Polyethylene/eucalyptus wood powder composite material, and preparation method thereof

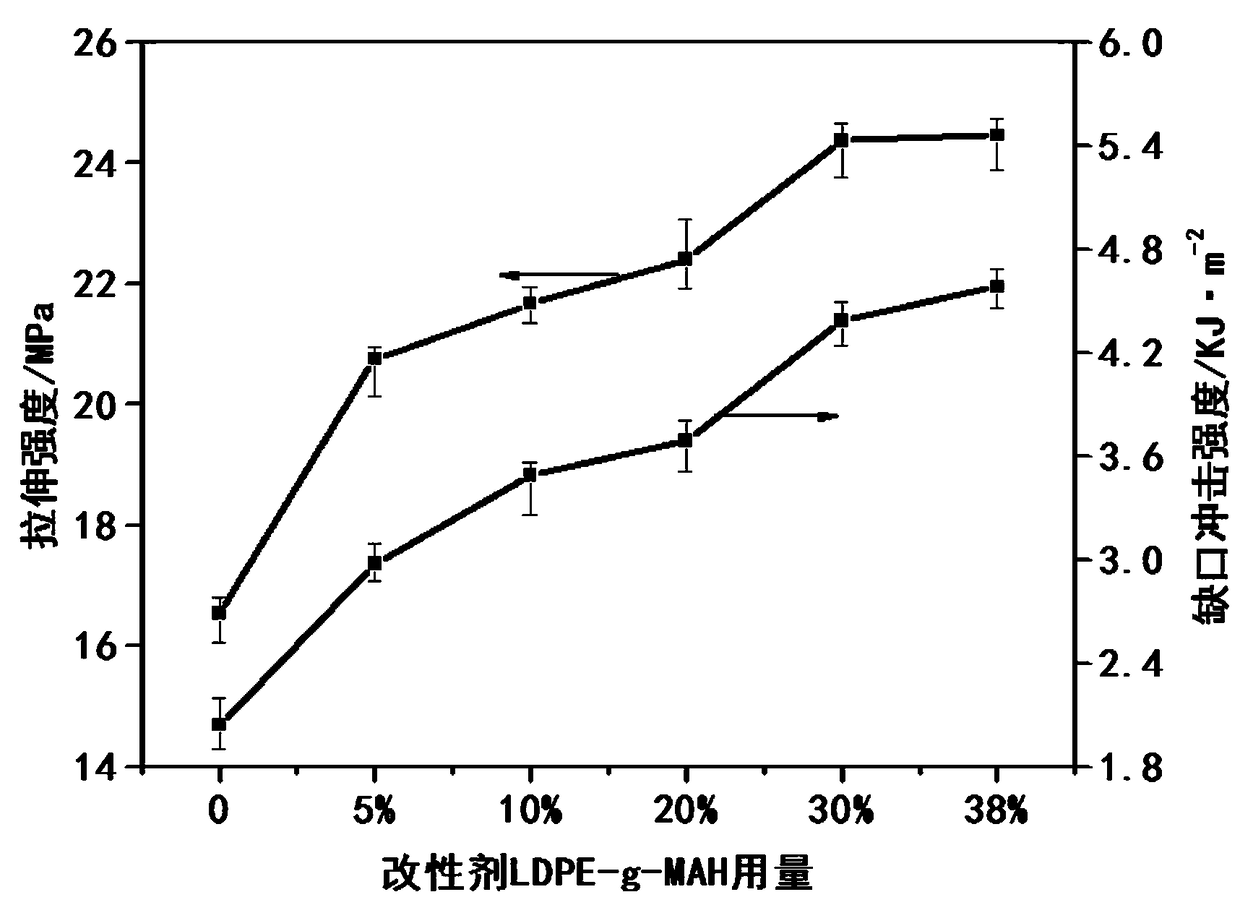

A technology of composite material and eucalyptus powder, which is applied in the field of polyethylene/eucalyptus powder composite material and its preparation, can solve the problem of no high value-added utilization of eucalyptus powder, and achieve the improvement of mechanical properties, compatibility, and The effect of interfacial bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A polyethylene / eucalyptus powder composite material, the composition of the composite material by weight percentage content includes: dry eucalyptus powder 60%; recycled polyethylene 33%; LDPE-g-MAH modifier 5%; paraffin 0.3%; 0.7% polymer wax; 0.5% calcium stearate and 0.5% lead stearate; the dry eucalyptus wood powder is 60-80 mesh in fineness and dried at 120°C until the moisture weight percentage is ≤2% Dry eucalyptus wood powder; the LDPE-g-MAH modifier is a self-made high grafting rate low density polyethylene grafted maleic anhydride, and the grafting rate is not less than 1.3%; the reclaimed polyethylene is reclaimed After the high-quality LDPE plastic is cleaned, crushed, dried and granulated, it is made into pellets with a moisture content of ≤0.5% and a particle size of less than 12mm.

[0038] The preparation method of described polyethylene / eucalyptus powder composite material, comprises the following steps:

[0039] (1) Take various raw materials accordin...

Embodiment 2

[0042]A polyethylene / eucalyptus powder composite material, the composition of the composite material by weight percentage content includes: dry eucalyptus powder 65%; recycled polyethylene 25%; LDPE-g-MAH modifier 8%; paraffin 0.4%; 0.6% polymer wax; 0.5% calcium stearate and 0.5% lead stearate; the dry eucalyptus wood powder is 80-100 mesh in fineness and dried at 160°C until the moisture weight percentage is ≤2% dry eucalyptus wood powder; the LDPE-g-MAH modifier is high grafting rate low density polyethylene grafted maleic anhydride, the grafting rate is not less than 1.3%; the reclaimed polyethylene will be reclaimed After washing, crushing, drying, and granulation, PE plastics are made into pellets with a moisture content of ≤0.5% and a particle size of less than 12mm.

[0043] The preparation method of described polyethylene / eucalyptus powder composite material, comprises the following steps:

[0044] (1) Take various raw materials according to the weight percentage con...

Embodiment 3

[0047] A polyethylene / eucalyptus powder composite material, the composition of the composite material by weight percentage content includes: dry eucalyptus powder 65%; recycled polyethylene 23%; LDPE-g-MAH modifier 10%; paraffin 0.3%; 1.0% polymer wax; 0.1% calcium stearate and 0.6% lead stearate; the dry eucalyptus wood powder has a fineness of 100-120 mesh and is dried at 140°C until the moisture weight percentage is ≤2%. Dry eucalyptus wood powder; the LDPE-g-MAH modifier is a self-made high grafting rate low density polyethylene grafted maleic anhydride, and the grafting rate is not less than 1.3%; the reclaimed polyethylene is reclaimed After the high-quality HDPE plastic is cleaned, crushed, dried, and granulated, it is made into pellets with a moisture content of ≤0.5% and a particle size of less than 12mm.

[0048] The preparation method of described polyethylene / eucalyptus powder composite material, comprises the following steps:

[0049] (1) Take various raw materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com