Miniature implanted type ultrasonic resonance wireless energy transfer receiver and manufacturing method thereof

A technology of wireless energy and ultrasonic transducers, applied in the direction of microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problems of adverse effects on human tissue, large volume of piezoelectric materials, and high requirements for ultrasonic pressure, and achieve the realization of Effect of long-term stable energy supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

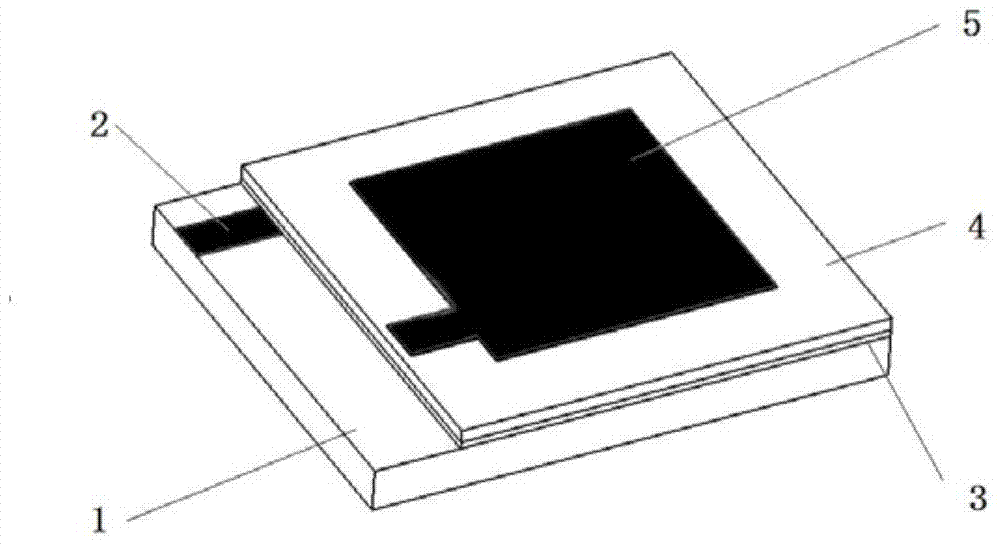

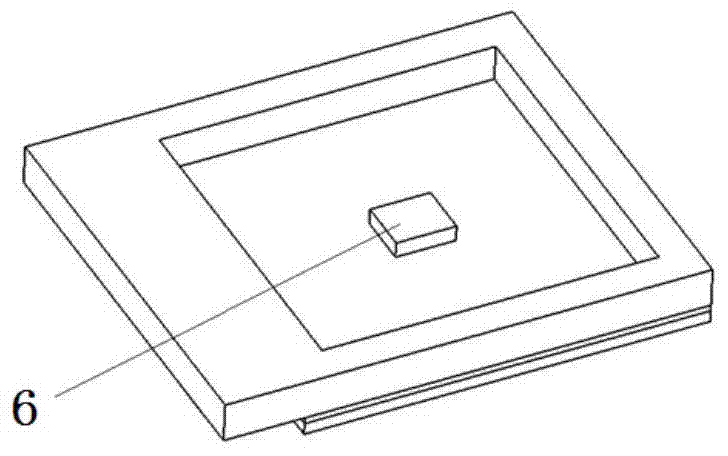

[0058] Such as figure 1 , 2 , 3, in this embodiment, the ultrasonic transducer module 8 is a rectangular piezoelectric material 4 and a rectangular resonant cavity on the back of the corresponding position, and a frequency adjustment mass for adjusting the natural frequency of the device is installed on the inner membrane of the resonant cavity Block 6.

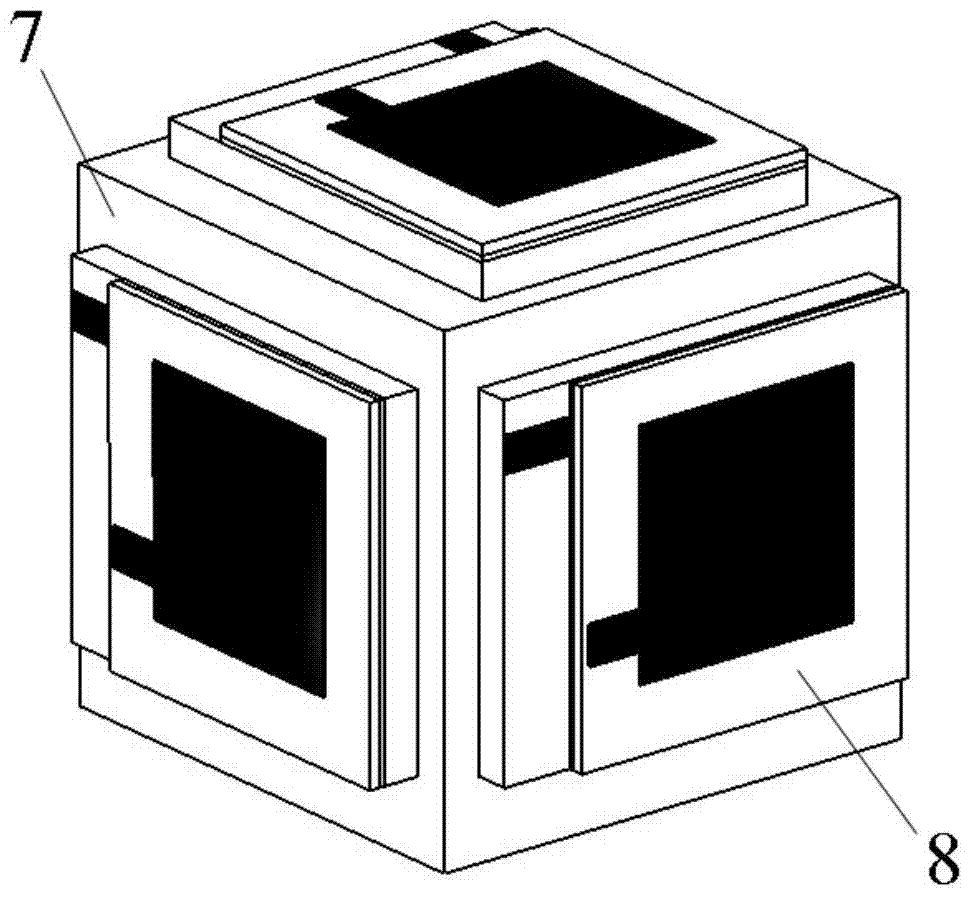

[0059] Such as image 3 As shown, the present embodiment includes a plurality of ultrasonic transducer modules 8 and a polymer structural frame 7 for mounting the ultrasonic transducer modules 8 .

[0060] Such as figure 1 As shown, in this embodiment, the ultrasonic transducer module 8 includes: a silicon substrate 1 (rectangular) with a back cavity, a rectangular piezoelectric material 4 bonded to the silicon substrate 1 through a conductive resin, and upper and lower electrodes Prepared by sputtering (ie bottom metal electrode 2 and top electrode 5). In this example, the overall size of the device is 5±2mm×6±2mm, the ...

Embodiment 2

[0092] Such as Figure 4 , 5 , 6, in the present embodiment, the ultrasonic transducer module 8 adopts a circular piezoelectric material 4 and a corresponding circular resonant cavity, and a frequency adjustment mass with the natural frequency of the adjustment device is pasted in the resonant cavity 6.

[0093] Such as Figure 4 As shown, the overall size of the ultrasonic transducer module 8 in this embodiment is 5±2mm×6±2mm, the thickness is 500±200μm, and the diameter of the resonant cavity is 4mm; 20μm, piezoelectric material 4 film diameter 5±2mm, thickness 40±20μm; such as Figure 5 As shown, the frequency adjustment mass 6 is a columnar nickel alloy with a size of 0.5±0.2mm in diameter and 4±2mm in height; Figure 6 As shown, the polymer structural frame 7 is a trapezoidal boss structure with a height of 2±1 mm, made of PDMS material, but not limited to this material.

[0094] In this embodiment, the ultrasonic transducer module 8 is assembled into a trapezoidal b...

Embodiment 3

[0124] Such as Figure 7 , 8 , 9, in this embodiment, the ultrasonic transducer module 8 adopts a circular piezoelectric material and a corresponding circular resonant cavity.

[0125] Such as image 3 As shown, the ultrasonic transducer module 8 in this embodiment is 5±2×6±2mm, the thickness is 500±200μm, and the diameter of the resonant cavity is 3±1mm; Figure 8 As shown, the silicon substrate has a margin of 40±20 μm after etching the resonant cavity, and the piezoelectric material 4 film has a diameter of 4±1 mm and a thickness of 40±20 μm; Figure 9 As shown, the polymer structural frame 7 is a rectangular structural support with a thickness of 2±1 mm, made of PDMS material, but not limited to this material.

[0126] In this embodiment, the ultrasonic transducer module 8 is assembled on both sides of the rectangular bracket, and its inner center is filled with medical gel. This structure is mostly used for implanting in relatively small parts, such as palms or wrists....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com