystyrene and fluid loss control agent, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems that have not been reported before, achieve excellent salt resistance, eliminate white pollution, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

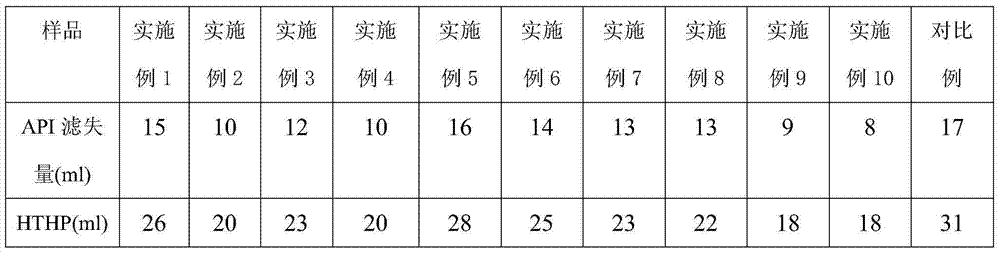

Examples

Embodiment 1

[0034] A method for preparing a temperature-resistant and salt-resistant fluid loss reducer by using waste polystyrene foam, the steps are as follows:

[0035] (1) Add 50g of waste polystyrene foam crushed to 5mm into the reaction bottle;

[0036] (2) Pour 150ml of methyl ethyl ketone liquid into the above reaction bottle, stir and dissolve, then raise the temperature to 40°C; 3 Gas (40ml / min) for 120min, then stop the ventilation and cool down to room temperature to obtain the waste polystyrene foam modified mixture;

[0037] (3) adjust the pH=9 of the waste polystyrene foam modified mixture obtained in step (2) with 20wt% NaOH solution;

[0038] (4) Move the solution in step (3) into a vacuum distillation device, and distill at 85°C for 1h at a vacuum of -0.5kPa; dry the product obtained by removing the solvent at 105°C for 10h, and crush it to 40 meshes. That is the product.

Embodiment 2

[0040] A method for preparing a temperature-resistant and salt-resistant fluid loss reducer by using waste polystyrene foam, the steps are as follows:

[0041] (1) Add 50g of polystyrene foam waste crushed to 5mm into the reaction bottle;

[0042] (2) Pour 150ml methyl ethyl ketone aqueous solution (methyl ethyl ketone: water mass ratio is 40:1) into the above reaction bottle, stir and dissolve, then raise the temperature to 40°C; pass SO into the above solution 3 Gas (40ml / min) for 120min, then stop the ventilation and cool down to room temperature to obtain the waste polystyrene foam modified mixture;

[0043] (3) adjust the pH=8 of the waste polystyrene foam modified mixture obtained in step (2) with 20wt% NaOH solution;

[0044] (4) Move the solution in step (3) into a vacuum distillation device, and distill at 85°C for 1h at a vacuum of -0.5kPa; dry the obtained solvent-removed product at 105°C for 10h, crush it to 60 mesh, That is the product.

Embodiment 3

[0046] A method for preparing a temperature-resistant and salt-resistant fluid loss reducer by using waste polystyrene foam, the steps are the same as in Example 1, the difference is that in step (2), SO 3 The gas time is 80 minutes; in step (3), adjust the pH of the waste polystyrene foam modified mixture obtained in step (2) to 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com