Low-apparent-viscosity polyamide acid solution and preparation method thereof

A polyamic acid and apparent viscosity technology, which is applied in the field of low apparent viscosity polyamic acid solution and its preparation, can solve the problems of increased solvent consumption, low viscosity efficiency, many process steps, etc. The effect of reducing apparent viscosity and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

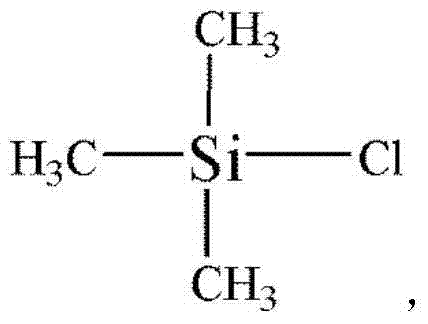

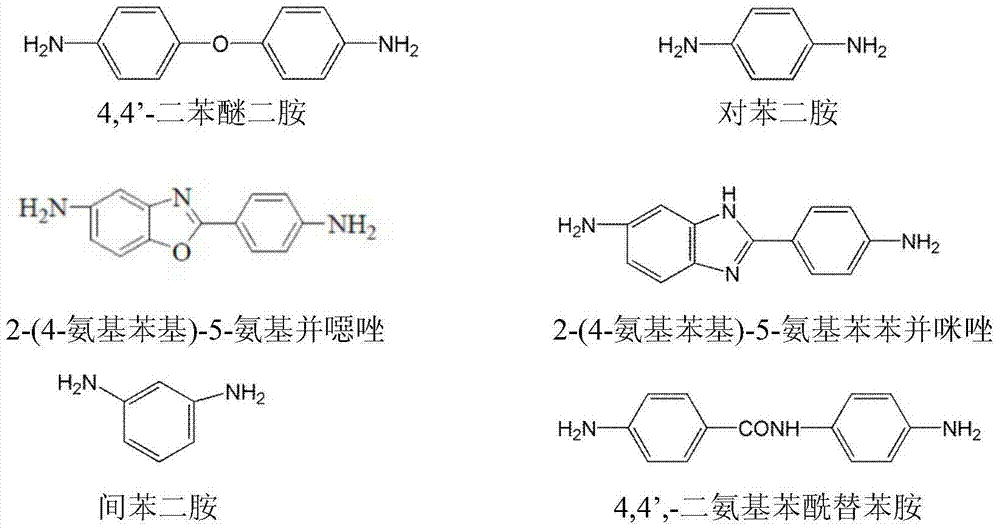

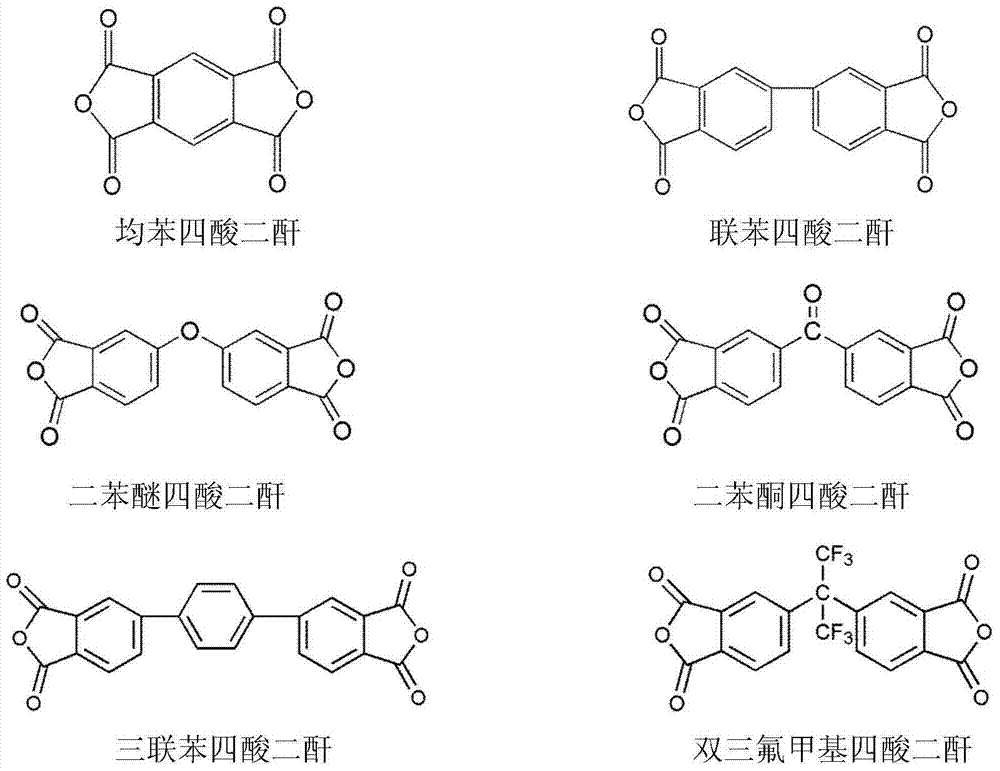

[0033] Under a nitrogen atmosphere, first dissolve 15.9490g ODA in 300g N-methylpyrrolidone, then quickly add 17.3844g PMDA, and stir at room temperature for 3 hours to obtain a polyamide with a solid content of 10% and an apparent viscosity of 450,000 centipoise acid solution, then add trimethylchlorosilane with 30% polyamic acid mass to the obtained polyamic acid solution, and stir at room temperature for 3 hours to obtain a polyamic acid solution with an apparent viscosity of 9,000 centipoise, and then press Thermal imidization in conventional manner.

Embodiment 2

[0035] According to the method of Example 1, using PDA and BPDA with a molar ratio of 1:1, and using N,N'-dimethylacetamide as a solvent, a polymer with a solid content of 12% and an apparent viscosity of 850,000 centipoises was prepared. Amic acid solution. Then, trimethylchlorosilane with 40% polyamic acid mass was added to the obtained polyamic acid solution, and stirred at room temperature for 5 hours to obtain a polyamic acid solution with an apparent viscosity of 15,000 centipoise, and then heat acyl chloride in a conventional manner. imidization.

Embodiment 3

[0037] According to the method of Example 1, using MDA and OPDA with a molar ratio of 1:1, and using N,N'-dimethylformamide as a solvent, a polymer with a solid content of 20% and an apparent viscosity of 100,000 centipoise was prepared. Amic acid solution. Then, trimethylchlorosilane with 20% polyamic acid mass was added to the obtained polyamic acid solution, stirred at room temperature for 1 hour to obtain a polyamic acid solution with an apparent viscosity of 10,000 centipoise, and then heated in a conventional manner. imidization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com