Hydrofining method for heavy benzene

A technology for hydrofining and heavy benzene, which is applied in hydrotreating process, petroleum industry, hydrocarbon oil treatment, etc. It can solve the problem of high temperature rise in the pre-hydrofining reaction zone, and achieve stable and safe operation and save equipment The effect of investment and extended operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

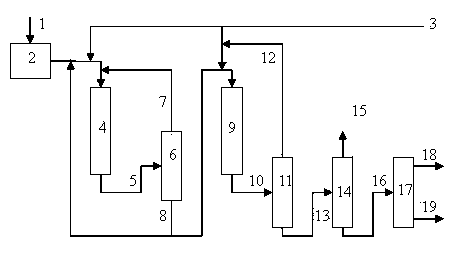

[0030] The properties of the heavy benzene raw materials used are shown in Table 1, and the specific process flow is shown in figure 1 .

Embodiment 1

[0031] In Example 1 and Example 3, the pre-hydrofinishing reaction zone is filled with hydrofinishing catalyst FF-26, and the main hydrogenation reaction zone is filled with hydrogenation protection catalyst FZC-103 and hydrofinishing catalyst 3936 in sequence from top to bottom. The loading volume ratio of the catalyst is 1:7; in Example 2, the pre-hydrofinishing reaction zone is filled with hydrofinishing catalyst 3936, and the main hydrogenation reaction zone is sequentially filled with hydrogenation protection catalyst FZC-103 and hydrogenation catalyst FZC-103 from top to bottom. Refining catalyst FF-26, the loading volume ratio of the two catalysts is 1:5.

[0032] In Examples 1-3, after the gas-liquid separation of the pre-hydrofining oil, the separated liquid phase product is recycled to the pre-hydrofining reaction zone to be mixed with heavy benzene as the raw material. The circulation weight ratio of the pre-hydrofining oil to heavy benzene in Examples 1 and 2 is 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com