Reinforcement type prefabricated assembly type shear wall structure and construction method thereof

A prefabricated assembly and shear wall technology, which is applied in the direction of walls, building components, building structures, etc., can solve the problems that the strength of the vertically distributed steel bars in the wall is not fully exerted, the prefabricated shear walls lack support, and the seismic ductility of components is weakened. , to achieve the effect of simple and easy construction, convenient on-site construction, and improved shear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

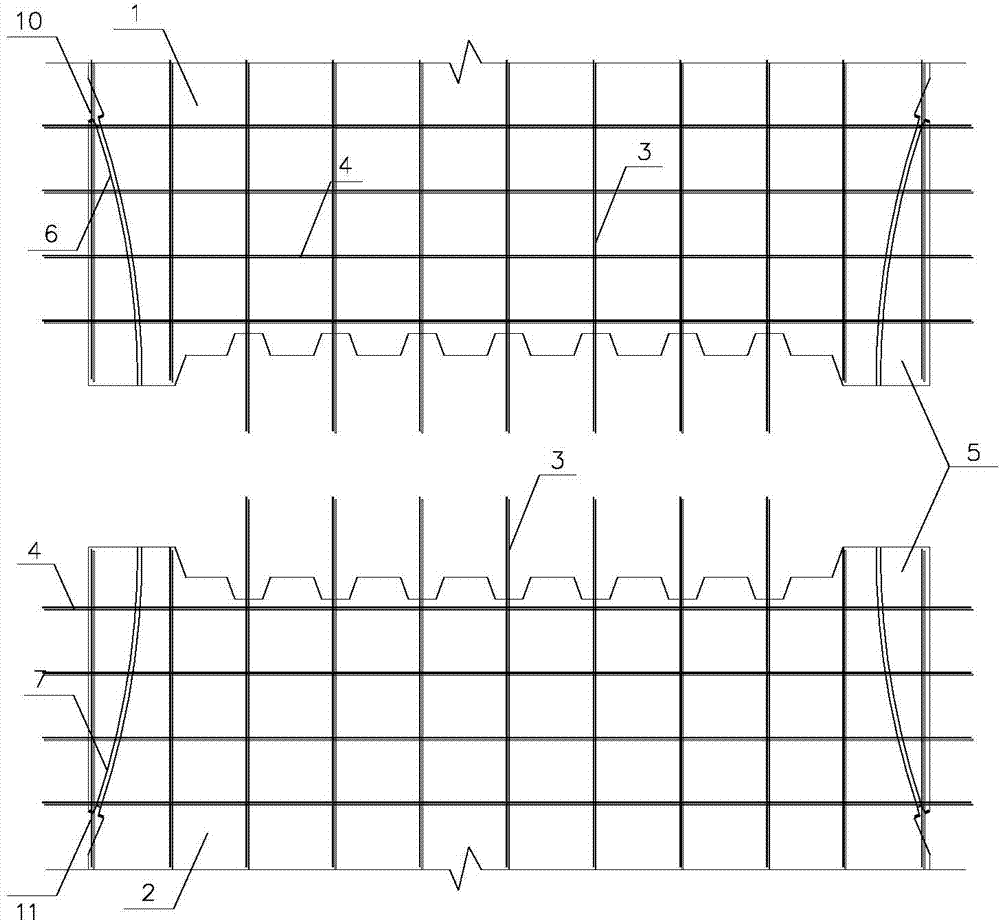

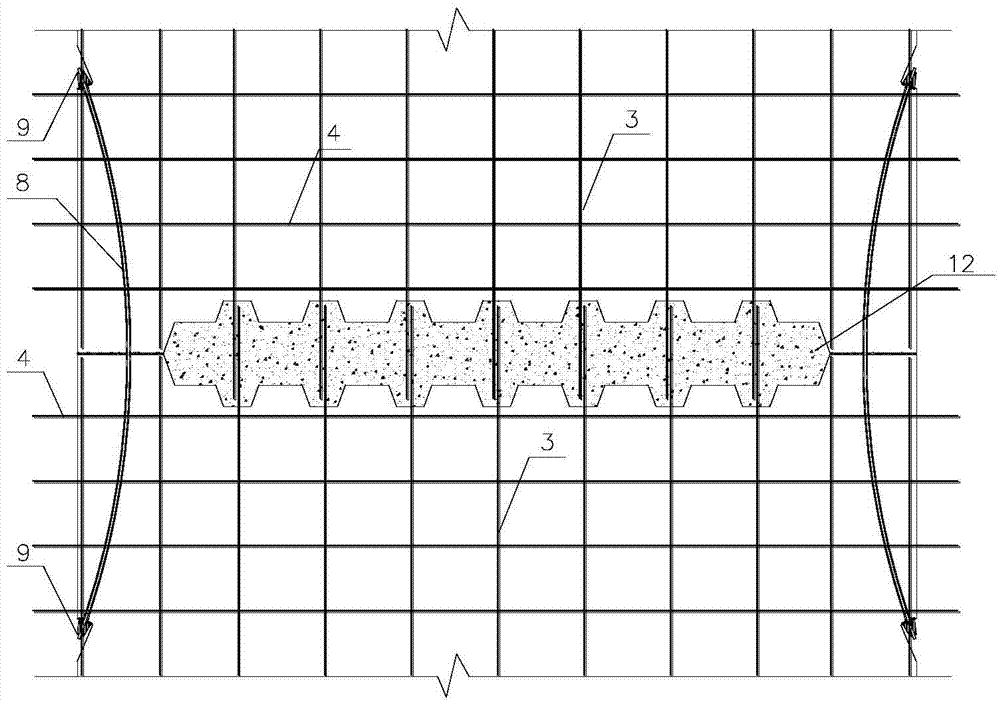

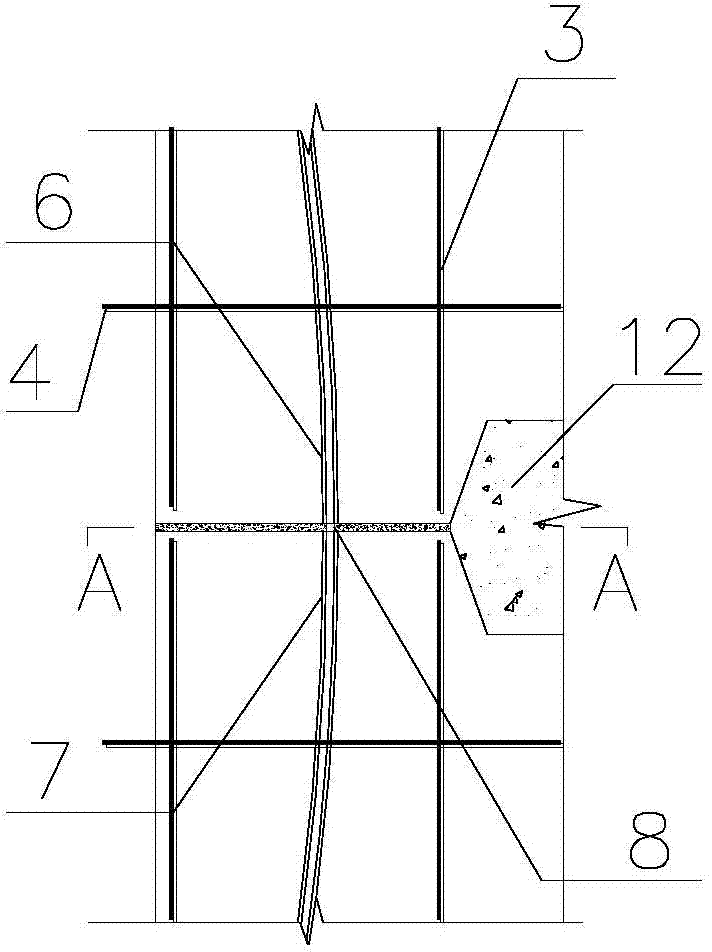

[0032] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0033] see Figure 1 to Figure 8 , a reinforced prefabricated prefabricated shear wall structure, prestressed steel beams 8 run through the adjacently connected upper prefabricated wall 1 and lower prefabricated wall 2 .

[0034]In this embodiment, according to the connection strength requirements between the upper prefabricated wall 1 and the lower prefabricated wall 2, a There is a prestressed steel beam 8. In order to facilitate the anchoring construction of the prestressed steel beam 8, the above-mentioned prestressed steel beam 8 is arc-shaped, and the upper end of the prestressed steel beam 8 is anchored on one side of the upper prefabricated wall 1. The lower end of the bundle 8 is anchored to one side of the lower prefabricated wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com