Method and device for quickly separating silicon-calcium slag

A technology for separation equipment and calcium-silicon slag, which is applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of high secondary reaction of alumina, slow settling speed of calcium-silicon slag, and long solid-liquid separation time, etc. Achieve the effect of increased separation speed, fast separation speed and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings, so that those of ordinary skill in the art can implement it after referring to this specification.

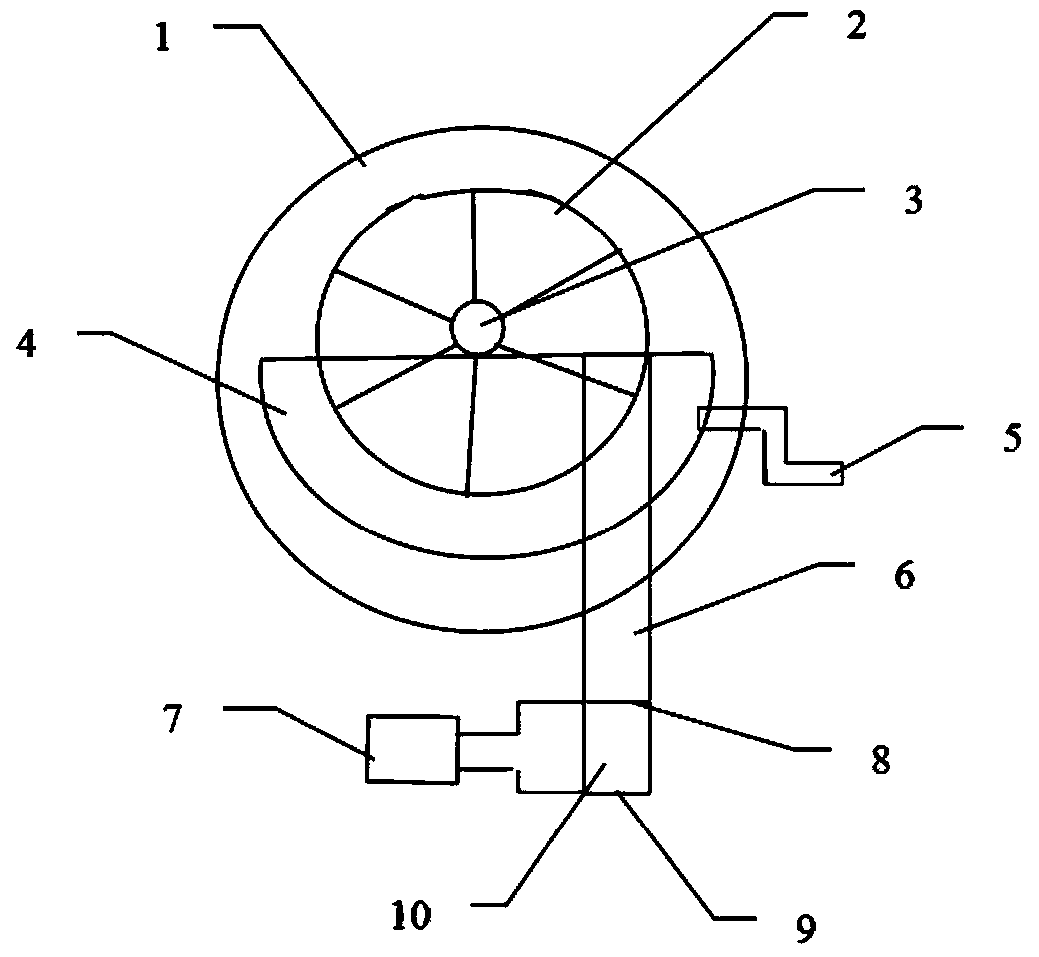

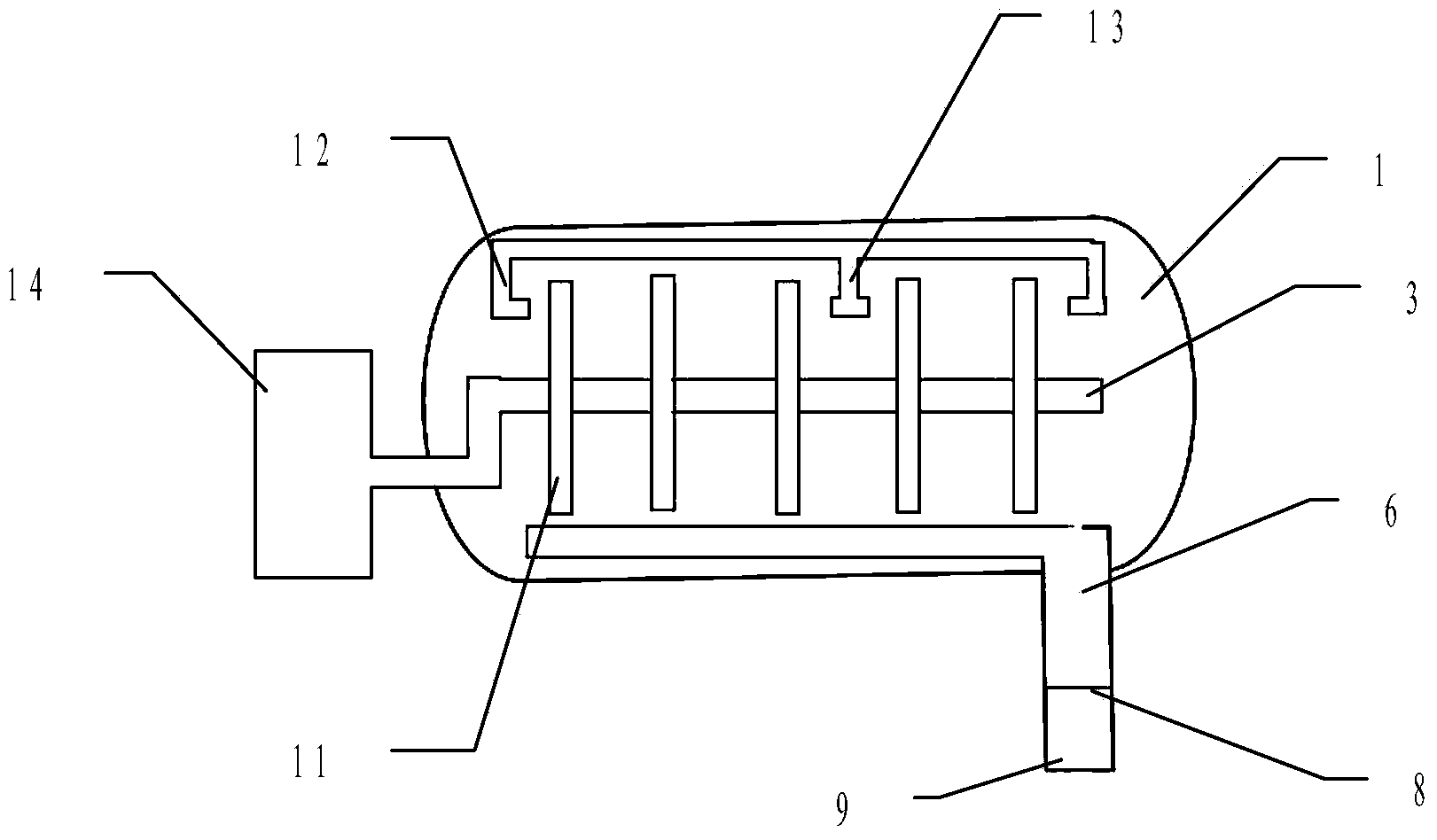

[0033] like figure 1As shown, the rapid separation equipment for silicon-calcium slag of the present invention includes: a high-pressure chamber 1, which is a closed hollow tank body, on which an air-filling pipe is arranged, and the air-filling pipe is connected with an air compressor to form a high-pressure closed system; Filtration device, which is arranged inside the high-pressure chamber, includes a slurry storage tank 4 and a rotating mechanism 3, wherein the rotating mechanism 3 is connected with a plurality of annular filter discs 11, and the annular filter discs 11 are composed of multiple Two fan-shaped filter plates 2 are concentrically arranged, and the annular filter discs 11 are arranged in series on the rotating mechanism 3. In addition, the rotating mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com